PE-250*400 diesel jaw crusher engine ,stone jaw crusher ,stone crusher with diesel engine

-

Supplier: Zhengzhou Huahong Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr hong hua -

Price: $1000.00 /set -

Min. Order: 1 set

| Condition: | New; | Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; |

| Port: | tianjing qingdao shanghai; | Package Preview: | ; |

| Warranty: | one year; | Machinery Test Report: | Provided; |

| Weight: | 2.8t; | Packaging Detail: | wooden case ,stander container; |

| color: | as your required; | Key Selling Points: | Portable; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,cash; | disign: | innovation; |

| Showroom Location: | None; | Type: | Jaw Crusher; |

| Video outgoing-inspection: | Provided; | Dimension(L*W*H): | 1300*1090*1270; |

| Core Components: | Motor; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Marketing Type: | New Product 2020; | Supply Ability: | 100.0 Set/Sets per Month; |

| Local Service Location: | None; | Capacity(t/h): | 5-20; |

| Motor Type: | AC Motor; | Certification: | CE ISO GOST CIQ; |

| Brand Name: | huahong; | Warranty of core components: | 1 YEAR; |

| Application: | stone, ore,rock; | Place of Origin: | Henan China; |

| visit factory: | supply; |

The work method of Jaw Crusher is as follow.

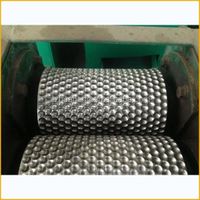

All kinds of jaw crusher picture show

Jaw crusher with feeder and conveyor

mobile jaw crusher with vibrating screen and convyor

250*750 jaw crusher with conveyor belt

sationary 250*400 jaw crusher with convyor belt ,feeder and vibrating screen

sationary 250*400 jaw crusher with leg

mobile jaw crusher

jaw crusher

jaw crusher with electric motor

Schematics of jaw crusher

The structure of the Epoch consists mainly of racks, eccentric shafts, large pulleys, flywheels, movable jaws, side guards, brackets, rear brackets, drift screws, return springs, fixed jaws, and movable jaws. The brackets also play an insurance role.

The jaw crusher, abbreviated as Epox (also known as the tiger's mouth), appeared in 1858 and was first widely used in road construction projects and later applied to mines. With a large crushing ratio and high yield. Jaw crusher products have the characteristics of uniform particle size, simple structure, reliable work, easy maintenance and economical operation.

Product dates

| Model | Feed opening size (mm) |

Max feed size(mm) |

Adjustable range (mm) |

Capacity (t/h) |

Eccentric shaft rotary speed (r/min) |

Motor power (kw) |

Total weight (t) |

Overall dimensions (L*W*H)(mm) |

| PE-150×250 | 150×250 | 125 | 10-40 | 1-3 | 250 | 5.5 | 0.8 | 720×660×850 |

| PE-200×300 | 200×300 | 180 | 15-50 | 2-6 | 260 | 7.5 | 1.2 | 910×750×990 |

| PE-200×350 | 200×350 | 180 | 18-70 | 3-10 | 260 | 11 | 1.5 | 1000×870×990 |

| PE-250×400 | 250×400 | 210 | 20-60 | 5-20 | 300 | 15 | 2.8 | 1300×1090×1270 |

| PE-400×600 | 400×600 | 340 | 40-100 | 16-60 | 275 | 30 | 7 | 1730×1730×1630 |

| PE-500×750 | 500×750 | 425 | 50-100 | 40-110 | 275 | 55 | 12 | 1980×2080×1870 |

| PE-600×750 | 600×750 | 500 | 150-200 | 80-240 | 275 | 55 | 15.8 | 2070×2000×1920 |

| PE-600×900 | 600×900 | 500 | 65-160 | 50-180 | 250 | 55 | 17 | 2190×2206×2300 |

| PE-750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 250 | 90-110 | 29 | 2660×2430×2800 |

