Tailings gold beneficiation high-efficiency thickener

-

Supplier: Gongyi City Yuxiang Heavy Machinery Co., Ltd. -

Region: Henan, China -

Contact: Mr Jack Chen -

Price: $3000.00 / 1 - 4 sets

$2500.00 / >=5 sets -

Min. Order: 1 set

Product details

| Warranty: | 1 year | product name: | thickener |

| Core component warranty: | 1 year | International Organization for Standardization: | ISO 9001 |

| Material: | Carbon steel | Mining Thickener Price: | negotiable |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | application: | ore |

| Applicable industries: | Energy and Mining | Mechanical test report: | if |

| Dimensions (L*W*H): | depends on model | Origin: | Henan, China |

| aspect: | 6520*5620*4100 | Key words: | thickener |

| Video shipment inspection: | if | Supply capacity: | 100 sets per month |

| brand: | Yu Xiang | usage: | mineral tailings thickener |

| capacity: | 5-1400 tons/day | Showroom location: | not any |

| Weight (kg): | 10000 | Core components: | engine |

| Other names: | mining thickener | port: | Qingdao, Tianjin |

| Health status: | new | Packaging Details: | High Efficiency Pulp Thickener Machine For Gold Ore Thickening From Tailings Packaging Details: Standard Export Container Packaging Delivery Details: 1-5 days after order |

| After-sales service: | Engineers can repair machinery overseas and install on site | Motor type: | AC motor |

| Marketing Type: | New Products 2022 | type: | mining thickener |

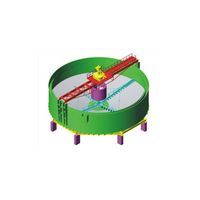

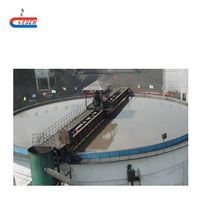

Tailings gold beneficiation high-efficiency thickener

Product Description

Thickening or dewatering can be defined as the removal of a portion of the liquid from a pulp or mucilage consisting of a mixture of finely divided solids and liquids. It is mainly used for concentrate concentration and tailings dehydration in mineral processing plants.

feature:

(1) Add flocculant to increase the particle size of settled solid particles, thereby accelerating the settling speed;

(2) Install inclined plates to shorten the settlement distance of ore particles and increase the settlement area;

(3) Play the role of flocculation, filtration and compression, and improve the processing capacity of the dense layer of sediment;

(4) Equipped with perfect automatic control facilities.

Specification

Specification | Concentrator | Sedimentation area (m2) | Rake speed(r/min) | engine | capacity (t/day) | ||||

Specification | diameter (rice) | Depth (m) | Model | strength | capacity tons/day) | ||||

NZS1 | 1.8 | 1.8 | 2.55 | 0.5 | Y9CL-6 | 1.1 | 1.3-5.6 | ||

NZS2.5 | 2.5 | 1.8 | 4.9 | 0.33 | Y9CL-6 | 1.1 | 5-10.8 | ||

NZS3 | 3.6 | 1.8 | 10.2 | 0.33 | Y9CL-6 | 1.1 | 5-22.4 | ||

NZS6 | 6 | 2.95 | 28 | 0.3 | Y9CL-4 | 1.5 | 14-62 | ||

NZS8 | 8 | 3.318 | 50.2 | 0.27 | Y132S-6 | 3 | |||

NZS9 | 9 | 3 | 63.5 | 0.25 | Y132S-6 | 3 | 32-150 | ||

NZS12 | 12 | 3.6 | 113 | 0.19 | Y132S-6 | 3 | 250 | ||

NZSG-2.5 | 2.5 | 1.85 | 4.9 | Y9CL-6 | 1.1 | 5-22.4 | |||

NZSG-3A | 3 | 1.8 | 7 | Y100L-6 | 1.5 | 5-23.4 | |||

NZSG-3 | 3.6 | 1.8 | 10.2 | Y100L-6 | 1.5 | 5-25 | |||

NZSG-5 | 5 | 2.956 | 16 | Y9CL-4 | 1.5 | 16-90 | |||

NZSG-6 | 6 | 2.956 | 28.3 | Y9CL-4 | 1.5 | 98 | |||

NZSG-7 | 7 | 3 | 38.5 | Y112M-6 | 2.2 | ||||

NZSG-8 | 8 | 3.318 | 50.2 | Y132S-6 | 3 | ||||

NZSG-9 | 9 | 3.376 | 63 | Y132S-6 | 3 | 210 | |||

NZSG-12 | 12 | 3.6 | 113 | Y132S-6 | 3 | 370 | |||

NZSG-15 | 15 | 3.6 | 176 | Y132M2-6 | 5.5 | 580 | |||

NZSG-18 | 18 | 4.4 | 255 | YCT200-413 | 7.5 | 960 | |||

NZSG-20 | 20 | 4.4 | 315 | Y160M2-8 | 7.5 | 1400 | |||

application

Thickeners are important and widely used in mineral processing to prepare concentrates from ROM (raw ore). Specifically, the thickener is used to increase the solid content of the concentrate pulp (concentrate + process water), so that we can effectively transport the concentrated pulp and reuse the process water.

work rules

The thickener is mainly composed of a round thickening basin and a rake scraper. The solid particles suspended in the thickener fall down under the action of gravity, and the upper slurry becomes clear water, thereby realizing separation. The pulp deposited at the bottom of the thickening tank is continuously discharged to the center by the rake scraper, and the clean water overflows along the upper edge of the thickening tank.

Product Case

VIEW MORE

You may like

-

Low cost mud water sludge thickener liquid thickener

-

Hua Center Transmission Concentrate Tailings Thickener Dehydration

-

Ex-factory price copper-iron-lithium ore sedimentation tank sludge thickener

-

Fully automatic mine tailings concentrate treatment mud sewage sludge dehydration high-efficiency thickener price

-

Sludge Collector Circular Settling Thickener Tank Sludge Scraper Peripheral Drive Sludge Classifier Thickener Price For Sale

-

Gold ore cyanide leaching plant gold ore concentrator

-

Factory price sedimentation tank NZS-3 slime thickener for sale

-

mine iron ore dewatering thickener/slurry sludge thickener tank sedimentation tank

-

Low Price Sludge Thickening Tank Supplier

-

Circular concentration clarifier gravity concentration tank

Other Products

-

$5000.00 / set

$5000.00 / set -

$3600.00 / set

$3600.00 / set

Related Search

high efficiency sawdust dryer

high efficiency quilting sewing machine

high effici heat exchang suppliers

high effici granul suppliers

air cooled water with high efficiency and

high efficiency candle machine

high efficiency lime stone crusher

finger highly efficient

high efficiency gw40 bending machines

ghl series high efficiency wet mixing granulator