Ex-factory price copper-iron-lithium ore sedimentation tank sludge thickener

-

Supplier: Jiangxi Victor International Mining Equipment Co., Ltd. -

Region: Jiangxi, China -

Contact: Ms zhang haohao -

Price: $20000.00 /set -

Min. Order: 1 set

| Concentrator diameter (m): | 1.8-45 | Warranty: | 1 year |

| Weight (kg): | 5000 | brand: | Sikender |

| Install: | Technical support | Packaging Details: | Main gold and mercury stills in bare and bulk containers, spare parts in wooden boxes or according to your special requirements |

| Motor type: | AC motor | Bucket lifting height (m): | 0.16-0.2 |

| Production capacity: | 5-1400 tons/day | Applicable industries: | Energy and Mining |

| Depth of concentration tank (m): | 1.8-4.64 | type: | Mine concentrator |

| Core components: | engine | Core component warranty: | 1 year |

| color: | customizable | price: | Competitive |

| application: | chemical industry, construction, | Showroom location: | Egypt, Canada, Turkey, United Kingdom, United States, Brazil, Pakistan, India, Russia, Spain, Thailand, Argentina, South Korea, Romania, Bangladesh, South Africa, Ukraine, Kyrgyzstan, Malaysia, Australia |

| Dimensions (L*W*H): | depending on the model | Marketing Type: | Hot Products of 2019 |

| port: | Xiamen, Shenzhen, | Deposition area (㎡): | 2.54-1714 |

| Supply capacity: | 200 sets per month | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| product name: | thickener | OEM: | Yes |

| Function: | Mineral dressing densification thickener | Health status: | new |

| Video outbound inspection: | if | Mechanical test report: | if |

| Origin: | Jiangxi, China |

Ex-factory price for sale sedimentation tank sludge thickener product application

Mine thickeners are widely used for concentrate concentration and tailings dehydration before mine filtration, and can also be used for solid slurry concentration and purification in coal, chemical, construction, waste supply, wastewater treatment and other industries.

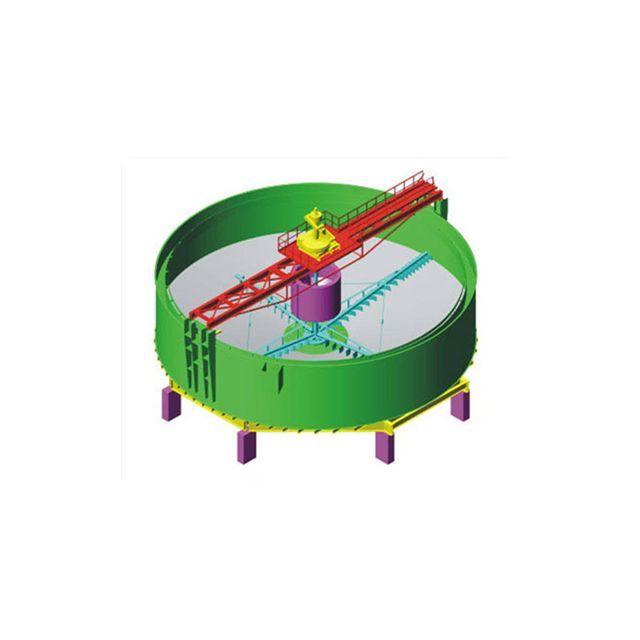

The working principle of the sedimentation tank sludge thickener sold at the ex-factory price

The mine thickener is composed of a circular thickener and a rake scraper. The solid particles are suspended in the thickener and settled by gravity, and the upper slurry becomes clear water to achieve separation. The sediment at the bottom of the thickener is continuously scraped and discharged by the rake, and overflows cleanly from the upper part.

Main features of sedimentation tank sludge thickener for sale at ex-factory price

1. There is a degassing chamber to prevent solid particles from adhering to the air bubbles and make the solid particles fall like a parachute.

