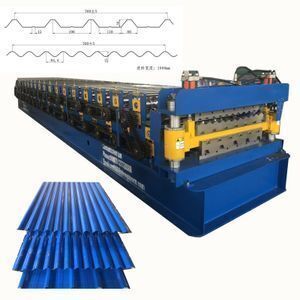

Double layer trapezoidal roof tile building material roll forming machine

-

Supplier: Cangzhou Zhongtuo International Trade Co., Ltd. -

Region: Hebei, China -

Contact: Mr Cary xu -

Price: $14000.00 /set -

Min. Order: 1 set

| Tile Type: | Colored Glaze Steel; | Place of Origin: | Hebei China; |

| Drive mode: | Chain; | Roller fixer: | Middle plate; |

| Weight: | 8.5T; | Diameter of shafts: | 80 mm; |

| Feeding width: | 1220mm; | Voltage: | 380V/50HZ/3Phase; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Dimension(L*W*H): | 7.5m*1.3m*1.3m; |

| Material of rollers: | 45# steel, surface hard chromium plating; | Material of shafts: | 45# steel; |

| Number of rollers: | 13+ 15; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Port: | XINGANG PORT TIANJIN CHINA; | Local Service Location: | Egypt,Canada,Turkey,United Kingdom,United States,Italy,France,Germany,Viet Nam,Philippines,Brazil,Peru,Saudi Arabia,Indonesia,Pakistan,India,Mexico,Russia,Spain,Thailand,Japan,Malaysia,Australia,Morocco,Kenya,Argentina,South Korea,Chile,UAE,Colombia,Algeria,Sri Lanka,Romania,Bangladesh,South Africa,Kazakhstan,Ukraine,Kyrgyzstan,Nigeria; |

| After-sales Service Provided: | Online support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support; | Packaging Detail: | NUDE PACKAGING IN ONE 40 GP CONTAINER; |

| Type: | Tile Forming Machine; | Marketing Type: | New Product 2020; |

| Video outgoing-inspection: | Provided; | Supply Ability: | 30 Set/Sets per Month Double trapezoidal layer roof tile building material machine; |

| Machine frame: | 350 H steel welded; | Package Preview: | ; |

| Use: | ROOF; | Rolling thinckness: | 0.3-1mm; |

| Production Capacity: | 8-12m/min; | Machinery Test Report: | Provided; |

| Brand Name: | Zhongtuo; | Showroom Location: | India; |

| Condition: | New; | Core Components: | Pressure vessel,Motor,Bearing,Gear,Pump,Gearbox,Engine,PLC; |

| Name: | Double trapezoidal layer roof tile building material machine; | Warranty: | 5 years; |

| Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; | Warranty of core components: | 3 years; |

| Key Selling Points: | Easy to Operate; | Material thickness: | 0.3-0.8 mm; |

| Certification: | CE/ISO9001; | Control system: | PLC; |

Double trapezoidal layer roof tile building material roll forming machine

Double layer roofing tile machine: can produce two type sheets, one corrugated sheet and one IBR sheet. The input material are both 1000 mm width with thickness 0.3-0.8mm. Machine speed 8-12 m per minute. With pre-cutting device and double inches chain. This machine cheaper and stable. Widely used in South America zone. Expecially Bolivia. We can also supply you the PPGI and GI coils. We know some good supplier. We can put the coils with the machine in the same container.

Double layer roofing tile machine profile drawings:

Our machine is customized, we will design and produce the machine as your personal requirements. Here below the profile drawings just for your reference only. This profile is the profile for our south africa customer. Different country have different profiles, if you want this machine please just give me your profile.

Double layer roll forming machine Work Flow:

Double layer roll forming machine Roll Forming Machine

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Length of the main part: About 8500 1650 1500 mm (L*W*H)

Weight of main part: 6.5 tons

Voltage : 380 V 50 HZ 3 PHASE(As customer’s need)

Roller fixer : Middle plate

Frame : 350 H steel welded

Drive mode: Chain

Material of rollers: 45# steel, surface hard chromium plating.

