Low Price Sludge Thickening Tank Supplier

-

Supplier: Henan Xingyang Mining Machinery Manufactory -

Region: Henan, China -

Contact: Mr Andy Zhang -

Price: $5200.00 /set -

Min. Order: 1 set

| Dimensions (L*W*H): | Specification | Supply capacity: | 35 sets per month |

| product quality: | reliable | work process: | Designed by our engineers |

| State of health: | new | Packaging Details: | Seaworthy container or as your request |

| Marketing Type: | normal product | Package preview: | |

| Core component warranty: | 1 year | Company experience: | over 35 years |

| spare parts: | supplied by us | Recovery rate: | High |

| Mechanical test report: | if | brand: | Xinkaijian |

| payment terms: | L/C, T/T, Western Union | place of origin; place of origin: | Henan, China |

| Certification: | ISO9001:2008, EU certification | Production capacity: | More than 85% |

| Local service location: | Indonesia, Mexico, Australia, Morocco, Kenya, South Korea, Colombia, Romania, South Africa | Applicable industries: | Manufacturing plants, machinery repair shops, energy and mining |

| Warranty: | One year, except wearing parts | Showroom location: | not any |

| Types of: | mining thickener | Prompt delivery: | Appropriately |

| port: | Major ports such as Qingdao/Shanghai/Tianjin | Motor type: | AC motor |

| application: | Concentrate, tailings, dehydration, desliming, etc. | Service life: | over 3 years |

| After-sales service provided: | Engineers available to service machinery overseas | Manufacturing Standards: | Meets industry standards |

| Video shipment inspection: | if | Quality Control: | pass five levels |

| Core components: | Bearings, motors, pumps |

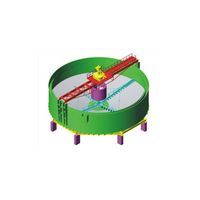

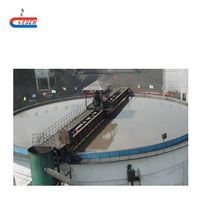

Concentrator product description:

thickenerIt is suitable for the dehydration of beneficiation water and coal gangue in mineral processing plants, increasing the 20-30% ore pulp to about 40-70%.ConcentratorWidely used in smelting, chemical industry, coal, non-metallic mineral processing, environmental protection, etc.

The concentrator is suitable for the dehydration of beneficiation water and coal gangue in mineral processing plants.

Concentrator features:

(1) Adding flocculent sediment increases the size of solid particles, thereby speeding up;

(2) Shorten the settlement distance of ore grains installed on the inclined plate and increase the settlement area;

(3) It can flocculate, filter, compress and treat the deposited layer of thick mud;

(4) Equipped with complete self-control facilities.

Applications:

Widely used in metallurgy, mining, coal, petrochemical, building materials, environmental protection and other departments to deal with coal slime, waste water, waste residue, etc.

Product principle:

The thickener is composed of a circular thickener and a rake scraper. The solid particles suspended in the thickener settle by gravity, and the upper layer of slurry turns into clean water to realize separation. The sediment at the bottom of the thickener is continuously scraped by rakes to remove the discharged mud, and it overflows cleanly from above.

Inspur Central Drive Thickener Parameters

|

Model |

Concentrator |

Depth of concentration tank (mm) |

deposited |

Wuhe speed(rpm) |

motor model |

Motor power (kw) |

Motor revolution(rpm) |

Capacity (t/d) |

W's |

W (Ton). |

|

NZS1 |

1800 |

1800 |

2.55 |

0.5 |

Y90L-6 |

1.1 |

910 |

1.3∼5.6 |

602 |

1300 |

|

NZS2.5 |

2500 |

1800 |

4.9 |

0.33 |

Y90L-6 |

1.1 |

910 |

5∼10.8 |

1730 |

2355 |

|

NZS3 |

3600 |

1800 |

10.2 |

0.33 |

Y100L-6 |

1.5 |

940 |

5∼22.4 |

1730 |

2975 |

|

NZS6 |

6000 |

2956 |

28.3 |

0.3 |

Y90L-4 |

1.5 |

1400 |

14~62 years old |

5690 |

8700 |

|

NZS8 |

8000 |

3318 |

50.2 |

0.27 |

Y132S-6 |

3 |

960 |

25∼120 |

11065 |

15460 |

|

NZS9 |

9000 |

3000 |

63.5 |

0.25 |

Y132S-6 |

3 |

960 |

32∼150 |

12188 |

16682 |

|

NZS12 |

12000 |

3600 |

113 |

0.19 |

Y132M2-6 |

3 |

960 |

50∼250 |

24060 |

33131 |

|

NZS15 |

15000 |

3600 |

177 |

0.1 |

Y132M2-6 |

5.5 |

960 |

70∼350 |

35296 |

55499 |

|

NZS18 |

18000 |

4400 |

268 |

0.1 |

Y132M2-6 |

5.5 |

960 |

100∼560 |

|

10139 |

|

NZD 20 |

20000 |

4400 |

314 |

0.1 |

Y132M2-6 |

5.5 |

960 |

200~1440 |

24500 |

-

Low cost mud water sludge thickener liquid thickener

-

Hua Center Transmission Concentrate Tailings Thickener Dehydration

-

Ex-factory price copper-iron-lithium ore sedimentation tank sludge thickener

-

Fully automatic mine tailings concentrate treatment mud sewage sludge dehydration high-efficiency thickener price

-

Sludge Collector Circular Settling Thickener Tank Sludge Scraper Peripheral Drive Sludge Classifier Thickener Price For Sale

-

Gold ore cyanide leaching plant gold ore concentrator

-

Factory price sedimentation tank NZS-3 slime thickener for sale

-

Tailings gold beneficiation high-efficiency thickener

-

mine iron ore dewatering thickener/slurry sludge thickener tank sedimentation tank

-

Circular concentration clarifier gravity concentration tank

Other Products

-

$699.90 / set

$699.90 / set -

$5850.00 / set

$5850.00 / set -

$2000.00 / set

$2000.00 / set -

$699.90 / set

$699.90 / set -

$5300.00 / set

$5300.00 / set -

$629.30 / set

$629.30 / set -

$900.00 - $930.00 / set

$900.00 - $930.00 / set -

$2500.00 / set

$2500.00 / set -

$6500.00 / set

$6500.00 / set -

$6200.00 / set

$6200.00 / set