automatic steel t bar forming machine, ceiling system t grid making machine

-

Supplier: Cangzhou Zhongtuo International Trade Co., Ltd. -

Region: Hebei, China -

Contact: Mr Cary xu -

Price: $29800.00 / 1 - 1 sets

$28800.00 / 2 - 2 sets

$27800.00 / >=3 sets -

Min. Order: 1 set

| Supply capacity: | 1 set/automatic T-beam forming machine per month. | After-sales service provided: | Engineers can repair machinery overseas |

| Forming speed: | 30m/min | Material hardness: | 550MPa---350MPa |

| Material thickness: | 0.3---0.8mm | Number of stations: | 14 -16 Stations |

| Mechanical test report: | if | Production capacity: | 0-25m/min |

| Weight (kg): | 12500 | Tile Type: | T-Bar Forming Machine |

| Showroom location: | South Africa, Vietnam | Processing material: | gastrointestinal tract |

| place of origin; place of origin: | Hebei china | Marketing Type: | normal product |

| Health status: | new | payment terms: | L/C,D/P,D/A,T/T,O/A |

| Warranty: | 2 years | Core Components Warranty: | 1 year |

| Core components: | alarm lock | Video external inspection: | if |

| Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Manufacturing Plants, Machinery Repair Stores, Food and Beverage Plants, Farms, Restaurants, Home Use, Retail, Food Stores, Printing Stores, Construction Works, Energy and Mining, Food and Beverage Stores, Advertising Agencies | port: | Tianjin |

| brand: | Zhongtuo | Packaging Details: | 1. A 20-foot container for loading a machine with a manual uncoiler; 2. The whole wiped with anti-rust oil, the PLC controller covered with foam film; 3. Spare parts and some small parts are packed in a plastic tool box; 4 . All parts of the light metal structure machine are fixed by steel wire. |

| Packaging Preview: | Frame Thickness: | 25mm | |

| use: | ceiling and walls |

Automatic Steel T-Shape Forming Machine, Main T and Cross T for Plasterboard Ceilings

Brief Features:

1. CE/ISO certified products.

2. Personal data can be customized

3. Stable workandeasy to use

Zhongtuo automatic high-speed interchangeable steel T-shaped steel forming machine can be used to make main T-shaped and crossed T-shaped.

Main T column: Equipped with frequency conversion motor, production line speed: 30M perminute. Hydraulic automatic punching machine linkageMain forming machine, automatic punching. two heads andThe middle hole is punched and cut at the same time after forming.

Cross T bar: On-line production with inverter and servo motorSpeed: 30M per minute. Host constant speed, trackingServo tracking system, automatically tracking the main speed

Machine, automatic punching and cutting. two holesPunching and cutting at the same time after forming.

We also have machines for producing C-type, W-type, M-type purlins. Please find these machines in related products.

Check profile of main T-bar and cross T-bar:

Main SpecificationsT-Bar Forming Machine:

|

Uncoiler |

usage: It is used to support the steel coil and unfold it in a turntable manner. Passive uncoiler pulled by roll forming systemloading capacity: 1.5T Uncoiling width: 300mm Inner diameter: 450-550mm |

|

Inlet Beach |

usage: The raw material (steel plate) is manufactured and processed through the beach to ensure that the product is neat, parallel and uniform. For the function of the positioning angle iron, please refer to the equipment manual.feature: Ensure stability, accuracy and longevity. |

|

Master roll forming system |

usage: In order to maintain the shape and precision of the product, it adopts welded thin plate structure, motor deceleration drive, gear transmission (head and tail rolls, lower and upper rolls with gear transmission), roll surface polishing, hard plating, heat treatment and galvanizing treatment. Polished surface The heat treatment of the mold and the mold can also keep the surface of the mold plate smooth, and it is not easy to leave traces during stamping. Main body length: about 3500*800*1400Main part weight: 3 tons Voltage: 380V/50HZ 3-phase (according to customer requirements) roller holder: guide bar frame: Mid-plate welding commemorative arch type frame thickness: 25mm Drive method: Gear roller material: GCr12MoV Shaft material: 45# steel tempered shaft diameter: 40mm Number of rollers: 16 rollers Main power: 3kw cycloid planetary gear reducer) famous: Different sizes are produced by manually adjusting the shims. |

