Professional large-scale 2000 type scrap iron shredder, scrap steel shredder, waste tire shredder

-

Supplier: Zhengzhou Huahong Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr hong hua -

Price: $7000.00 / 1 - 1 sets

$6900.00 / >=2 sets -

Min. Order: 1 set

| strength: | 55kw X 2,55kw X 2 | model: | 2000 models |

| Origin: | China | payment terms: | L/C, T/T, Western Union, Cash |

| After-sales service provided: | Engineers available to service machinery overseas | use: | wood, metal plastic, electrical appliances, books, paper, |

| Origin: | Henan, China | market: | Asia, Africa, Middle East, Arab States, Europe, America, Latin America |

| Supply capacity: | 100 sets per month | color: | As required |

| Certification: | ISO9001:2000 | Dimensions (L*W*H): | 5500X2100X2900mm |

| brand: | Hua Hong | capacity: | 5-15 tons/hour |

| Shaft design: | double | application: | wood, rubber, tires, metal, plastic, electrical appliances, paper, |

| port: | Tianjin, Shanghai, Qingdao | Voltage: | Require |

| weight: | 15 tons | Health status: | new |

| Packaging Details: | Wooden box, standard export | Warranty: | 3 years |

| Plastic Type: | Scrap steel, tires, plastics... |

Large 2000 type scrap iron shredder, scrap steel shredder, waste tire shredder

introduce:

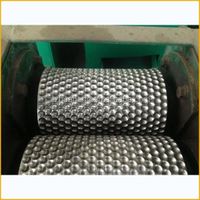

Double-shaft shredders are also called tire shredders, which are generally used for

Shreds hard-to-tear materials such as plastics, rubber, fibers, paper, wood, electronic parts,

Cables and other solid materials such as socket material, plastic headers, PET bottles, cardboard,

Planks, lumber, plastic barrels. The double-shaft shredder can tear the material into 3-10cm products.

feature:

1. This machine can crush all hard blocks that single-shaft shredders cannot crush

Such as powder, baskets, pipes, plates, wood, tires, scrap iron barrels, large pieces, etc.;

2. Ultra-thick plate precision machining composite structure frame,

Powerful wide-angle rotating shaft hexagonal column, large diameter solid feed hopper,

So you can rest assured to invest a lot of raw materials;

3. Unique rotary knife design in terms of thickness, shape and arrangement

Orderly, strong cutting ability, sharp blade, high crushing efficiency;

4. Low speed, low noise, less dust;

5. The knife is made of special alloy steel, strong and durable.

Suitable for crushing the following materials:

- Bucket products: plastic buckets, iron buckets, paint buckets, intermediate bulk containers (IBC), trash cans

- Garbage: domestic waste, medical waste, kitchen waste, industrial waste, park waste

-Plastic products: plastic bottles, plastic frames, plastic blocks, plastic jars

-Metal products: aluminum profiles, oil filters, car casings, cans, metal cans

-Paper: newspaper, cardboard, corrugated paper, copy paper

Technical parameters of double shaft shredder

Model | strength (kilowatt) | quantity rotary knife | knife thickness (mm) | Tool diameter (mm) | Number of blades | dimension crushing room (mm) | output (kg/hour) | Dimensions length*width*height) | weight (Kilogram) |

Ø250x600 | 11 | 12 | 50 | φ280 | 5 | 600*550 | 300~800 | 3000*2000*2100 | about 2800 |

Ø300x600 | 15 | 12 | 50 | φ280 | 5 | 600*550 | 300~800 | 3000*2000*2100 | about 2900 |

Ø300x800 | twenty two | 16 | 50 | φ300 | 5 | 800*600 | 500~1500 | 3600*2000*2420 | about 4100 |

Ø300x1000 | 22x2 | 16 | 50 | φ300 | 5 | 800*600 | 500~1500 | 3600*2000*2420 | about 4300 |

Ø600x800 | 2×30 | 20 | 50 | φ350 | 5 | 1000*700 | 1500~2800 | 3500*2000*2820 | about 6500 |

