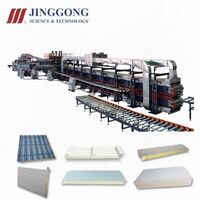

Price of machine for forming rolls of production line of continuous polyurethane sandwich panels factory customized with ISO9001 / Ce / Sonc

-

Supplier: Hebei Xinnuo Roll Forming Machine Co., Ltd. -

Region: Hebei, China -

Contact: Ms linda Li -

Price: $50000.00 / 1 - 1 sets

$45000.00 / 2 - 2 sets

$40000.00 / >=3 sets -

Min. Order: 1 set

| place of origin; place of origin: | Hebei china | Applicable industries: | Building materials stores, manufacturing plants, construction projects |

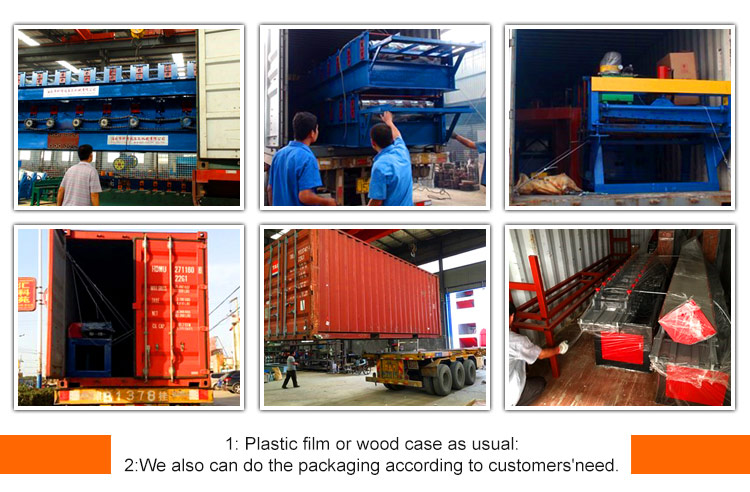

| After-sales service provided: | Engineers can go overseas to service machinery, online support, free spare parts, on-site installation, commissioning and training, on-site maintenance and repair services, video technical support | Packaging Details: | 6m/min Automatic EPS or Rock Wool Sandwich Panel Machine Thermal Insulation Composite Panel Making Machine Production Line The drum is packed in plastic film, and the machine is naked in a container |

| Core Components Warranty: | 1 year | Roller diameter of roll forming part: | 80mm |

| Main frame of sheet forming machine: | 300mm H-beam | Mechanical test report: | if |

| Formwork back plate thickness: | 20mm | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,cash |

| Video external inspection: | if | Chain Size: | 20mm |

| Warranty: | 20 months, 1 year | product name: | Sandwich panel machine production line / eps pu sandwich panel machine |

| Core Thickness: | 20-300mm | Total power: | 30kW |

| Local service location: | not any | Feed plate thickness: | 0.3-0.8mm |

| Supply capacity: | 10 eps pu sandwich panel machines per month | Core components: | alarm lock |

| port: | Tianjin harbor | brand: | Xinnuo |

| Showroom location: | not any | After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services |

| Marketing Type: | New Products 2020 |

Factory Customized Continuous PU Polyurethanesandwich control panelproduction lineroll forming machineISO9001/Ce/SGS/Soncap price