Material of shafts: 45# steel

Diameter of shafts: φ 80 mm

Number of rollers : 13 rollers(Up layer)15 rollers(Down layer)

Main power: 5.5 kw

Double layer roll forming machine Shearing Mechanism

Feature : Ensure stability, precision and cutting speed

It is used to make the step , the glazed tile's final formed.

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Function : Automatic cutting controlled by PLC

Material of blades : Cr 12 quenched

Power supply : Hydraulic power

Components: It contains one set of blade, one hydraulic tank and one cutter machine.

Double layer roll forming machine Hydraulic Station

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

Hydraulic motor Power: 4 kw

Hydraulic oil: 46# hydraulic oil

Volume: 30 L

Components: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes. and two sets of electromagnetism valves.

Double layer roll forming machine Electric Control System

1. Adopted PLC , transducer, touch panel to ensure high speed with stability, precision and lifetime.

2. Voltage: 380V 50 HZ 3 PHASE (As customer’s need)

3. Language: English and Chinese

4. Automatic length measurement

5. Automatic quantity measurement

6. Length Tolerance: 3 m±1.5 mm

7. Length inaccuracy can be amended easily.

8. Unit of length: millimeter (switched on the control panel)

9. Computer operating panel: touching screen and button together.

Double layer roll forming machine Warranty

1. One year warranty, whole life technical support.

2. Installation & adjustment : We can take a video for the customer and the customer can also come to our factory, we can train customer how to install and adjust the machine.

3. Oversea service: the buyer should charge of visa, return ticket, food and accommodation overseas and USD50/person/day salary.

1. Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine. It can produce more than 6 kinds of panels.

2. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.

3. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

4. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't repair,we can send the new parts replace the broken parts freell,but you need pay the express cost yourself.if after warranty period,we can through negotiationfor to solve the problems,and we supply the technical support for the whole life of the equipment.

5. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich experience in transport.

6. You are trade company or factory?

We are trade company but we also have own factories. Building trade company is just for exporting various types of cold roll forming machines.

7. Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend time and money on developing How to make machines much more automatic, accurate and high quality. We can make sure thatour machine could use more than 20 years without any problem. We can provide 2 years free qualityassurance.

8. How long the machine could be made?

Normally speaking, welded pipe making machine could be made without 45 working days. If you need machines in a hurry, we can make it for you less than a month.

-

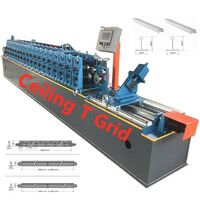

Three-layer molding machine

-

Low cost clay brick making machine manual type clay brick making machine suitable for different sizes and different types of bricks

-

1000 type roof panel glazed tile pressing machine

-

HMS900 Electric Tile Cutter with CE Certification 1000mm Cutting Length, Marble Saw

-

Sheet metal building materials manufacturing machinery parts

-

Wall and color steel tile type polyurethane sandwich roof panel manufacturing machine

-

Terrazzo brick press

-

2022 Popular Manual Clay Roof Tile Making Machine Floor Tile Making Machine Roof Floor Tile Press Forming Machine

-

Galvanized floor deck forming machine

-

Automatic metal Ibr shingle trapezoidal shingle roller press machine for sale in South Africa

Other Products

-

$70000.00 - $85000.00 / set

$70000.00 - $85000.00 / set -

$20000.00 / set

$20000.00 / set -

$5000.00 / set

$5000.00 / set -

$15000.00 - $23000.00 / set

$15000.00 - $23000.00 / set -

$27800.00 - $29800.00 / set

$27800.00 - $29800.00 / set -

$20000.00 / set

$20000.00 / set -

$2500.00 / set

$2500.00 / set -

$24000.00 / set

$24000.00 / set -

$10000.00 / set

$10000.00 / set -

$38000.00 / set

$38000.00 / set