|

shearing mechanism |

Function: PLC controlled automatic cutting adopts hydraulic drive and automatic positioning to determine the size and cut the target product. Blade material: Gcr12MoV quenching power supply: Hydraulic power frame: strut type with rack and pinion system Limit switch: Non-contact photoelectric switch Element: It contains a set of cutting tools, a hydraulic oil tank and a cutting machine. |

|

Electronic control system:

|

1. Adopt Taiwan Delta PLC, inverter, touch panel to ensure high speed, stability, precision and long life. 2. Other electrical components are Delta 3. Equipped with movable switch, air circuit breaker, radiator, transformer and leakage protector, easy to operate and safe. |

Picture of steel T-beam forming machine:

1. Steel T-beam forming machine is bare; spare parts such as control box and hydraulic station are packed in plywood boxes.

2. Loading size: the machine body is about 10X1.8M, and other related components, generally need a 40' container.

ZT (Zhongtuo International Trade Co., Ltd.) is a company specializing in the field of cold forming machines and sheet metal processing. We are developing a wide range of cold forming machines for the manufacture of roof tiles, ceiling metal frames and pipe welding machines for the construction industry, the automotive industry, the packaging industry and more. ZT factory was founded in 1966 and its machines have been sold to more than 50 countries, trust us. Create your own world of cold forming with us.

Warranty: 1 year lifetime maintenance, installation and debugging: send professional engineers to install and debug,

Buyer pays our engineer $50/day per person and provides accommodation, food and round trip

Ticket fee. Installation days: about 5-7 days

contact me:

When you need to get a quote, please tell me the following information:

1. If you have, please show us the outline drawing.

2. Please tell us what kind of material you need to process and the thickness and width of the material.

3. Whether an uncoiler or a stacker is required.

4. The working speed you need.

Once we have this information, we will give you a quote as soon as possible.

...

-

CANMAX Manufacturer Construction Engineering High Quality 12m Manual Electric Concrete Pump Spare Parts Mobile Concrete Spreading Arm

-

Prefab Modular House Prefab Prefab House Equipment China 2021

-

China Manufacturer Manufacturing Machine Technology Production Line Guide Rail Telescopic Channel Roll Forming Machine Drawer Slide

-

Earthquake Resistant Precast Concrete House Making Machine, Structural House Equipment

-

160L 280L 350L Tilt Drum Concrete Mixer Mobile Mini Cement Mixer Price

-

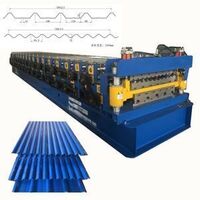

Best Selling Roller Shutter Slat Forming Machine / Roller Shutter Door Making Machine

-

Washbasin Pedestal Bathroom Casting Battery Stand

-

modern concrete house machines, fully prefab concrete houses

-

Building materials manufacturing machinery PU sandwich panel machine

-

Price of machine for forming rolls of production line of continuous polyurethane sandwich panels factory customized with ISO9001 / Ce / Sonc

Other Products

-

$70000.00 - $85000.00 / set

$70000.00 - $85000.00 / set -

$20000.00 / set

$20000.00 / set -

$5000.00 / set

$5000.00 / set -

$15000.00 - $23000.00 / set

$15000.00 - $23000.00 / set -

$20000.00 / set

$20000.00 / set -

$2500.00 / set

$2500.00 / set -

$24000.00 / set

$24000.00 / set -

$14000.00 / set

$14000.00 / set -

$10000.00 / set

$10000.00 / set -

$38000.00 / set

$38000.00 / set