Small gold ore mill, small wet mill, small gold ore mill

-

Supplier: Zhengzhou Huahong Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr hong hua -

Price: $3000.00 / 1 - 1 sets

$2900.00 / >=2 sets -

Min. Order: 1 set

| strength: | 2.5 kW | Origin: | Henan, China |

| Warranty: | 1 year | After-sales service provided: | Engineers available to repair machinery overseas |

| application: | Used to separate gold, molybdenum, silver, copper, lead, iron, zinc, etc. | brand: | Hua Hong |

| Dimensions (L*W*H): | 1200*1000*1400mm | payment terms: | L/C, D/P, T/T, Western Union |

| Packaging Details: | Shipped in standard container or upon request. | Health status: | new |

| type: | wet mill | Raw material capacity: | 0.5-1 ton/hour |

| Motor type: | AC motor | Install: | under the guidance of engineers |

| Spare parts supply: | entire service life | Speed (rev/min): | 10-16 days |

| color: | upon request | Certification: | International Organization for Standardization; CE |

| weight: | 500 kg | port: | Qingdao, Tianjin, Shanghai or as required |

| model: | 500 | Supply capacity: | 100 sets per month |

| Production capacity (tons/hour): | 0.5-1 | spare parts: | grinding ring |

| Raw material type: | Granular gold dust | Main exporting countries: | Asia, Africa, South Africa, Europe, etc. |

| Raw material size: | less than 20mm |

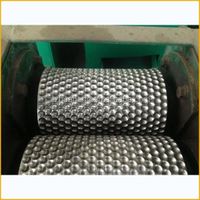

Small gold ore mill, small wet mill, small gold ore mill

Small Gold Mill Specifications

1. High output, easy to move;

2. Easy to operate.

3. Less energy consumption and moderate price;

4. Perfect beneficiation equipment for gold ore, iron ore, zinc ore, lead ore, etc.

Features of small gold mill

The small gold mill mainly achieves water balance, uniform proportioning, low gas content, and improves molding rate and molding quality through mixing, rolling, and crushing of raw materials. The finished product of this type of mill has the characteristics of high density, good strength, and no porosity. This product has the advantages of high efficiency, energy saving, and high output. This product is used for recycling tailings in the ironmaking process, without losing ore powder, and fully and effectively utilizing resources.

small gold millIt is specially designed by us according to customer requirements

Yemeni customers come to visit our factory

Sowing methods and techniquessmall gold mill

1. After the gold grinding machine is installed, add 5 kg of mercury to the bottom of the tank to work normally.

2. The staff of each shaft put gold sand into it once, add 1 kg of mercury continuously each time, collect it in the sand bottom and mercury, put the mercury into the gold vessel, wrap the mercury with a red cloth with high density and wring out the mercury, open the red The cloth on the left is gold sand inside.

3. Each class starts with one kilogram of mercury. Another way is to collect the gold with a gold grab cloth or a gold mercury blanket placed on the back plate.

Technical datasmall gold mill

Model | Specification | Input size (mm) | Processing capacity (ton/hour) | speed (rev/min) | engine (kilowatt) | weight (Ton) |

1600 | 1600×400×±20 | less than 30mm | 4 | 20-22 days | 6-30 | number 17 |

1500A | 1500×400×±20 | 3 | 20-22 days | 6-22 | 15 | |

1500B | 1500×350×±20 | 2.5-3 | 20-22 days | 6-22 | 14 | |

1500℃ | 1500×300×±20 | 2-2.5 | 20-22 days | 6-22 | 12.5 | |

1400 | 1400×250×±20 | 1.5-2 | 16-18 days | 6-18.5 | 9.5 | |

1300 | 1300×250×±20 | 1.5 | 21-23 | 6-15 | 7.8 | |

1200A | 1200×220×±20 | 0.9-1.2 | 16-18 days | 4-7.5 | 6.0 | |

1200B | 1200×200×±20 | 0.8-0.1 | 21-23 | 4-7.5 | 5.8 | |

1100 | 1100×200×±10 | 0.6-0.8 | 16-18 days | 4-5.5 | 5.5 | |

1000 | 1000×200×±10 | 0.5 | 21-23 | 4-5.5 | 4.5 | |

900 | 900×150×±10 | 0.3 | 17-19 days | 3 | 3.2 |

The attached parameters are for reference only, smaller or larger sizes can be customized upon request

small gold millThe model shipped to Yemen is a jaw crusher (the customer uses it to crush gold ore)

pre-sale service

(1) Freely design the production line process and equipment layout according to the site conditions.

(2) Provide the basic diagram of the equipment.

(3) Provide technical parameters of peripheral equipment.

(4) During the operation, if the user needs to adjust the layout and application, we can provide technical services for free.

(5) During the operation process, we only charge fees if users are willing to upgrade their equipment if we have superior technology.

After-sales service

(1) During the installation and commissioning process, we will send technicians to the site to guide the installation and commissioning. We also provide training services.

(2) If the equipment fails due to improper operation by the user, we will be responsible for the maintenance and charge corresponding fees.

(3) The spare parts we provide have favorable price and long-lasting maintenance. After the warranty period, if the equipment needs to be repaired, we only charge the cost price.

We also supply various types of gold mining machinery, such as centrifugal refiners, spiral chutes, gold washing machines, jigs, shakers, etc.

This is the spare part for this machinesmall gold mill

Gearbox reducer and other spare parts can be supplied separately according to customer requirements

If you need a manufacturer with independent research and development capabilities, please choose us.

Zhengzhou Huahong Machinery is a famous brand in China, and its products are exported to Europe, America and the Middle East.

If you need a reliable and honest supplier, please choose Zhengzhou Huahong Machinery Co., Ltd.

We have various quality certifications: CE ISO9001 Alibaba third-party certification, etc.

If you want to save equipment cost, please contact our company.

We are an OEM (Original Equipment Manufacturer), so our manufacturer's price is much lower (at least 10%) than the market price. Free equipped with machine parts for all partners and customers.

If you need it urgently, please place the order to us,

We can successfully manage it in a week. We have excellent service: only 20 working days delivery time and lifetime free maintenance.

Welcome to visit our factory!

-

High efficiency rock gold grinding equipment wet disc grinder for sale

-

Professional 1000 tons/day cement grinding station ball mill price

-

Black graphite vibrating ball mill

-

Nano powder steel ball mill grinder laboratory grid ball mill with grinding ball grinder

-

Diesel engine ball mill for gold mine development for sale

-

1600 gold mill with gearbox, china wet disc mill for sale

-

Superfine Powder Complete Production Line Fluidized Bed Jet Mill

-

Energy-saving gold mine rock crusher quartz gold ore stone mill small gold ball mill

-

1100 wet mill reducer 400 gears

-

Chinese Wet Pot Mill Gold Choice

Other Products

-

$20000.00 / set

$20000.00 / set -

$12000.00 - $55000.00 / set

$12000.00 - $55000.00 / set -

$2000.00 / set

$2000.00 / set -

$1000.00 / set

$1000.00 / set -

$1000.00 - $3200.00 / set

$1000.00 - $3200.00 / set -

$2900.00 - $3000.00 / set

$2900.00 - $3000.00 / set -

$6900.00 - $7000.00 / set

$6900.00 - $7000.00 / set -

$3800.00 - $4000.00 / set

$3800.00 - $4000.00 / set -

$4000.00 / set

$4000.00 / set -

$1000.00 / set

$1000.00 / set