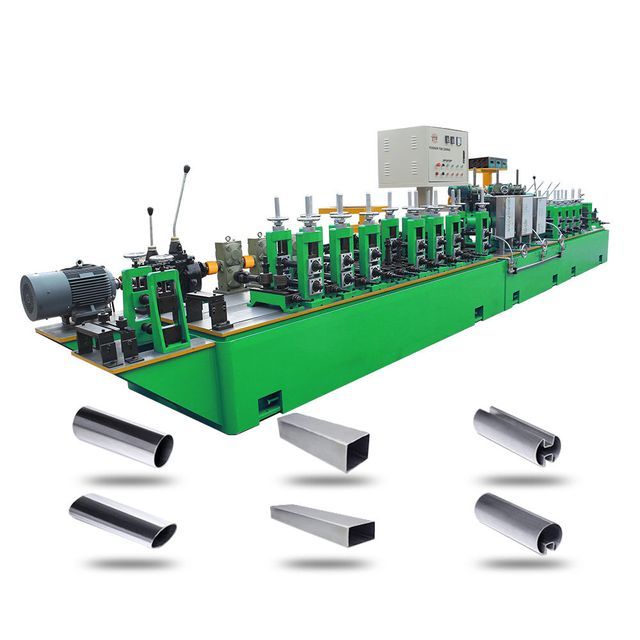

Foshan YXH round square rectangle available stainless steel pipe rolling line steel pipe making machine iron pipe making machine

-

Supplier: Foshan YXH Tube Mill & Mould Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Suanna Feng -

Price: $28000.00 / 1 - 2 sets

$27500.00 / 3 - 4 sets

$27000.00 / >=5 sets -

Min. Order: 1 set

Product details

| brand: | YXH pipe making machine | Video shipment inspection: | if |

| Core component warranty: | 1 year | Core components: | PLC, engine, bearing, gearbox, motor, gear |

| Key words: | steel pipe making machine | payment terms: | L/C, Western Union, D/P, D/A, T/T |

| operator: | 1 person operates 2 machines | Function: | Stainless steel pipe production line |

| Type of machine: | Tube mill production line | Showroom location: | not any |

| Main selling points: | long lasting | Round tube thickness: | 0.2-2.0 mm |

| Mechanical test report: | according to actual condition | Pipe shape: | round/square/rectangular |

| Square/rectangular pipe dimensions: | 10*10-40*40/10*20-30*50 mm | Weight (kg): | 6000 |

| Round tube diameter: | 15.88-50.8 mm | Health status: | new |

| Package preview: | port: | Foshan, Guangzhou, Shenzhen or depends on your needs | |

| Supply capacity: | 30 sets per month | useful life: | more than 10 years |

| Square/rectangular tube thickness: | 0.3-2.0 mm | Origin: | Guangdong, China |

| Warranty: | 1 year | Marketing Type: | normal product |

| Pipeline application: | decorative tube | Packaging Details: | Steel pipe machines must be secured with wooden battens and steel wires to prevent improper transportation |

Stainless steel pipe making machine

Foshan YXH Tube Mill & Mold Co.,Ltd offers different Stainless Steel Tube Making Machines Tube Production Line Manufacturing Machines, covering from4 mm to 426 mm , with a thickness of0.2 mm to 8.0 mmRound pipe, square pipe, rectangular pipe, oval pipe and other irregular pipes.

Interested in our machines? contact us!

Product parameters

type | Pipe diameter (mm) | round tube thickness (mm) | square tube thickness (mm) | capacity (m/min) | weight (T) | Installation (L*Wm) | Voltage |

SZG40 | 8-31.8 | 0.2-2.0 | 0.3-1.5 | 1-20 | 5.5 tons | 20*1.0m | 220V/380V/415V/440V |

ZG40 | 15.88-50.8 | 0.2-2.0 | 0.3-1.5 | 1-15 | 6 tons | 21.5*1.1m | |

BBZG40 | 15.88-50.8 | 0.2-2.0 | 0.3-2.0 | 1-15 | 6.5 tons | 21.5*1.1m | |

BZG40 | 12.7-63.5 | 0.3-2.0 | 0.3-2.0 | 1-10 | 6.5 tons | 21.5*1.1m | |

ZG50 | 25.4-76.2 | 0.4-3.0 | 0.4-2.5 | 1-7 | 10 tons | 24*1.2m | |

ZG60 | 38.1-114 | 0.5-3.0 | 0.5-3.0 | 1-5 | 12 tons | 26*1.4m |

Mechanical Parts

Uncoiling & Forming Department

The steel coil is installed on the uncoiler, and the uncoiler loads the steel strip and transports it to the forming section, and the steel strip passing through the forming section is formed into a pipe.

welded part

The formed pipe will have gaps, reach the welding section, and connect the weld seam through the welding torch. become a sealed tube.

grinding section

After welding, the weld seam is slightly raised, and the excess part is ground off after the grinding section. The tube will become smooth.

Sizing, straightening and cutting

The pipe is further fixed in the sizing and straightening section, passes through the winch head, and finally enters the cutting section to cut the pipe.

click to contact

machine advantage

Industrial gearbox, dual motors can provide more powerful power to support pipe manufacturing, making pipe manufacturing faster and more precise.

click to contact

more advantages

Why choose us:

Our 4414 array design can greatly reduce scratches, and our molds are produced using the best materials, as well as special mold mounting array designs.

For more information click to contact

VIEW MORE

You may like

-

Erw MS pipe making machine for manufacturing steel pipe metal pipe production line manufacturer

-

Fly cold saw gear box

-

China factory steel pipe factory stainless steel pipe making machine/pipe

-

HFH Street Lamp Pole Automatic Welding Production Line

-

Manufacturer Price ERW Tube Making Machine

-

High frequency welding stainless steel round tube welding machine tube mill equipment

-

Metal Tube Mill / ERW Steel Tube Mill

-

High quality big discount high frequency welded steel pipe making machine for iron carbon galvanized steel pipe

-

Steel pipe/tube forming machine

-

Factory experienced metal flower decorative tube stamping machine

Other Products

-

$18645.00 - $19250.00 / set

$18645.00 - $19250.00 / set -

$14000.00 / set

$14000.00 / set

Related Search

304 stainless steel csk head machine screw

stainless steel juice dispenser machine

stainless steel sheet cutting machine

stainless steel noodle making machine cheap price

stainless steel manual juicer machine

horizontal stainless steel milk cooling machine

stainless steel drum washing machine for sale

dn 35 stainless steel spot welding machine

stainless steel slush smoothie machine

stainless steel saw table machine