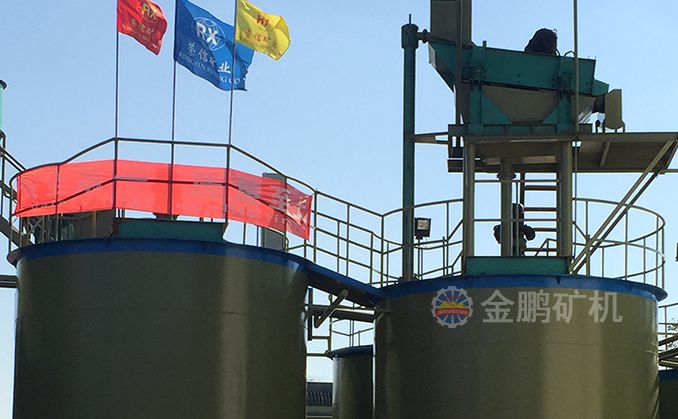

High quality mining equipment double impeller leaching mixing tank for gold mine

-

Supplier: Yantai Jinpeng Mining Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Ms Bella Wang -

Price: $110000.00 /set -

Min. Order: 1 set

Product details

| Applicable industries: | Energy and Mining | Core component warranty: | 1 year |

| State of health: | new | Core components: | engine, motor |

| After-sales service provided: | Engineers available to service machinery overseas | Motor type: | AC motor |

| place of origin; place of origin: | Shandong China | Packaging Details: | export standard packaging |

| port: | Qingdao Yantai Dalian | color: | customizable |

| Video shipment inspection: | if | Mechanical test report: | if |

| payment terms: | L/C, T/T | Production capacity: | 99% |

| Dimensions (L*W*H): | to see | Marketing Type: | New Products 2022 |

| quality: | Advanced technology | application: | mining |

| price: | Negotiable | brand: | Jinpeng |

| market: | Worldwide | usage: | Leaching equipment |

| Install: | Technical support | Types of: | Leach tank |

| Supply capacity: | 50 sets per week | Weight (kg): | 1000 |

| Showroom location: | Indonesia, Chile | Warranty: | 1 year |

Product Description

Double impeller leaching mixing tank

Compared with the ordinary mixing tank, the double-impeller leaching mixing tank adopts double impellers, and the pulp is stirred evenly

The more even it is, the more energy-efficient it is in terms of energy consumption. The impeller adopts the rubber-covering process, which has a long service life, is convenient to use for air supply, and has uniform air and gas.

The more even it is, the more energy-efficient it is in terms of energy consumption. The impeller adopts the rubber-covering process, which has a long service life, is convenient to use for air supply, and has uniform air and gas.

Effective volume: 6-1740m³

work rules

scope of application

Small specific gravity, low viscosity, slow settling speed, ore particle size within 200 yards accounts for more than 90%, pulp density is less than 45%, gold leaching, adsorption, etc. are mixed.How the product works

Under the agitation of double impellers, under the action of resistance, the pulp flows from top to bottom in the center and spreads

The damping plate, through which air is passed at the lower end of the shaft, mixes with the slurry and circulates upwards to form a uniform suspension mixture.

Advantage

Features of double leaf leaching mixing tank:

1. Ventilation is to use the tube or hollow shaft that surrounds the bottom with air to ventilate, so that the air enters the mixing tank through the air tube or hollow shaft, and the gas is evenly dispersed and the bubbles are small.

2. The new type of large-diameter rubber impeller is adopted, with low speed and long service life.

3. There is a very strict control on the stirring intensity, so that the concentration and fineness distribution in the stirring tank are consistent. Improve cyanide in and out rate and carbon adsorption rate.

The company optimizes and improves the structure of the pneumatic system, gas lift system, and carbon-carbon separation system. The ore flow is stable, the slurry is mixed, and the power consumption is small, thereby reducing the wear of carbon. Compact structure and easy maintenance. The specifications of the leaching tank with a maximum diameter of more than 10 meters have been developed, and the structure and performance are also continuously improved.

1. Ventilation is to use the tube or hollow shaft that surrounds the bottom with air to ventilate, so that the air enters the mixing tank through the air tube or hollow shaft, and the gas is evenly dispersed and the bubbles are small.

2. The new type of large-diameter rubber impeller is adopted, with low speed and long service life.

3. There is a very strict control on the stirring intensity, so that the concentration and fineness distribution in the stirring tank are consistent. Improve cyanide in and out rate and carbon adsorption rate.

The company optimizes and improves the structure of the pneumatic system, gas lift system, and carbon-carbon separation system. The ore flow is stable, the slurry is mixed, and the power consumption is small, thereby reducing the wear of carbon. Compact structure and easy maintenance. The specifications of the leaching tank with a maximum diameter of more than 10 meters have been developed, and the structure and performance are also continuously improved.

