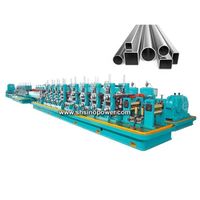

High quality big discount high frequency welded steel pipe making machine for iron carbon galvanized steel pipe

-

Supplier: Shanghai Honcang Industrial Limited -

Region: Shanghai, China -

Contact: Mr SHAWN XU -

Price: $135000.00 /unit -

Min. Order: 1 unit

| thickness: | 0.6 - 2.5mm steel pipe | weight: | 45 tons |

| Video shipment inspection: | if | payment terms: | wire transfer |

| Voltage: | 220/380/415/420/440V | Local service location: | not any |

| Type of machine: | Tube mill production line | After warranty service: | Video technical support, online support, spare parts, on-site maintenance and repair services |

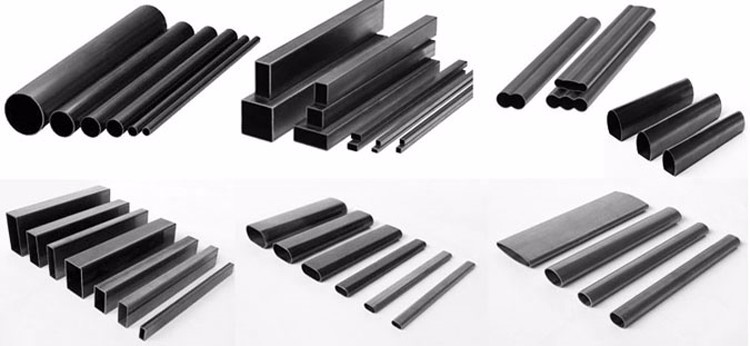

| Pipe shape: | Round tube, square tube, square tube, LTZ profile | Mechanical test report: | if |

| Control System: | Siemens/Taiwan PLC control system; | Health status: | new |

| Warranty: | 1 year | Pipe diameter: | 12.7 -76 mm steel pipe |

| Origin: | Jiangsu, China | After-sales service provided: | On-site installation, commissioning and training, on-site maintenance and repair services, online support, video technical support |

| Packaging Details: | Iron pipe carbon steel pipe straight seam steel pipe equipment use | Showroom location: | not any |

| Marketing Type: | normal product | Certification: | ISO 9001: 2008 ; CE certification |

| Pipe material: | Carbon Steel, MS Steel, Galvanized Steel, Iron | Applicable industries: | Home furnishing, construction engineering, building materials stores, advertising agencies, machinery repair shops, manufacturing plants |

| Main selling points: | competitive price | Core components: | Bearings, gearboxes, gears |

| port: | Chinese port | Core component warranty: | 1 year |

ERW pipe making machine | Slitter | cut length line |

Steel Roll Forming Machine | Roll film production line | Coil color coating line |

Why choose us?

1.30 years of metal processing equipment development

2.15 years of export experience, serving hundreds of customers in 40 countries

3. First-class engineer team, advanced production technology, bring maximum return to customers.

4. 24-hour online service, excellent service system

The high-frequency welded pipe machine is the main equipment of the welded pipe production line integrating uncoiler, strip feeding, roll forming and sizing, high-frequency solid welding, cutting and storage. Below are the detailed specifications of our pipe production lines.

1: What kind of pipes can our pipe factory produce?

1. Oil and gas pipe 7. Wire and cable protection tube

2. Heating pipe 8. Structural support steel pipe

3. Low-pressure process pipes 9. Industrial steel pipes

4. Low-pressure fire-fighting pipeline 10. Decoration pipeline

5. Sewage pipe 11. Water pipe

6. Steel scaffold pipe 12. Construction pipe

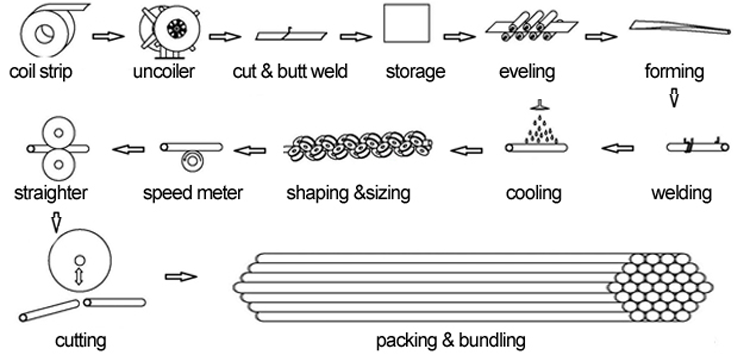

2. Our tube mill flow chart

ISO/CE MS cast iron pipe machine production line 8-219mm ERW pipe machine standard flow chart:

Step 1: Uncoiler

Function: To support the tension of the rolled plate and strip for the straight seam pipe mill production line, it is composed of a frame, a main shaft, an increasing rotation reel, and a brake.

There are 3 types: pneumatic, hydraulic and manual.

