Steel coil slitting machine Steel plate slitting line Metal slitting machine

-

Supplier: Cangzhou Zhongtuo International Trade Co., Ltd. -

Region: Hebei, China -

Contact: Mr Cary xu -

Price: $85000.00 / 1 - 1 sets

$75000.00 / 2 - 2 sets

$70000.00 / >=3 sets -

Min. Order: 1 set

| width: | 500-1500(Max) | Health status: | new |

| .Line speed: | 0-60m/min | Coil weight (T): | 10 tons |

| Warranty: | 1 year | product name: | Roll Slitter |

| Core components: | PLC, gear | Cutting thickness: | 0.5-2.0mm |

| Voltage: | 380v/50hz/3ph | Packaging Details: | All parts of the sheet and coil slitting machine are fixed by steel wires. |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram, Cash | Material Thickness (mm): | 0.2 - 3mm |

| brand: | Zhongtuo | Certification: | International Organization for Standardization |

| Number of slitting lines: | 3 - 5 | type: | Shearing machine |

| weight: | 18 tons | Supply capacity: | 15 sets per month |

| Main selling points: | long lasting | .Length tolerance: | ≤±0.5mm/2000mm |

| Showroom location: | India | After-sales service provided: | Engineers available to service machinery overseas |

| After warranty service: | Video technical support, online support, spare parts, on-site maintenance and repair services | Dimensions (L*W*H): | 25*7 meters |

| Core component warranty: | 2 years | Cutting width (mm): | 100 - 1000mm |

| Video shipment inspection: | if | Mechanical test report: | if |

| Cutting speed (m/min): | 10 - 50mm | rated power: | About 100Kw |

| Origin: | Hebei china | Local service location: | not any |

| Marketing Type: | New Products 2020 | Diagonal line tolerance: ≤±1mm/2000mm: | ≤±1mm/2000mm |

| port: | Tianjin | Applicable industries: | Building material stores, manufacturing plants, construction projects |

Steel coil slitting machine Steel plate slitting line Metal slitting machine

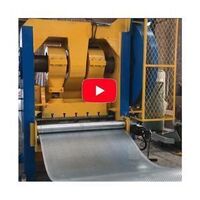

Brief introduction of steel plate coil slitting machine:

A roll slitter is a longitudinal slitting line for slitting sheet metal.Coil slitters uncoil sheet metal coils, then slit (cut) the metal sheet lengthwise, and then reel the slit sheet metal to obtain narrower sheet metal coils. Coil slitter is a service center for sheet metal strip coil cutting, press stamping stamping, metal lath processing, etc.

Slitting machine technical parameters:

1. Specifications:

a. Applied to: HR, CR

b. Tensile strength: b≤500Mpa, S≤300Mpa

c. Thickness: 0.5-2.0mm

d. Width: 500-1500 (maximum)

e. Coil inner diameter: 508mm

F. Coil outer diameter: 1600mm (maximum)

g. Weight: 15T (Max)

H. Straightening roller diameter: 65mm

I. Leveling roller distance: 70mm,

j. Leveling roller material: GCr15, hardness: HRC55-60

k. Total machine weight: about 30T

2. Finished product parameters:

a. Diagonal tolerance: ≤±1mm/2000mm

b. Length tolerance: ≤±0.5mm/2000mm

3. Other parameters:

a. Power supply: 380V/50Hz/3Ph

b. Line speed: 0-60m/min

c. Capacity: about 100Kw

d. The entire production line covers an area (approximately) 25m(L)X7m(W)

e. Operators: 1 technician, 2 general workers

F. Machine color: grass green

Roll slitting machine components:

