Steel Plate Embossing Machines Steel Plate Embossing Machines Metal Embossing India Hot Products 2020 Tube Mill Line 5 Years CN; HEB

-

Supplier: Cangzhou Zhongtuo International Trade Co., Ltd. -

Region: Hebei, China -

Contact: Mr Cary xu -

Price: $20000.00 /set -

Min. Order: 1 set

| Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Mechanical Repair Stores, Manufacturing Plants, Food and Beverage Plants, Farms, Restaurants, Home Use, Retail, Food Stores, Printing Stores, Construction Works, Energy and Mining, Food and Beverage Stores, Advertising Agencies | port: | Tianjin |

| After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services | Main selling point: | high accuracy |

| Health status: | new, new | Supply capacity: | 20 sets per month |

| Embossing Roller: | 440*1150 | Packaging Details: | The uncoiler is covered with plastic film and the spare parts are in the carton. |

| Mechanical test report: | if | Type of machine: | Tube grinding line |

| Raw material thickness: | custom made | ability: | 10 tons |

| Core Components Warranty: | 2 years | Local service location: | India |

| Core components: | PLC, engine, bearing, motor, gear, pump | Marketing Type: | Hot Products of 2020 |

| speed: | 25m/min | Showroom location: | India |

| use: | Metal Embossing | brand: | Zhongtuo, Zhongtuo |

| Drive System: | Hydraulic/Manual/Electric | Warranty: | 5 years |

| payment terms: | letter of credit, wire transfer | place of origin; place of origin: | Hebei china |

| After-sales service provided: | Online support, on-site installation and commissioning training, on-site maintenance and repair services, video technical support | Video external inspection: | if |

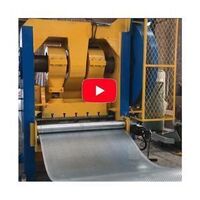

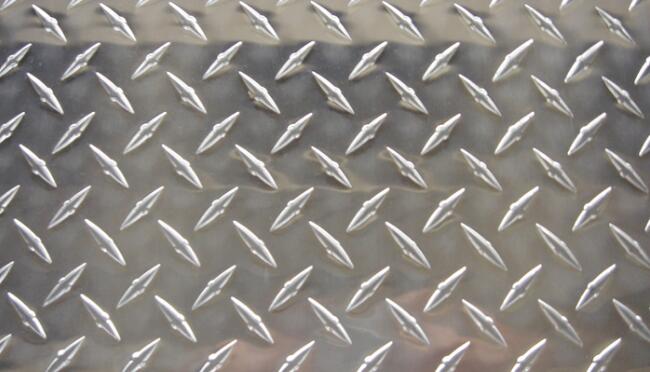

steel plate embossing machine steel plate embossing machine

Steel wallboard embossing machine embossing rolls can make metal structural corners for building structures.

Custom grating floor plate embossing machines are used to produce sheets and arabesques with exquisite patterns and graphics.

Different shapes of checkered plates can be used for many decorative buildings and also for anti-skid floors, especially for ships.

Zhongtuo metal floor embossing machine can help you emboss different patterns on metal, which can be used in many constructions, such as: walls, panels or others.

The alloy embossing roll for steel plate embossing roll is mainly composed of two large rolls.

The rollers are patterned, so when the rollers roll and the sheet between the two runs, the pattern appears on the sheet.

The best quality steel embossing roll floor embossing machinery can be done manually by workers, from feeding and embossing,

It is also composed of PLC control box fully automatic.

Here are some pictures of floor embossing machines for your reference:

Below are some specification details of alloy embossing rolls for steel plate embossing rolls, please check:

Embossing roller: ø440*1150;

Bearing: Torrington spherical roller bearing, TWB 3003136;

Adjust the embossing thickness via the dial.

Bearing box: 400*400*160mm.

Drive: 11kw AC motor,

Reducer: BWED53-17*11-11KW 4P

Speed: 1-10m/min

Pressure method: hydraulic system, 2 ø150 oil cylinders

Enclosed protective cover, safety device. Emergency stop switch

Embossing roller surface hardness: HRC 58~62

Hardness surface depth: 5-10mm

Embossing roller material: 60CrMnMo

Pattern laser engraving as customer's sample;

If you need a set of alloy embossing rolls for steel plate embossing rolls, we can design the machine and quote and send it to you.

But we need you to provide the following details:

1 sheet of material

2 Embossing speed

3 sheet thickness

4 Embossing pattern drawing

Standard parameters of this metal iron steel plate embossing roll equipment:

|

Model |

ZT-S1000 |

ZT-S1400 |

ZT-S1600 |

ZT-S1900 |

|

Dimensions (mm) |

2900*1200*1500 |

3300*1200*1500 |

3500*1200*1500 |

3800*1200*1500 |

|

Roller size |

φ350*1000mm |

φ380*1400mm |

φ400*1600mm |

φ450*1900mm

|

|

Roller material |

42CrMo |

42CrMo |

42CrMo |

42CrMo |

|

Roller hardness |

HRC55-58 |

HRC55-58 |

HRC55-58 |

HRC55-58 |

|

Embossing method |

Simultaneous embossing of upper and lower rolls |

Simultaneous embossing of upper and lower rolls |

Simultaneous embossing of upper and lower rolls |

Simultaneous embossing of upper and lower rolls |

|

Embossing regulations |

by screw |

by screw |

by screw |

by screw |

|

Motor power (KW) |

7.5 |

11 |

15 |

15 |

|

Line speed |

0-18m/min |

0-30m/min |

0-40m/min |

0-45m/min |

-

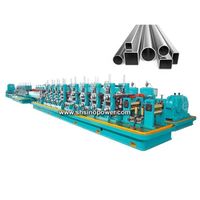

Erw MS pipe making machine for manufacturing steel pipe metal pipe production line manufacturer

-

Fly cold saw gear box

-

China factory steel pipe factory stainless steel pipe making machine/pipe

-

HFH Street Lamp Pole Automatic Welding Production Line

-

Manufacturer Price ERW Tube Making Machine

-

High frequency welding stainless steel round tube welding machine tube mill equipment

-

Foshan YXH round square rectangle available stainless steel pipe rolling line steel pipe making machine iron pipe making machine

-

Metal Tube Mill / ERW Steel Tube Mill

-

High quality big discount high frequency welded steel pipe making machine for iron carbon galvanized steel pipe

-

Steel pipe/tube forming machine

Other Products

-

$70000.00 - $85000.00 / set

$70000.00 - $85000.00 / set -

$5000.00 / set

$5000.00 / set -

$15000.00 - $23000.00 / set

$15000.00 - $23000.00 / set -

$27800.00 - $29800.00 / set

$27800.00 - $29800.00 / set -

$20000.00 / set

$20000.00 / set -

$2500.00 / set

$2500.00 / set -

$24000.00 / set

$24000.00 / set -

$14000.00 / set

$14000.00 / set -

$10000.00 / set

$10000.00 / set -

$38000.00 / set

$38000.00 / set