Gold ore cyanide leaching plant gold ore concentrator

-

Supplier: Zhengzhou Huahong Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr hong hua -

Price: $2000.00 /set -

Min. Order: 1 set

| Warranty: | one year | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| type: | Mine concentrator | Certification: | ISO9001 |

| Showroom location: | not any | Weight (kg): | 2200 |

| Core component warranty: | 1 year | Dimensions (L*W*H): | custom made |

| Video outbound inspection: | if | Mechanical test report: | if |

| After-sales service provided: | Engineers available to repair machinery overseas | color: | blue green |

| Supply capacity: | 180 sets per month | Core components: | Gearboxes, motors, gears |

| Origin: | Henan, China | Applicable industries: | Energy and Mining |

| Marketing Type: | normal product | Health status: | new |

| port: | Tianjin, Qingdao, Shanghai | Packaging Details: | no package |

| application: | Tailings dehydration | Production capacity: | 5.6 tons/day |

| brand: | Hua Hong | Motor type: | AC motor |

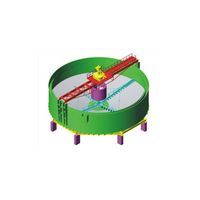

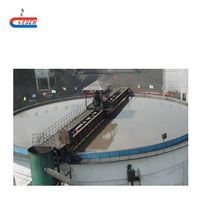

Efficient concentrator:

It is suitable for thickener concentrate and tailings dehydration, widely used in metallurgy, chemical industry, coal, non-metallic mineral processing, environmental protection and other industries. Our company's high-efficiency concentrator is suitable for dehydration of concentrated water and gangue during the concentration process. The factory can raise the mud from 20-30% to about 40-70%. The high-efficiency thickener sedimentation is actually not a simple device, but a new type of dehydration device combined with the filter function of the mud layer.

Working principle of high-efficiency concentrator:

Thickeners (high-efficiency thickeners) generally mainly include thickening tanks, DCB racks, transmission devices, DCB rack lifting devices, feeding devices, discharging devices, and signal safety devices. The main feature of the thickener (high-efficiency thickener) is that it is necessary to add a certain amount of flocculant to the pulp to make the ore in the pulp form flocculation particles, speed up its settling speed, and thus improve the enrichment efficiency.

Efficient concentratorfFeatures:

1. Add flocculants to increase the diameter of deposited solid particles and accelerate deposition.

2. Set the inclined plate to reduce the paste deposition distance and increase the deposition area.

3. It has flocculation effect. Percolation, compression and throughput of slurry deposits

4. Equipped with perfect automation facilities.

Technical data

|

Model

|

Concentration pool (m)

|

Side area (m2)

|

mention rake

|

engine

|

Capacity (t/d)

|

Weight (tons)

|

|||||

|

Model

|

number

|

diameter

|

depth

|

the bottom of the pool

|

model

|

Height (m)

|

Speed (min/rev)

