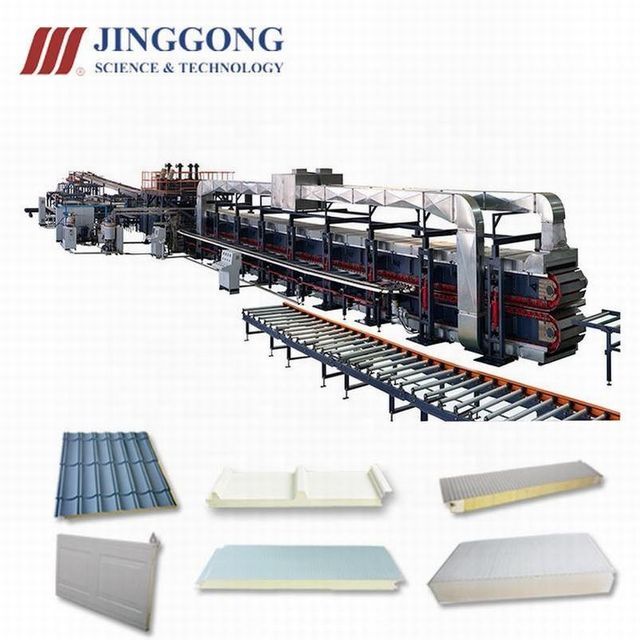

Building materials manufacturing machinery PU sandwich panel machine

-

Supplier: Zhejiang Jinggong Science & Technology Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Yan Wang -

Price: $500000.00 /set -

Min. Order: 1 set

Product details

| Certification: | Chief Executive; International Organization for Standardization | Applicable industries: | manufacturing plant |

| Production speed: | adjustable | Name: | PU sandwich panel production line |

| width: | up to 1250 mm | Warranty: | 1 year |

| Minimum order quantity: | 1 | Supply capacity: | 100 sets per month |

| strength: | about 300 | port: | Shanghai; Ningbo |

| After-sales service provided: | Engineers can repair machinery overseas | Packaging Details: | 1. Export standard container 2. Bare packaging. |

| brand: | Refined | place of origin; place of origin: | Zhejiang, China |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram | Mechanical test report: | if |

| thickness: | 0.4-0.8 | Core components: | consult us |

| Core Components Warranty: | 1 year | Weight (kg): | 6000 |

| Video external inspection: | if | color: | Everything is at your request |

| Material: | color steel plate; galvanized plate; aluminum plate | Showroom location: | not any |

| Marketing Type: | Hot Products of 2019 |

Product parameters

Do not. | thing | unit | scope | Comment | ||

1 | Applicable panel materials | type | Color-coated steel plate, aluminum plate, filler | According to customer requirements | ||

sheet strength | MPa | ≤350 | ||||

plate thickness | mm | 0.4-0.8 | ||||

board width | mm | ≤1250 (max) | According to panel shape | |||

Coil inner diameter | mm | 500,600 | ||||

Coil weight | Ton | 5,8 or 10 | optional | |||

2 | suitable core material | Rock wool, polyurethane, PIR | According to customer requirements | |||

3 | Panel length | Meter | 3-15 | |||

4 | panel width | mm | ≤1050 | According to panel shape | ||

5 | Panel thickness | mm | ≤200 | According to panel shape | ||

6 | Speed of work | m/min | 3-7 (adjustable) | adjustable | ||

7 | Foaming working pressure | bar | 150-200 | |||

8 | Double belt length | Meter | twenty one | |||

9 | Electronic control system | IPC PCL frequency conversion speed regulation | According to design requirements | |||

10 | total power | kilowatt | about 300 | |||

11 | Dimensions (LXWXH) | Meter | 110*15*5 | |||

detailed picture

JF 100 type PU sandwich panel production line is Automatic production line,It consists of uncoiler, laminating machine, pre-cutting equipment, forming machine system, preheating,blister, solidified,Band saw cutting,cool down, stacking and packaging.The whole line integrates mechanical, chemical, electronic control, hydraulic pneumatic, and temperature control technologies.

feature

1. Beautiful and practical,A variety of functions, such as thermal insulation, sound insulation and flame retardant.

2. Use Hot air circulation oven, Strictly control the PU foam curing temperature within the appropriate range.

3. Use High pressure foaming system, accurate measurement, high stability, less dust on site, and protect workers' health.

4. Use141B or C5 as foaming agent. Add CFC to make PU foaming treatment environmentally friendly

Production Process.

5. SpecialDouble belt conveyor, The surface of the sandwich panel is smooth, the thickness is uniform, and the anti-pattern n.

6. Operating system controlPLC computer, Humanized design, easy to operate.

1. Beautiful and practical,A variety of functions, such as thermal insulation, sound insulation and flame retardant.

2. Use Hot air circulation oven, Strictly control the PU foam curing temperature within the appropriate range.

3. Use High pressure foaming system, accurate measurement, high stability, less dust on site, and protect workers' health.

4. Use141B or C5 as foaming agent. Add CFC to make PU foaming treatment environmentally friendly

Production Process.

5. SpecialDouble belt conveyor, The surface of the sandwich panel is smooth, the thickness is uniform, and the anti-pattern n.

6. Operating system controlPLC computer, Humanized design, easy to operate.

Manufacturing Technology

panel type

Recommended Products

VIEW MORE

You may like

-

CANMAX Manufacturer Construction Engineering High Quality 12m Manual Electric Concrete Pump Spare Parts Mobile Concrete Spreading Arm

-

Prefab Modular House Prefab Prefab House Equipment China 2021

-

China Manufacturer Manufacturing Machine Technology Production Line Guide Rail Telescopic Channel Roll Forming Machine Drawer Slide

-

Earthquake Resistant Precast Concrete House Making Machine, Structural House Equipment

-

160L 280L 350L Tilt Drum Concrete Mixer Mobile Mini Cement Mixer Price

-

Best Selling Roller Shutter Slat Forming Machine / Roller Shutter Door Making Machine

-

Washbasin Pedestal Bathroom Casting Battery Stand

-

modern concrete house machines, fully prefab concrete houses

-

Price of machine for forming rolls of production line of continuous polyurethane sandwich panels factory customized with ISO9001 / Ce / Sonc

-

automatic steel t bar forming machine, ceiling system t grid making machine

Other Products

-

$150000.00 / set

$150000.00 / set -

$700000.00 / set

$700000.00 / set -

$150000.00 / set

$150000.00 / set -

$150000.00 / set

$150000.00 / set -

$150000.00 / set

$150000.00 / set

Related Search

sandwich panel machine

eps sandwich panel machine

metal pu sandwich panel

pu sandwich panel production line automatic

pu facade panel machine

Building Material Making Machinery Parts

sandwich manufacturing machinery

building material machinery

aluminum building material machine

building material machinery tile making