Low cost mud water sludge thickener liquid thickener

-

Supplier: Luoyang Longding Environmental Technology Co., Ltd. -

Region: Henan, China -

Contact: Ms Jessie Liang -

Price: $25000.00 /set -

Min. Order: 1 set

| Core component warranty: | 1 year | Supply capacity: | 20 sets per month |

| payment terms: | L/C, Western Union, T/T | product name: | Dewatered sludge mining thickener |

| Marketing type: | Hot Products of 2019 | usage: | Slurry purification |

| Health status: | new | Function: | Tailings thickener |

| Dimensions (length*width*height): | rely on | Warranty: | 1 year |

| Mechanical test report: | if | Certification: | International Organization for Standardization |

| Core components: | Motors, pumps | brand: | LDHB |

| color: | Blue, gray, customized | Package preview: | |

| Showroom location: | Philippines, Indonesia, Chile, Sri Lanka, Malaysia, Australia | Video outbound inspection: | if |

| Motor type: | AC motor | Weight (kg): | 1500 |

| method: | Automatic purification and sludge removal | Packaging details: | Standard packaging: The normal packaging of the main unit is plastic sheeting, and the accessories are wooden boxes. The wooden boxes are fumigated, and can also be packaged according to customer special requirements. |

| application: | Industry, chemicals, mining, construction, wastewater treatment | After-sales service provided: | Online support |

| Production capacity: | rely on | Applicable industries: | Manufacturing plants, energy and mining |

| Thickener weight: | rely on | type: | Mining concentrator |

| Place of origin: | Henan, China | Key words: | Concentration classifier |

| port: | Shanghai |

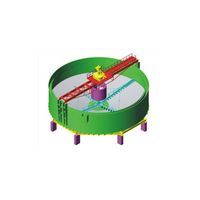

Paste thickener

This product is a rapid device precipitation device that can be combined into production line system production equipment and is widely used in factories.Aggregates, mineral processing precious metals, ceramics, glassand other industries.

working principle

LDHB paste concentrator is a solid-liquid separation equipment based on gravity sedimentation. When working, the solid particles suspended in the slurry in the center of the concentrator settle under the action of gravity, and the upper part becomes clear water, thereby achieving solid-liquid separation.

Slurry wastewater with a solid content of 2%-15% can be raised to 60%-70% slurry through gravity sedimentation. The upper part of the tank can realize the overflow of clean water, thereby achieving the purpose of slurry purification and solid-liquid separation.

Model | capacity (cubic meters/hour) | Tank height (mm) | Tank volume (cubic meter) | Dimensions (mm) |

S3040 | <50 | φ3000X4000 | 35 | φ3000X8860 |

S3060 | 50-100 | φ3000X6000 | 50 | φ3000X10860 |

S6030 | 100-150 | φ6000X3000 | 100 | φ6000X9400 |

S6040 | 150-200 | φ6000X4000 | 130 | φ6000X10400 |

S6050 | 200-250 | φ6000X5000 | 160 | φ6000X11400 |

S6060 | 250-300 | φ6000X6000 | 190 | φ6000X12400 |

S8045 | 350-400 | φ8000X4500 | 260 | φ8000X10600 |

S8060 | 400-500 | φ8000X6000 | 300 | φ8000X12100 |

main feature

1. The high-efficiency paste concentrator has a slender body, and flocculant is added during the concentration process to accelerate the concentration process of material settling and overflow water clarification.

2. It adopts the working principles of suspension filtration, media adsorption and sedimentation, without purification membrane and no wearing parts.

3. The tank body is made of high-quality carbon steel (or stainless steel, epoxy fiberglass, etc.) and has good strength and corrosion resistance.

4. Low cost of chemicals, large processing capacity, high processing efficiency and stable performance.

5. Small size, small footprint and easy installation.

6. The service life of the whole machine is 10-15 years, the one-time investment is small, and the economic benefits are significant.

7. The processing capacity is higher than that of traditional concentrators, and the overflow water quality can meet national discharge standards.

-

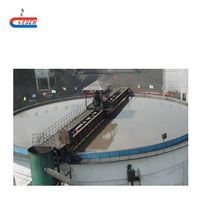

Hua Center Transmission Concentrate Tailings Thickener Dehydration

-

Ex-factory price copper-iron-lithium ore sedimentation tank sludge thickener

-

Fully automatic mine tailings concentrate treatment mud sewage sludge dehydration high-efficiency thickener price

-

Sludge Collector Circular Settling Thickener Tank Sludge Scraper Peripheral Drive Sludge Classifier Thickener Price For Sale

-

Gold ore cyanide leaching plant gold ore concentrator

-

Factory price sedimentation tank NZS-3 slime thickener for sale

-

Tailings gold beneficiation high-efficiency thickener

-

mine iron ore dewatering thickener/slurry sludge thickener tank sedimentation tank

-

Low Price Sludge Thickening Tank Supplier

-

Circular concentration clarifier gravity concentration tank

Other Products

-

$100000.00 / set

$100000.00 / set -

$100000.00 / set

$100000.00 / set