|

spread

|

lift

|

||

|

NZS-1

|

Φ1.8m

|

1.8

|

1.8

|

2.54

|

hand

|

0.16

|

2

|

Y90L-6 1.1KW

|

---- |

5.6

|

1.235

|

|

NZS-3

|

Φ3.6m

|

3.6

|

1.8

|

10.2

|

hand

|

0.35

|

2.5

|

Y90L-6 1.1KW

|

---- |

22.4

|

3.064

|

|

NZS-6

|

Φ6m

|

6

|

3

|

28.3

|

hand

|

0.2

|

3.7

|

Y90S-4 1.1KW

|

---- |

62

|

8.751

|

|

NZSF-6

|

Φ6m

|

6

|

3

|

28.3

|

hand

|

3.7

|

Y90S-4 1.1KW

|

---- |

62

|

3.649

|

|

|

NZ-9

|

Φ9m

|

9

|

3

|

63.6

|

car

|

0.25

|

4.34

|

Y132S-6 3KW

|

XWD0.8-3 0.8KW

|

140

|

6.134

|

|

NZS-9

|

Φ9m

|

9

|

3

|

63.6

|

hand

|

0.25

|

4.34

|

Y132S-6 3KW

|

---- |

140

|

5.146

|

|

NZS-12

|

Φ12m

|

12

|

3.5

|

113

|

hand

|

0.25

|

5.28

|

Y132S-6 3KW

|

---- |

250

|

8.51

|

|

NZ-15

|

Φ15m

|

15

|

4.4

|

176

|

car

|

0.4

|

10.4

|

JTC752A-44 5.2KW

|

Y112M-6 2.2KW

|

350

|

21.757

|

|

NZ-20

|

Φ20m

|

20

|

4.4

|

314

|

car

|

0.4

|

10.4

|

JTC752A-44 5.2KW

|

Y112M-6 2.2KW

|

960

|

24.504

|

|

NZ-30

|

Φ30m

|

30

|

7.165

|

707

|

----

|

0.61

|

13.7

|

Y100L1-4 2.2×2KW

|

YCJ132-S 1.5KW

|

---- |

31.8

|

|

NZS-45

|

Φ45m

|

45

|

4.636

|

1590

|

hand

|

----

|

20

|

JTC672A-44 5.2KW

|

YCJ160-S 2.2KW

|

515

|

47.81

|

|

NT-15

|

Φ15m

|

15

|

3.5

|

177

|

---- |

---- |

8.4

|

Y132M2-6 5.5KW

|

----

|

390

|

11

|

|

NQ-18

|

Φ18m

|

18

|

3.5

|

255

|

---- |

---- |

10

|

Y132M2-6 5.5KW

|

----

|

Chapter 560

|

10

|

|

NQ-24

|

Φ24m

|

twenty four

|

3.4

|

Chapter 452

|

---- |

---- |

12.7

|

Y160M-6 7.5KW

|

----

|

1000

|

23.3

|

|

NG-30

|

Φ30m

|

30

|

3.6

|

707

|

---- |

---- |

16

|

Y160M-6 7.5KW

|

----

|

Chapter 1570

|

26.42

|

|

New Jersey-38

|

Φ38m

|

38

|

4.9

|

1134

|

---- |

---- |

10-25 days

|

JZT252-4 11KW

|

Y160M-6 7.5KW

|

1600

|

55.26

|

|

NT-45

|

Φ45m

|

45

|

5.05

|

1590

|

car |

---- |

19.3

|

Y160L-6 11KW

|

----

|

2400

|

58.64

|

|

NTJ-53

|

Φ53m

|

53

|

5.07

|

2202

|

----

|

----

|

23.18

|

Y180L-6-15kw

|

----

|

6250

|

79.80

|

|

NT-100

|

Φ100m

|

100

|

5.65

|

7846

|

----

|

----

|

43

|

Y180L-6 15KW

|

----

|

3030

|

199

|

Pictures of our little models:

-

Low cost mud water sludge thickener liquid thickener

-

Hua Center Transmission Concentrate Tailings Thickener Dehydration

-

Ex-factory price copper-iron-lithium ore sedimentation tank sludge thickener

-

Fully automatic mine tailings concentrate treatment mud sewage sludge dehydration high-efficiency thickener price

-

Sludge Collector Circular Settling Thickener Tank Sludge Scraper Peripheral Drive Sludge Classifier Thickener Price For Sale

-

Factory price sedimentation tank NZS-3 slime thickener for sale

-

Tailings gold beneficiation high-efficiency thickener

-

mine iron ore dewatering thickener/slurry sludge thickener tank sedimentation tank

-

Low Price Sludge Thickening Tank Supplier

-

Circular concentration clarifier gravity concentration tank

Other Products

-

$20000.00 / set

$20000.00 / set -

$2900.00 - $3000.00 / set

$2900.00 - $3000.00 / set -

$12000.00 - $55000.00 / set

$12000.00 - $55000.00 / set -

$1000.00 / set

$1000.00 / set -

$1000.00 - $3200.00 / set

$1000.00 - $3200.00 / set -

$2900.00 - $3000.00 / set

$2900.00 - $3000.00 / set -

$6900.00 - $7000.00 / set

$6900.00 - $7000.00 / set -

$3800.00 - $4000.00 / set

$3800.00 - $4000.00 / set -

$4000.00 / set

$4000.00 / set -

$1000.00 / set

$1000.00 / set