Mixing tank high-efficiency high-quality mixing tank / mineral mixer / mixing bucket

-

Supplier: Henan Xingyang Mining Machinery Manufactory -

Region: Henan, China -

Contact: Mr Andy Zhang -

Price: $699.90 /set -

Min. Order: 1 set

Product details

| price: | negotiate | Mechanical test report: | if |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Showroom location: | Turkey, Brazil, Pakistan, Argentina, Bangladesh, South Africa, Japan |

| Marketing Type: | Hot Products of 2021 | color: | customizable |

| Local service locations: | Italy, Philippines, India, Malaysia, Kenya, Romania, Kazakhstan, Ukraine | After-sales service provided: | Free spare parts, video technical support, on-site installation, commissioning and training, on-site maintenance and repair services |

| Supply capacity: | 30 groups per week | After-sales service: | 7*24 hours |

| Packaging Details: | packed in a log or a container | brand: | New Kejie |

| Certification: | Silicate, CE | Dimensions (L*W*H): | 1354x1310x1742 |

| Video outbound inspection: | if | type: | Leach tank |

| Core component warranty: | 1 year | Origin: | Henan, China |

| Core components: | Engine, gearbox, motor | Online Service Hours: | 24 hours online |

| Health status: | new | Effective volume (cubic meter): | 0.33-30 |

| Applicable industries: | Building material stores, construction works, energy and mining, advertising agencies | Spare parts supply: | Any time |

| Factory tour: | warm welcome | delivery time: | 15-30 days |

| diameter: | 50-3550 | port: | Qingdao, Shanghai, Tianjin |

| quality: | Advanced technology | Warranty: | 1 year |

| Motor type: | AC motor | Package preview: |

Product Description

mineral mixing bucket- Product Description

[introduce]:

The necessary equipment for the mineral mixing tank, the motor power triangle belt drives the impeller to rotate, fully mixes the medicine and the pulp evenly, increases the reaction time, and strengthens the effect of the reaction quality of the medicine and medicine. This machine is suitable for

It can be used in mineral processing and chemical industry as a mixing ingredient. It adopts a density of less than 30%, a frozen composition less than 1mm, forming a flat-bottomed barrel-shaped radiation, and a round cross-neck mechanical agitation.

It can be used in mineral processing and chemical industry as a mixing ingredient. It adopts a density of less than 30%, a frozen composition less than 1mm, forming a flat-bottomed barrel-shaped radiation, and a round cross-neck mechanical agitation.

Advantage

mineral mixing bucket-Advantage

1. The diameter of the impeller increases, and the peripheral speed of the impeller increases, which improves the stirring ability of pulp and chemicals.

2. The impeller is designed as mushroom cap type, which improves the stirring and circulation ability of pulp and chemicals. 3. Equipped with a duck, the impeller is located inside the duckbill. The improvement of the stirring capacity increases the negative pressure generated by the movement of the slurry, which is restricted in a limited space by the pipeline, which enhances the suction capacity of the slurry and chemicals, and further strengthens the circulation of the slurry and chemicals. 4. The cap impeller generates downward pressure during operation, which strengthens the suction force again, thereby enhancing the circulation of slurry and chemicals. 5. There is a nozzle under the air duct, which is also conducive to circulation. The sufficient agitation cycle of the pulp and the chemical agent makes the mineral surface fully contact with the chemical agent, which is beneficial to flotation. Only 100% of the mineral surface is in contact with the reagents, ensuring high recovery rates.

Product Details

product specification

standard model | XB-500 | XB-1000 | XB-1500 | XB-2000 | XB-2500 | XB-3000 | ||

Effective volume (m3) | 0.124 | 0.58 | 2.2 | 5.46 | 11.2 | 19.1 | ||

impeller | Diameter (mm) | 150 | 240 | 400 | 550 | 650 | 700 | |

Speed (rev/min) | 1000 | Chapter 530 | 320 | 230 | 280 | 210 | ||

engine | Model | Y100L-4 | Y132S-6 | 132M-6 | Y160M-6 | 180L-6 | Y225S-8 | |

Power (kW) | 1.5 | 3 | 5.5 | 7.5 | 15 | 18.5 | ||

Internal Tank size | Diameter (mm) | Φ500 | Φ1000 | Φ1500 | Φ2000 | Φ2500 | Φ3000 | |

Height (mm) | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | ||

length (mm) | 670 | 1130 | 1750 | 2380 | 3028 | 3610 | ||

Width (mm) | Chapter 351 | 1130 | Chapter 1642 | 2162 | 2640 | 3266 | ||

Height (mm) | 1286 | Chapter 1491 | 2186 | 2846 | 3543 | 4326 | ||

Weight (tons) | 0.375 | 0.685 | 1.2 | 1.65 | 3.462 | 4.292 | ||

work rules

mineral mixing bucketwork rules

The main structure of the wheel transmission device is composed of fixed rollers, movable rollers, transmission shafts, chassis, chassis, covers, long gear covers, etc. The power of the machine comes from the V-belt pulley of the electric motor and a pair of intermediate pulleys.

The reduction gear rotates the fixed roller, and then a pair of long gears on the other side of the fixed roller drive the movable roller, and the two rollers move relative to each other to squeeze the material..

The reduction gear rotates the fixed roller, and then a pair of long gears on the other side of the fixed roller drive the movable roller, and the two rollers move relative to each other to squeeze the material..

VIEW MORE

You may like

-

Gold Mining Leaching Tank/CIL Small Gold Processing Plant Mixing Tank

-

Mineral mud mixing tank Mixing tank Mineral mixing barrel

-

XB-1000 gold stirring leaching tank

-

Mixed leaching tank / gold ore stirring leaching tank

-

High-efficiency beneficiation mixing mixing tank gold ore tailings leaching processing plant mixing mixing tank with agitator

-

High quality mining equipment double impeller leaching mixing tank for gold mine

-

Energy-saving gold stirring leaching tank

-

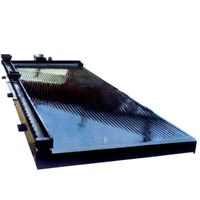

High quality vibrating table top of 6S vibrating table for gold ore separation

-

High-quality mining barreled equipment gold leaching mixing tank

-

African hot selling gold ore process line mine mixer chemical stirring leaching tank

Other Products

-

$699.90 / set

$699.90 / set -

$5850.00 / set

$5850.00 / set -

$2000.00 / set

$2000.00 / set -

$5300.00 / set

$5300.00 / set -

$629.30 / set

$629.30 / set -

$900.00 - $930.00 / set

$900.00 - $930.00 / set -

$5200.00 / set

$5200.00 / set -

$2500.00 / set

$2500.00 / set -

$6500.00 / set

$6500.00 / set -

$6200.00 / set

$6200.00 / set

Related Search

high quality milk tank

high quality auto parts

high quality industrial dehumidifiers

high quality baby wet wipes

elephant chain hoist with high quality

pallet packing pp strapping high quality

high quality cooling tower types

high quality inkjet printer cartridge

high quality toilet soap machine

high quality sublimation transfer paper