Ø400x1200 | 2*30 | twenty four | 50 | φ400 | 5 | 1200*800 | 1500~2500 | 3800*2000*2820 | about 7000 |

Ø400x1500 | 2×37 | twenty two | 70 | φ450 | 5 | 1600*900 | 2000~3000 | 4700*2000*3000 | about 10500 |

English standard parameters:

Model | strength (kilowatt) | quantity rotary knife | knife thickness (mm) | Tool diameter (mm) | Number of blades | output (kg/hour) | weight (Kilogram) |

10''x24'' | 11 | 12 | 2'' | 11.2'' | 5 | 300~800 | about 2800 |

12''x32'' | twenty two | 16 | 2'' | 12'' | 5 | 500~1500 | about 4100 |

12''x40'' | 22x2 | 16 | 2'' | 12'' | 5 | 500~1500 | about 4300 |

24''x32'' | 2×30 | 20 | 50 | 16'' | 5 | 1500~2800 | about 6500 |

advantage:

1. Using the latest German paper shredding technology

2. Low noise

3. The production capacity is about 8000-40000kg/h

4. Wide range of uses Mainly suitable for crushing wood, rubber, tires and plastics

5. Long life

6. The blade is very durable and can be replaced four times for use, easy to use.

7. Adapt to PIC control, automatic control

Spare parts (unpainted):

Customers visit our factory:

We often use wooden boxes, and we also make according to customers' requirements.

pre-sale service:

Be a good consultant and assistant to customers to ensure that customers' investment is returned

high profit.

1. The ore or slag is known in sufficient detail, and sometimes it is necessary to test certain ores.

2. Select the appropriate type of equipment for customers.

3. Can design and develop customized products and processing technology to meet

customer's special needs,

4. Engineers can be sent to the customer site to observe and propose an optimization plan

therefore.

Sale service:

Every customer is treated with respect, convenience and reliability will be provided. we are committed

Help you get as much benefit as possible.

1. The goods must be inspected before delivery.

2. Assist in developing construction plans by providing all drawings and data required.

3. The most favorable plan with guaranteed quality.

4. Communicate in time to ensure project improvement and your requirements are met.

After-sales service:

1. Ability to install, debug and debug equipment.

2. Commitment to training on-site technicians and workers.

3. The service engineer can only leave after ensuring that the entire line is installed;

The adjustment is complete.

4. If there is any fault or question about the machine or processing line, please contact us, we can

at any time.

-

-

Plastic Crusher/Powerful Granule/Cutter WSGE-400/High Quality Film Powerful Plastic Crusher

-

Efficient and multifunctional crushing rubber/tire plastic crusher grinder for sale

-

Heavy duty industrial waste tire shredder, scrap car tire shredder, tire shredding

-

waste plastic shredder pet shredder for shredding plastic

-

Small Portable Dual Shaft Household Scrap Metal Tire Plastic Coconut Pallet Mobile Tire Shredder Metal

-

Double shaft shredder edge blade

-

Industrial Type 1200 Plastic Waste Wood/Metal/Rubber/Plastic/Scrap/Shredder Blades

-

Small waste plastic recycling machine/metal shredder/metal shredder

-

Automatic Plastic Shredder Industrial Heavy Duty Single Shaft Steel Shredder Wood Shredder

Other Products

-

$20000.00 / set

$20000.00 / set -

$2900.00 - $3000.00 / set

$2900.00 - $3000.00 / set -

$12000.00 - $55000.00 / set

$12000.00 - $55000.00 / set -

$2000.00 / set

$2000.00 / set -

$1000.00 / set

$1000.00 / set -

$1000.00 - $3200.00 / set

$1000.00 - $3200.00 / set -

$2900.00 - $3000.00 / set

$2900.00 - $3000.00 / set -

$3800.00 - $4000.00 / set

$3800.00 - $4000.00 / set -

$4000.00 / set

$4000.00 / set -

$1000.00 / set

$1000.00 / set