1. Hydraulic car

2. Hydraulic uncoiler

3. Slitting machine

4. Scrap winder

5. Tension rack

6. Hydraulic recoil

7. Empty car

8. Hydraulic control system

9. Electric control system

Slitting machine workflow

Detailed introduction of slitting machine

|

Hydraulic uncoilerhave a car It uses hydraulic cylinders to allow the decoiler to expand and adapt to the inner diameter of the coil. It is equipped with a cantilever. Inner diameter: 508mm. Maximum width: 1500mm 15 tons capacity (maximum) |

|

Pre-leveler It can straighten the rough plate and guide plate just entering the process Mechanical structure: It consists of two rows of leveling rollers, two rows of intermediate rollers, two sets of rollers, driving device, two pinch rollers and a frame. Each roller is driven at both ends by roller pin bearings, The working roller gap is electrically adjusted, controlled by 2 handwheels to ensure the leveling quality. Drive mode: 55kw frequency conversion speed regulation motor drive Rolling process: hardened HRC55-60-fine grinding-hard chrome plating automatic lubrication system |

|

Servo precision straightening machine It is controlled by a servo motor for adjustment of high-speed feed and precise length control. Operation is done on a console with programmable controls. Drive model: 15KW servo motor |

|

High Speed Paper Cutter 1). Width range: 200--1300mm 2). Line width: ±1mm 3). Cutting speed: 50m/min 4). The width can be changed. 5). Cutting material: Cr12MoV. Cutting blade hardness: HRC5860. 6). Slitting: 2~3mm 6 wires. 7). Quantity of blades: 10 sets. 8). Side waste width: 3-15mm 9). The value of leftover material: ±0.5mm 10). Quantity of edge waste: 2 pieces 11). Cutting power: 37KW, 1000r/min, equipped with ZQ750 reducer. |

|

Pneumatic stacking device The boards are stacked pneumatically, and the lifting is controlled by PLC. Three 0.75kw motors drag to adjust the width and length. Equipped with wind device, cooperate with high-pressure fan to prevent paper friction. Air source pressure: 0.4-0.6Mpa. Processing capacity: 1m³/min. |

|

electronic system 1). Screen: 3.2 inch button screen 2). PLC: Delta |

Equipment Basic Engineering

The seller will provide the buyer with the equipment infrastructure plan within 60 days after signing the contract.

The construction and monitoring of all foundation works for the equipment are within the Buyer's control.

The foundation holes are reserved holes, which match the equipment anchor holes.

After the equipment is installed, the buyer is responsible for grouting the foundation holes.

Comment

1. In ensuring the main technical parameters and installation level of the equipment, the user has the right to modify some parameters during the consulting and manufacturing process

2. The seller needs to provide the following items

(1) Mechanical foundation installation drawing, production line layout and operation manual.

(2) All the following spare parts are provided with the machine, if there are spare parts, the customer should prepare them by himself.

-

Fully Automatic Narrow Metal Strip Slitting Machine Min. 4mm narrow tape roll in China

-

sheet metal reel slitting line cr slitter

-

Jopar Automatic Coil Slitting Machine Stainless Steel Sheet Slitting Machine

-

1250mm simple carbon steel slitting machine color steel metal sheet coil slitting/slitting machine

-

Fully automatic metal steel coil slitting and winding forming machine production line

-

Automatic Metal Steel Coil Slitting Machine For Sale Metal Strip Cutting Machine Steel Plate Coil Cutting Machine Price

-

Simple slitting machine coil metal steel slitting machine

-

1.5mm steel plate slitting machine with PLC control system

-

Factory Price High Speed Steel Coil Slitting Machine

Other Products

-

$20000.00 / set

$20000.00 / set -

$5000.00 / set

$5000.00 / set -

$15000.00 - $23000.00 / set

$15000.00 - $23000.00 / set -

$27800.00 - $29800.00 / set

$27800.00 - $29800.00 / set -

$20000.00 / set

$20000.00 / set -

$2500.00 / set

$2500.00 / set -

$24000.00 / set

$24000.00 / set -

$14000.00 / set

$14000.00 / set -

$10000.00 / set

$10000.00 / set -

$38000.00 / set

$38000.00 / set