Step 2: Shear Butt Weld

2 types: automatic and manual

Function: Cut off the end of each roll of steel strip, and then weld them together, so that the pipe welding machine production line can continue to produce.

Step 3: Strip the Accumulator

Function: Store strips to maintain continuous production.

2 types: horizontal/vertical

Advantages: Horizontal type can have larger storage space. Uprights are much cheaper and take up less space.

Step 4: Forming the Parts.

Function: Forming strip into pipe

Advantage:

>Advanced molding technology

>One-time forming platform

>Reliable quality gearbox

>Siemens Bede Motor

Step 5: High Frequency Soldering

Function: welding pipes, different thickness and diameter, power of HF welder welder

Our advantage: We choose the best welding machine in China: Sanyi brand.

Step 6: Size Section

Function: Dimensional pipe to exact dimensions

Advantage:

>Advanced sizing technology

>One-time forming platform

>Reliable quality gearbox and Siemens Beide motor

> High precision, small pipe size error

Step 7: Flying Saw/Cold Saw

Function: Cut the tube grinder tube to a suitable length.

Flying saw: easy to operate, less investment.

Cold sawing: Noiseless, burr-free cutting precision and sections.

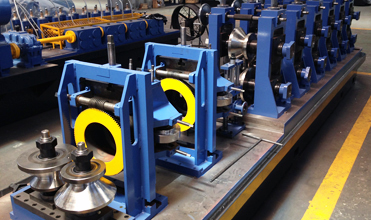

3. Detailed picture of pipe making machine

With excellent product quality, CLP Group has successfully provided world-class products and services to more than 40 countries and regions around the world, such as: Poland, Spain, Russia, Yugoslavia, Ukraine, Turkey, Egypt, Saudi Arabia, India, Vietnam, Malaysia, Thailand, Philippines, Pakistan, Kazakhstan, Ethiopia, etc.

Below is ourStandard seriesour pipe making machines,We also accept customization.

Model | round tube | Square and Rectangular Tubes | speed | ||||||

diameter/mm | Thickness/mm | square size/mm | Re-size/mm | Thickness/mm | |||||

SP12 | 8-16 | 0.2-0.6 | 20-120m/min | ||||||

SP16 | 8-25 | 0.2-1.0 | 7×7-20×20 | 7×7-25×15 | 0.2-0.8 | 20-120m/min | |||

SP25 | 8-32 | 0.3-1.3 | 7×7-25×25 | 7×7-30×20 | 0.3-1.0 | 20-120m/min | |||

SP28 | 8-42 | 0.3-1.8 | 7×7-30×30 | 7×7-40×20 | 0.3-1.3 | 20-120m/min | |||

SP32 | 16-50.8 | 0.6-2.0 | 12×12-40×40 | 14×10-50×30 | 0.6-1.6 | 20-120m/min | |||

SP45 | 19-63.5 | 0.6-2.5 | 15×15-50×50 | 20×10-70×30 | 0.6-2.0 | 20-120m/min | |||

SP50 | 19-76 years old | 0.6-2.5 | 15×15-60×60 | 20×10-80×40 | 0.6-2.0 | 20-120m/min | |||

SP60 | 19-76 years old | 0.6-3.0 | 15×15-60×60 | 20×10-80×40 | 0.6-2.5 | 20-100m/min | |||

SP76 | 25-80 | 1.2-4.0 | 20×20-62×62 | 30×10-84×40 | 1.2-3.0 | 20-70m/min | |||

SP90 | 32-90 | 1.5-4.5 | 25×25-70×70 | 30×20-90×50 | 1.5-3.5 | 20-60m/min | |||

SP115 | 38-115 | 2.0-5.0 | 30×30-90×90 | 40×20-120×60 | 2.0-4.0 | 20-60m/min | |||

SP165 | 60-165 | 2.0-6.0 | 45×45-130×130 | 60×30-150×100 | 2.0-4.5 | 15-50m/min | |||

SP219 | 90-219 | 3.0-8.0 | 70×70-170×170 | 100×40-200×140 | 3.0×6.0 | 15-50m/min | |||

Please click here to send me an inquiry

return home

-

Erw MS pipe making machine for manufacturing steel pipe metal pipe production line manufacturer

-

Fly cold saw gear box

-

China factory steel pipe factory stainless steel pipe making machine/pipe

-

HFH Street Lamp Pole Automatic Welding Production Line

-

Manufacturer Price ERW Tube Making Machine

-

High frequency welding stainless steel round tube welding machine tube mill equipment

-

Foshan YXH round square rectangle available stainless steel pipe rolling line steel pipe making machine iron pipe making machine

-

Metal Tube Mill / ERW Steel Tube Mill

-

Steel pipe/tube forming machine

-

Factory experienced metal flower decorative tube stamping machine

Other Products

-

$213750.00 / unit

$213750.00 / unit -

$320000.00 / unit

$320000.00 / unit -

Square pipe roll forming machine used Automatic steel ERW pipe mill line machine to make square tube$122000.00 / set

Square pipe roll forming machine used Automatic steel ERW pipe mill line machine to make square tube$122000.00 / set