The main parameters

Customized according to customer requirements

|

Do not. |

Main parameters of sandwich panel forming machine production line |

||

|

1 |

suitable for processing |

Color steel plate |

|

|

2 |

board width |

1000&1200mm |

|

|

3 |

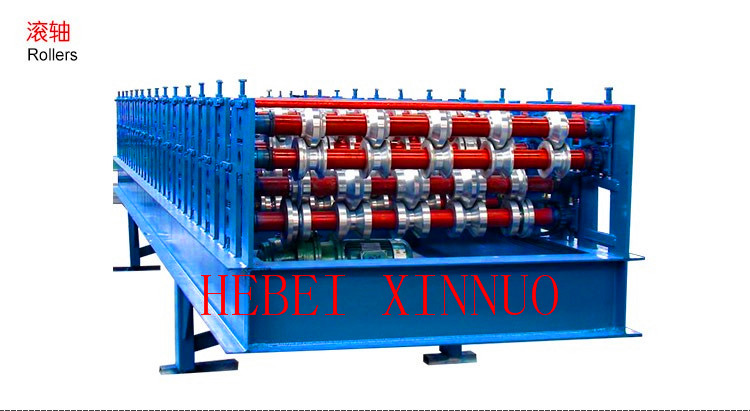

roller |

Lines 17-44 |

|

|

4 |

aspect |

38.0*2.25*2.5m |

|

|

5 |

strength |

30kW |

|

|

6 |

plate thickness |

0.3-0.8mm |

|

|

7 |

productivity |

6m/min |

|

|

8 |

Drum diameter |

Φ90mm |

|

|

9 |

weight |

about 15 tons |

|

|

10 |

Voltage |

380V 50Hz three-phase |

|

|

11 |

Cutting board material |

Cr12 |

|

|

12 |

Precision |

Within 1.00mm |

|

|

13 |

Control System |

PLC control |

|

technical parameter

|

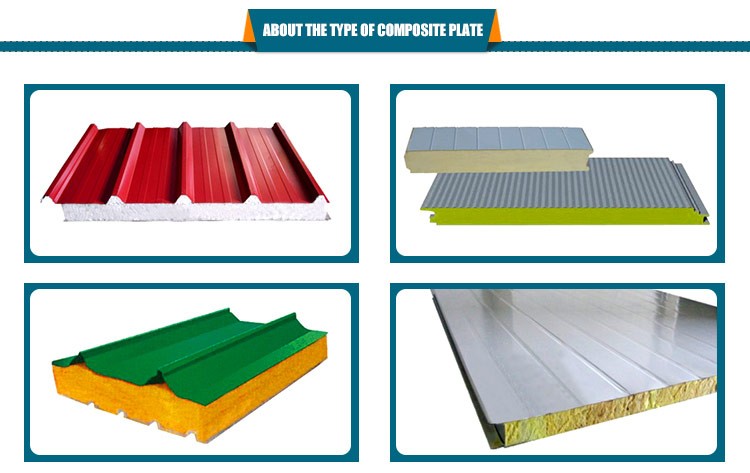

Sandwich Panel Standard |

|

|

length |

Minimum cutting length: 3 m |

|

Raw material standard |

|

|

Coil thickness |

0.4~0.6mm (the coil surface should be flat, No arches and other surface troubles. ) |