2. The feeding pipe is lower than the slurry surface; it can prevent the air from being brought in during feeding

3. The feeding sleeve is moved to a lower position and equipped with a receiving plate. Therefore, the fed slurry falls down evenly and stably, preventing the rolling phenomenon caused by the residual pressure of feeding.

4. There is an inner overflow weir to make the slurry flow according to the pre-designed route, avoid short circuit and expand the deposition area

5. The inner overflow weir is made into a zigzag shape, which eliminates the partial water absorption caused by the uneven overflow weir.

6. The nail line is changed from a slash to a curve. Therefore, the discharge underflow density is higher and the processing capacity is improved.

Application of sedimentation tank sludge thickener for sale at ex-factory price

Widely used in metallurgy, chemical industry, coal, non-metallic mineral processing, environmental protection and other industries

Technical parameters of sedimentation tank sludge thickener for sale at ex-factory price

Model | D water tank | tank depth | Sedimentary area | capacity | motor model | Motor Power |

(mm) | (mm) | (square meter) | (t/day) | (kilowatt) | ||

NZSG-2.5 | 2500 | 1850 | 4.9 | 5-10.8 | Y90L-6 | 1.1 |

NZSG-3A | 3000 | 1800 | 7 | 5-23.3 | Y100L-6 | 1.5 |

NZSG-3 | 3600 | 10.2 | 5-28.5 | |||

NZSG-5 | 5000 | 2956 | 16 | 16-90 | Y90L-4 | |

NZSG-6 | 6000 | 28.3 | 98 | |||

NZSG-7 | 7000 | 3000 | 38.5 | 140 | Y112M-6 | 2.2 |

NZSG-8 | 8000 | 3318 | 50.2 | 185 | Y132S-6 | 3 |

NZSG-9 | 9000 | 3376 | 63 | 210 | ||

NZSG-12 | 12000 | 3600 | 113 | 370 | ||

NZSG-15 | 15000 | 4000 | 176 | Chapter 580 | Y132(M2)-6 | 5.5 |

NZSG-18 | 18000 | 4400 | 255 | 960 | YCT200-413 | 7.5 |

NZSG-20 | 20000 | 4400 | 315 | 1400 | Y160(M2)-8 |

our service

1) Pre-sale service:Provide you with scheme design, process design and selection of suitable equipment for free.

2) Medium sales service:Accompany you to complete the equipment acceptance, draft the construction plan and detailed process, and complete the export process

3) After-sales service:Provide thoughtful technical guidance on installation, commissioning and operator training. If you need us, we are always at your service.

pack:FCL, LCL export standard container 20GP/40GP/40HQ.

FCL:The main mechanical gold shakers are in bare and bulk containers, and the spare parts are in wooden boxes or according to your special requirements

LCL:The machinery is packaged in a steel frame, and the base and deck are packaged separately.

Shipping:By sea, by air or by express, it's up to you.

payment terms:

T/T or L/Cis preferred.

wire transfer:30% deposit, the balance paid before shipment

We will take photos of your products when finished and show them to you before delivery. And inform you of any latest information, including shipping information, before you receive the goods, so you can rest assured

delivery time:Shipped within 15 days after payment

-

Low cost mud water sludge thickener liquid thickener

-

Hua Center Transmission Concentrate Tailings Thickener Dehydration

-

Fully automatic mine tailings concentrate treatment mud sewage sludge dehydration high-efficiency thickener price

-

Sludge Collector Circular Settling Thickener Tank Sludge Scraper Peripheral Drive Sludge Classifier Thickener Price For Sale

-

Gold ore cyanide leaching plant gold ore concentrator

-

Factory price sedimentation tank NZS-3 slime thickener for sale

-

Tailings gold beneficiation high-efficiency thickener

-

mine iron ore dewatering thickener/slurry sludge thickener tank sedimentation tank

-

Low Price Sludge Thickening Tank Supplier

-

Circular concentration clarifier gravity concentration tank

Other Products

-

$2500.00 - $2900.00 / set

$2500.00 - $2900.00 / set -

$1250.00 - $1300.00 / set

$1250.00 - $1300.00 / set