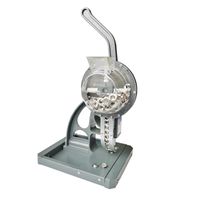

Metal sheet perforated machine steel plate punching machine High speed rotary punching machine

-

Supplier: Cangzhou Zhongtuo International Trade Co., Ltd. -

Region: Hebei, China -

Contact: Mr Cary xu -

Price: $2500.00 /set -

Min. Order: 1 set

| Place of Origin: | Hebei China; | Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; |

| Function: | Steel Metal Punching; | Voltage: | 220 380 415 and other voltage can be made; |

| Processing material: | Stainless Steel Mild Steel Aluminum; | Certification: | CE ISO; |

| Name: | Portable Steel Plate Punching Machine; | Warranty of core components: | 2 years; |

| Motor Power (kW): | 37KW; | Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; |

| Usage: | Metal Sheet Punching Cutting Bending; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Warranty: | 2 years; | Key Selling Points: | High Productivity; |

| Video outgoing-inspection: | Provided; | Condition: | New; |

| Machinery Test Report: | Provided; | Control system: | PLC(Touch Screen); |

| Pressure capacity: | 50-250 tons; | Packaging Detail: | The Metal sheet perforated machine steel plate punching machine High speed rotary punching machine will be packaged by the plastic film and then loaded into the container.; |

| Power Source: | Hydraulic; | Weight (T): | 15; |

| Dimension(L*W*H): | 8500*1500*1200; | Slide Stroke (mm): | 1000; |

| Brand Name: | ZT; | After-sales Service Provided: | Online support,Video technical support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service; |

| Application: | Decorate panel punching; | Local Service Location: | India; |

| Machine Type: | Punching Machine; | Keyword: | Metal sheet punching machine; |

| Model Number: | 250 TONS; | CNC or Not: | CNC; |

| Core Components: | Bearing,Pump,Gear,Motor,PLC,Engine; | Marketing Type: | Ordinary Product; |

| Product name: | Steel Hole Punching Machine; | Showroom Location: | India; |

| Advantage: | High Efficiceny; |

Metal sheet perforated machine steel plate punching machine High speed rotary punching machine

Metal coil width is 1220 mm, thickness is 0.3-0.8mm, the usages of the perforated metal sheet is for decorate metal panel.

whole line of Metal sheet perforated machine steel plate punching machine High speed rotary punching machine is processing the perforated sheet from de-coiler, straigntener, punching, cut to length and re-coiling.

The Metal sheet perforated machine steel plate punching machine High speed rotary punching machine can be designed with 50 tons, 100 tons, 200 tons, 250 tons and higher tons according to the holes size and sheet width and thickness.

below is the specification of each perforated machine.

50T-1 500kn 1000mm 72times/min 4kw or as required

50T-2 500kn 1000mm 72times/min 5.5kw or as required

Type Perforating Strength Feeding Width Perforating Speed Main Engine

100T-1 1000kn 1000mm 72times/min 7.5kw or as required

100T-2 1000kn 1250mm 72times/min 7.5kw or as required

JF125-G

Nominal Pressure kn 1250

Slider Stroke mm 20

Perforating Speed times/min 120-140

Feeding Width mm ≤1250

Engine Power kw 18KW-4 or as required

JMC-160

Slider Stroke mm 30

Perforating Speed times/min 200

Feeding Width mm ≤1500

Engine Power kw 18.5 or as required

JMC-160 High Speed

Slider Stroke mm 30

Perforating Speed times/min 200

Feeding Width mm ≤1500

Engine Power kw 30kw-6 or as required

JF200-G

Nominal Pressure kn 2000

Slider Stroke mm 30

Perforating Speed times/min 100-200

Feeding Width mm ≤1500

Engine Power kw 30KW-6 or as required

D-250THigh Speed

Nominal Pressure kn 2500

Slider Stroke mm 30

Perforating Speed times/min 100-200

Feeding Width mm ≤1600

Engine Power kw 37-6

1. Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine. It can produce more than 6 kinds of panels.

2. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.

3. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

4. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't repair,we can send the new parts replace the broken parts freell,but you need pay the express cost yourself.if after warranty period,we can through negotiationfor to solve the problems,and we supply the technical support for the whole life of the equipment.

5. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich experience in transport.

6. You are trade company or factory?

We are trade company but we also have own factories. Building trade company is just for exporting various types of cold roll forming machines.

7. Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend time and money on developing How to make machines much more automatic, accurate and high quality. We can make sure thatour machine could use more than 20 years without any problem. We can provide 2 years free qualityassurance.

8. How long the machine could be made?

Normally speaking, welded pipe making machine could be made without 45 working days. If you need machines in a hurry, we can make it for you less than a month.

-

Steel pipe hole square punching hydraulic pipe punching machine

-

Manual license plate embossing machine hand embossing equipment M2/Jiehui

-

APEC punching die-cutting die punching round hole, oval hole

-

Thread punching machine (manufacturer)

-

High Quality Curtain Eyelet Machine Garment DIY Hand Press Riveter Machine

-

0.5T-1.5T force manual operation hand press for cutting bending punching riveting

-

Customized 10-160 tons C-type open-arm punch power press.

-

Automatic eyelet machine/automatic buttonhole machine/automatic eyelet punching machine

-

Wholesale Hand Corn Press Machine For Corn Tools Snap Rivet Corn Hand Press Maquina De Prensa De Ojales

-

Automatic buttonhole press machine flag button making machine flag hole making

Other Products

-

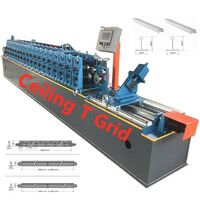

$70000.00 - $85000.00 / set

$70000.00 - $85000.00 / set -

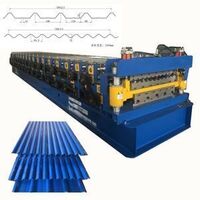

$20000.00 / set

$20000.00 / set -

$5000.00 / set

$5000.00 / set -

$15000.00 - $23000.00 / set

$15000.00 - $23000.00 / set -

$27800.00 - $29800.00 / set

$27800.00 - $29800.00 / set -

$20000.00 / set

$20000.00 / set -

$24000.00 / set

$24000.00 / set -

$14000.00 / set

$14000.00 / set -

$10000.00 / set

$10000.00 / set -

$38000.00 / set

$38000.00 / set