| PE-800×1060 | 800×1060 | 640 | 160-220 | 130-330 | 250 | 110 | 29.8 | 2710×2430×2800 |

| PE-830×1060 | 830×1060 | 650 | 160-220 | 150-336 | 250 | 110 | 30.7 | 2740×2430×2800 |

| PE-870×1060 | 870×1060 | 660 | 200-260 | 190-336 | 250 | 110 | 31.5 | 2810×2430×2800 |

| PE-900×1060 | 900×1060 | 685 | 230-290 | 230-390 | 250 | 110 | 33 | 2870×2420×2940 |

| PE-900×1200 | 900×1200 | 750 | 95-165 | 220-450 | 200 | 110 | 52 | 3380×2870×3330 |

| PE-1000×1200 | 1000×1200 | 850 | 195-265 | 315-500 | 200 | 110 | 55 | 3480×2876×3330 |

| PE-1200×1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 180 | 160 | 100.9 | 4200×3300×3500 |

| PEX-150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 15 | 3.8 | 1200×1530×1060 |

| PEX-250×750 | 250×750 | 210 | 25-60 | 13-35 | 330 | 30 | 5.5 | 1380×1750×1540 |

| PEX-250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 330 | 30 | 7 | 1560×1950×1390 |

| PEX-250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 330 | 37 | 9.7 | 2140×1660×1500 |

| PEX-300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 55 | 15.6 | 2720×1950×1600 |

The jaw crusher packing is stamder wooden case ,we will change the package accroding your demands ,and delivery by ship ,reilway ,airplane or way accroding your requirement

After-sales service:

1. Installation, adjustment, and testing of equipment is available.2. Train of technicians and workers at site is promised.

3. Service engineers will not leave until ensuring the whole line running well after the installation & adjustment is finished.

4.If any failure or question about the machines or the processing line, contact us and we are available at any time.

About our company

1.Zhengzhou Huahong Machinery Equipment Co., Ltd. mainly produces iron selecting equipment,kinds of drederes, dredging equipment, sand washing and sand making equipment, gold panning equipment, magnetic separating, crusher and so on, there are more than hundred kinds of products.

2.We design produce various of products according to the customers requirement and geographical condition. It is a modern largescale mineral processing equipment manufacturer for research and development, engineering design, producing installation, commissioning and after sale service.

We also have large type jaw crusher, if you want to know more, please contact me! we offer to visit factory for free .

welcome to our factory ,we will provide the best product with the lowest price for you

Name ;Jessica

we chat ;+8613949058207

QQ;2623204968

whatsapp;+8613949058207

phone number ;+8613949058207

skype ;jessicakoukou1

my maill ;wenpang(at)huahongjixie.net.cn

-

Small rock crusher small mobile jaw crusher with vibrating screen manufacturing price

-

PE150x250 portable mobile small jaw crusher with vibrating screen

-

pe250x400 jaw crusher diesel engine or electric small portable jaw crusher price

-

Diesel Soil Crusher into Powder Mini Mobile Stone Crusher Stone Soil Crusher

-

Mobile Jaw Crusher/Stone Hammer Crusher

-

Good Price Portable Jaw Crusher China Supplier Basalt Jaw Crusher

-

Portable Complete Line Quarry Crushing Station Reliable Primary Price Small Jaw Crusher For Gravel

-

China Manufacturer Mining Machine Small Rock Crusher Hammer Crusher

-

Mobile Crusher Machinery Crawler Portable Rock Crusher in Zhengzhou, Henan, China

-

Hot Selling Small Mobile Jaw Crusher With Diesel Engine By Factory Small Stone Crusher Jaw Crusher Price

Other Products

-

$20000.00 / set

$20000.00 / set -

$2900.00 - $3000.00 / set

$2900.00 - $3000.00 / set -

$12000.00 - $55000.00 / set

$12000.00 - $55000.00 / set -

$2000.00 / set

$2000.00 / set -

$1000.00 / set

$1000.00 / set -

$1000.00 - $3200.00 / set

$1000.00 - $3200.00 / set -

$2900.00 - $3000.00 / set

$2900.00 - $3000.00 / set -

$6900.00 - $7000.00 / set

$6900.00 - $7000.00 / set -

$3800.00 - $4000.00 / set

$3800.00 - $4000.00 / set -

$4000.00 / set

$4000.00 / set