|

Material coil yield strength |

235MPa |

|

Maximum roll width |

See detailed outline drawing. |

|

Maximum roll weight |

5 tons |

|

Inner diameter of roll |

Φ508, Φ610mm |

|

EPS core material |

|

|

density |

≥18Kg/m3 |

|

direct rate |

≤1mm/m |

|

camber |

≤3mm/m |

|

panel surface |

should be flat No flatness ≤1.5mm/m, |

|

Sandwich panel length |

over 5 meters |

|

wool material |

|

|

Fiber length |

≥100mm |

|

Bulk density |

≥100Kg/m3 |

|

Sandwich panel length |

≥3 meters |

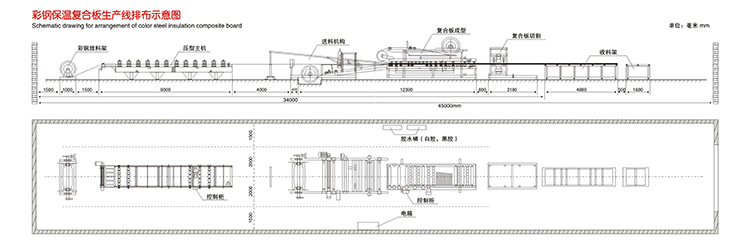

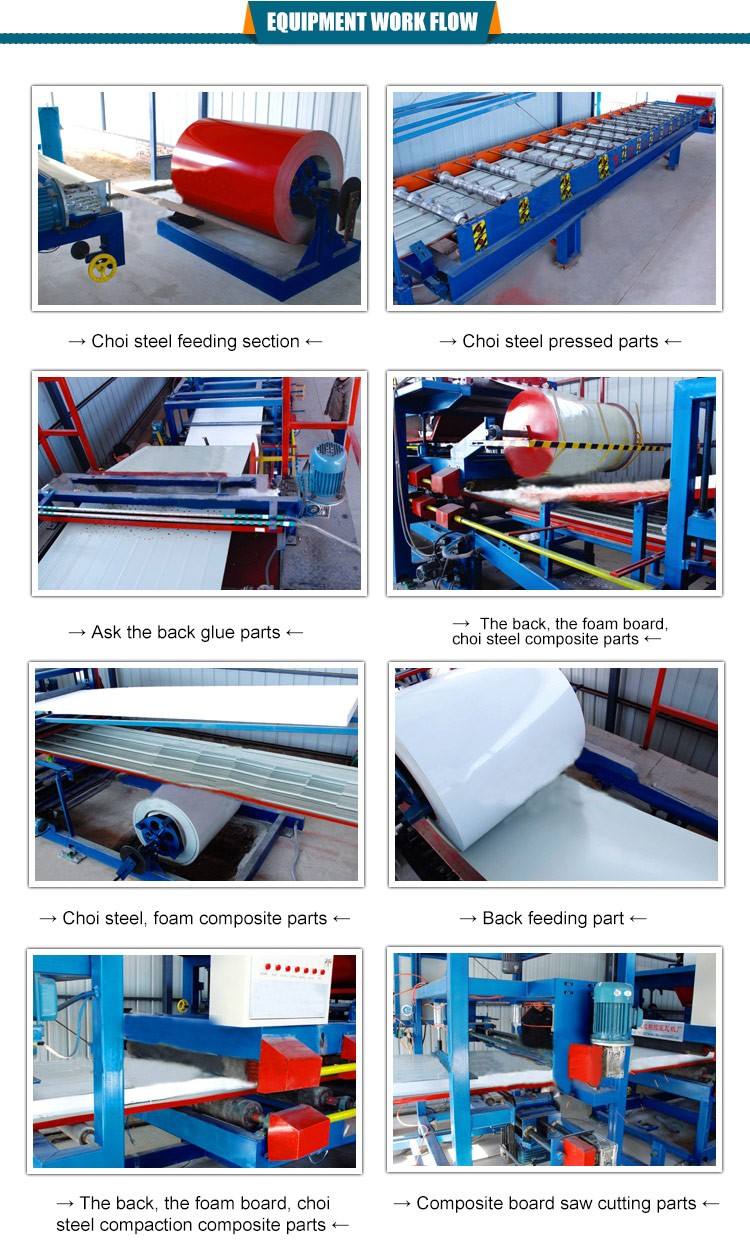

2. Process Technology and Deployment

Process: Composite uncoiler - Roll forming - Composite system (webbing, gelatinization, heating, composite, crimping, grooving, trimming) - Cutting system - Beating table

-

CANMAX Manufacturer Construction Engineering High Quality 12m Manual Electric Concrete Pump Spare Parts Mobile Concrete Spreading Arm

-

Prefab Modular House Prefab Prefab House Equipment China 2021

-

China Manufacturer Manufacturing Machine Technology Production Line Guide Rail Telescopic Channel Roll Forming Machine Drawer Slide

-

Earthquake Resistant Precast Concrete House Making Machine, Structural House Equipment

-

160L 280L 350L Tilt Drum Concrete Mixer Mobile Mini Cement Mixer Price

-

Best Selling Roller Shutter Slat Forming Machine / Roller Shutter Door Making Machine

-

Washbasin Pedestal Bathroom Casting Battery Stand

-

modern concrete house machines, fully prefab concrete houses

-

Building materials manufacturing machinery PU sandwich panel machine

-

automatic steel t bar forming machine, ceiling system t grid making machine

Other Products

-

$9000.00 - $22000.00 / set

$9000.00 - $22000.00 / set -

$58000.00 - $65000.00 / set

$58000.00 - $65000.00 / set -

$30000.00 / set

$30000.00 / set -

$42000.00 / set

$42000.00 / set