Small capacity 10tph 20tph 25tph log washing machine, double helix log washing machine for sale

-

Supplier: Henan Xingyang Mining Machinery Manufactory -

Region: Henan, China -

Contact: Mr Andy Zhang -

Price: $2500.00 /set -

Min. Order: 1 set

| Dimensions (L*W*H): | custom made | port: | Qingdao or Tianjin |

| Warranty: | 12 months, excluding wearing parts | Motor Type: | AC motor |

| Packaging Details: | Export standard container 20GP or 40GP, 40HQ, FR container, bulk, spare parts in wooden case | Core Components Warranty: | 1 year |

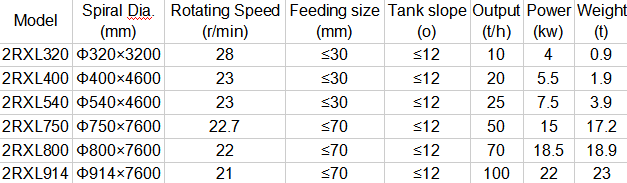

| Supply capacity: | 80 sets per month | Spiral Diameter: | 320-914mm |

| Capacity (tons/hour): | 10-100 | place of origin; place of origin: | Henan, China |

| Video external inspection: | if | application: | Mine washing, soil washing, sand washing, sand washing |

| Install: | under the guidance | Marketing Type: | normal product |

| Certificate: | ISO 9001:2008 | Health status: | new |

| quality: | reliable | After-sale service: | better one |

| Cushion: | iron plate | Certification: | ISO9001:2008/CE |

| brand: | New Kangjie | Rotating speed: | 21-28/r/min |

| payment terms: | letter of credit, wire transfer | Applicable industries: | Building Materials Stores, Manufacturing Plants, Food Stores, Construction Engineering, Energy & Mining |

| Core components: | Bearings, gearboxes, gears | Showroom location: | Pakistan, India, Thailand |

| weight: | 0.9kg | Mechanical test report: | if |

| delivery time: | timely |

Log washers are ideal for scrubbing difficult materials. Tough insoluble clays, conglomerates and soft stones, as well as certain cementitious aggregates, are difficult to clean properly in ordinary screw machines. The log washer thoroughly scours, breaks down and cleans the toughest materials. These high quality, highly durable machines perform well in the toughest clay conditions with minimal power, water and downtime.

Application of log cleaning machine:

iron ore

gravel

gravel

recycled material

Most bulk materials that require cleaning

| Advantages of wood washing machines | |

| 1 | Log washers are ideal for scrubbing difficult materials such as tough insoluble clays, conglomerates, soft stones and cemented aggregates |

| 2 | High capacity |

| 3 | Heavy delivery paddle |

| 4 | Made with heavy duty tubs |

| 5 | Oversized Bearings and Gears |

| 6 | Thick-walled shaft |

| 7 | The lower end is bolted to a fully machined stub shaft. The upper end is mounted on the output shaft of the gearbox through an elastic coupling |

| 8 | Compound drives distribute workload through an optimal combination of oversized helical and spur gears |

| 9 | Continuous grinding and grinding of log cleaning paddles |

| 10 | Adjustable drain doors on both sides of the lower end of the bathtub |

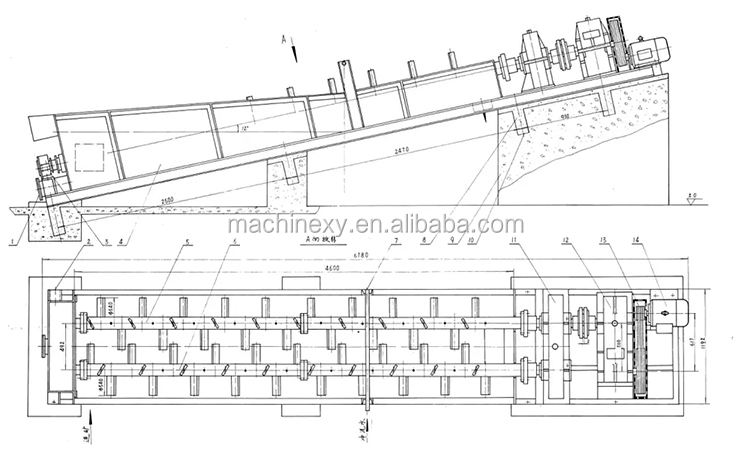

Working principle:The installation angle of the equipment is 10°~14°. During operation, the two axes of rotation in the groove rotate in opposite directions. The material enters the middle of the two rotating shafts from the inside of the tank about 1/3 from the overflow end. The coarse ore in the tank is repeatedly washed by the blades and sent to the front end for unloading, and then sprayed to discharge to reach the qualified ore.

The sediment washed from the ore flows out through the overflow weir behind the tank and becomes tailings. Rinse the ore with a water gun in advance for better washing results.

Before Service: Enthusiasm

1) We will reply your inquiry within 24 hours.

2) Our experienced staff will explain all your inquiries well.

Service during the sale: Servant

1) Pre-check and accept the product before delivery

2) The purchase contract has a certain credit guarantee to provide you with the perfect product in your hands.

After-sale service: integrity

1) Send technicians to the customer's local area to guide installation and debugging, and train operators.

2) In addition, our company provides a one-year warranty to ensure that the machine runs consistently.

If you are interested in our products,

Please contact us as soon as possible.

↓↓↓↓

-

Large-capacity double-screw sand washing machine double-screw sand washing machine

-

2022 mobile sand washing machine sand washing machine price aggregate stone sand washing machine

-

River sand silica gel sand washing machine spiral sand cleaning machine price

-

100 Tph Sand Washer Fine Material Washer Screw New 2 Years Warranty

-

LDHB 2LD36-100-2442J double-wheel wet silica sand washing and dehydration equipment

-

Shaking Table Fine Gold Recovery Equipment Genemi Mineral Separator

-

dry washer Gold mining dry washer

-

Large capacity professional new sand washing machine

-

Drum washing machine price sand washing factory for sale ore washing machine

-

Fine sand collection equipment sand recovery machine with wheeled sand washing machine

Other Products

-

$699.90 / set

$699.90 / set -

$5850.00 / set

$5850.00 / set -

$2000.00 / set

$2000.00 / set -

$699.90 / set

$699.90 / set -

$5300.00 / set

$5300.00 / set -

$629.30 / set

$629.30 / set -

$900.00 - $930.00 / set

$900.00 - $930.00 / set -

$5200.00 / set

$5200.00 / set -

$6500.00 / set

$6500.00 / set -

$6200.00 / set

$6200.00 / set