Product parameters

Model | Tank specification (mm) length x length | Effective volume (m³) | impeller speed (revolutions per minute) | impeller diameter (mm) | engine Model | engine strength (kilowatt) | tank weight (Kilogram) | Total weight (kg) |

SJ2.0×2.5 | 2000×2500 | 6 | 52 | 909 | XLD2.2-4-29 | 2.2 | 2144 | |

SJ2.5×3.15 | 2500×3150 | 13.14 | 52 | 935 | XLD2.2-4-29 | 2.2 | 2242 | 3095 |

SJ3.0×3.0 | 3000×3000 | 18 | 40.85 | 1130 | XLD4-5-35 | 4 | 2802 | 4161 |

SJ3×3.15 | 3000×3150 | 18.93 | 43 | 1130 | XLD4-5-35 | 4 | 3331 | 4323 |

SJ3.15×3.55 | 3150×3550 | twenty four | 43 | 1260 | XLD4-5-35 | 4 | 3391 | 4583 |

SJ3.5×3.5 | 3500×3500 | 30 | 52 | 1310 | XLD5.5-5-29 | 5.5 | 4286 | 5025 |

SJ3.5×4.0 | 3500×4000 | 32.7 | 41 | 1310 | XLD5.5-5-29 | 5.5 | 4631 | 5429 |

SJ3.55×4.0 | 3550×4000 | 33.6 | 43 | 1310 | XLD4-5-35 | 4 | 4860 | 5825 |

SJ3.7×4.2 | 3700×4200 | 38.4 | 42 | 1310 | XLD4-5-35 | 4 | 5058 | 6153 |

SJ4.0×4.0 | 4000×4000 | 38 | 35 | 1750 | XLD7.5-7-43 | 7.5 | 6056 | 7450 |

SJ4.0×4.5 | 4000×4500 | 48 | 35 | 1750 | XLD7.5-7-43 | 7.5 | 6106 | 7569 |

SJ4.5×5.0 | 4500×5000 | 71.57 | 35 | 1750 | XLD7.5-7-43 | 7.5 | 7506 | 10864 |

SJ5.0×5.6 | 5000×5600 | 98 | 31 | 2046 | XLD11-8-47 | 11 | 10483 | 14291 |

SJ5.5×6.0 | 5500×6000 | 112 | 31 | 2100 | XLD11-8-47 | 11 | 14209 | 18745 |

Φ6×6.5 | 6000×6500 | 170 | 24.9 | 2300 | XLD18.5-9-35 | 18.5 | 16164 | 21006 |

Φ6.5×7 | 6500×7000 | 215 | twenty three | 2400 | XLD18.5-9-43 | twenty two | 17190 | 25567 |

Φ7.0×7.5 | 7000×7500 | 245.4 | twenty one | 2400 | XLD22-10-47 | twenty two | 22091 | 30486 |

SJ7.5×8.0 | 7500×8000 | 268.6 | twenty one | 2900 | XLD22-10-47 | twenty two | 26958 | 34365 |

SJ8.0×8.5 | 8000×8500 | 342 | 16.4 | 3200 | Y250M-8 | 30 | 33489 | 42468 |

Φ8.5×9 | 8500×9000 | 395 | 18.5 | 3300 | Y250M-8 | 30 | 36696 | 46623 |

Φ9.5×10 | 9500×10000 | 648 | 16.6 | 3750 | Y280S-8 | 37 | 46261 | 59786 |

Φ10.5×11 | 10500×11000 | 900 | 13.28 | 4400 | Y315S | 55 | 56888 | 72647 |

Φ11.5×12 | 11500×12000 | 1190 | 12.1 | 4600 | Y315M-8 | 75 | 67669 | 95669 |

Φ12×13 | 12000×13000 | 1414 | 13.4 | 4600 | Y315L1-8 | Post-90s | 88418 | 120635 |

Φ13×14 | 13000×14000 | 1740 | 10.7 | 5200 | JR125-8 | 110 | 113669 | 148666 |

success case

VIEW MORE

You may like

-

Gold Mining Leaching Tank/CIL Small Gold Processing Plant Mixing Tank

-

Mineral mud mixing tank Mixing tank Mineral mixing barrel

-

Mixing tank high-efficiency high-quality mixing tank / mineral mixer / mixing bucket

-

XB-1000 gold stirring leaching tank

-

Mixed leaching tank / gold ore stirring leaching tank

-

High-efficiency beneficiation mixing mixing tank gold ore tailings leaching processing plant mixing mixing tank with agitator

-

Energy-saving gold stirring leaching tank

-

High quality vibrating table top of 6S vibrating table for gold ore separation

-

High-quality mining barreled equipment gold leaching mixing tank

-

African hot selling gold ore process line mine mixer chemical stirring leaching tank

Other Products

-

$100.00 / set

$100.00 / set

Related Search

double impeller leach tank

high quality pdh equipment

high quality mining thickener

high quality impeller stainless

automatic gypsum powder equipment with high quality

high quality small sand blast equipment china

high quality vacuum sealing equipment

high quality auto parts

high pressure processing equipment

high quality industrial dehumidifiers