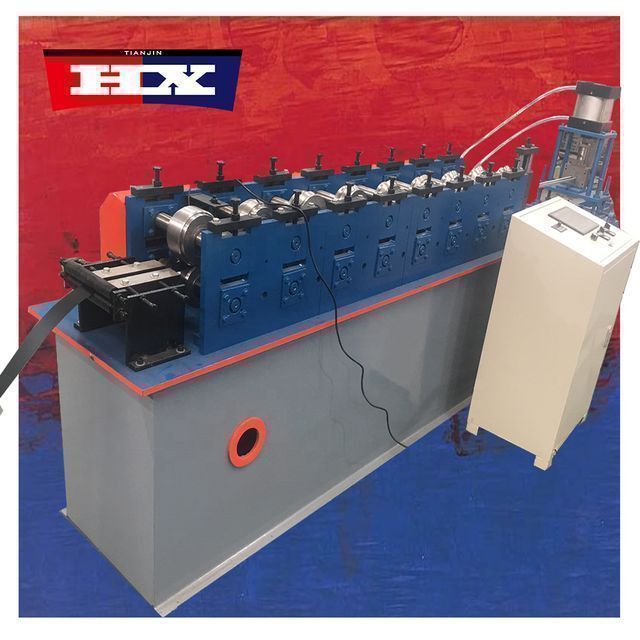

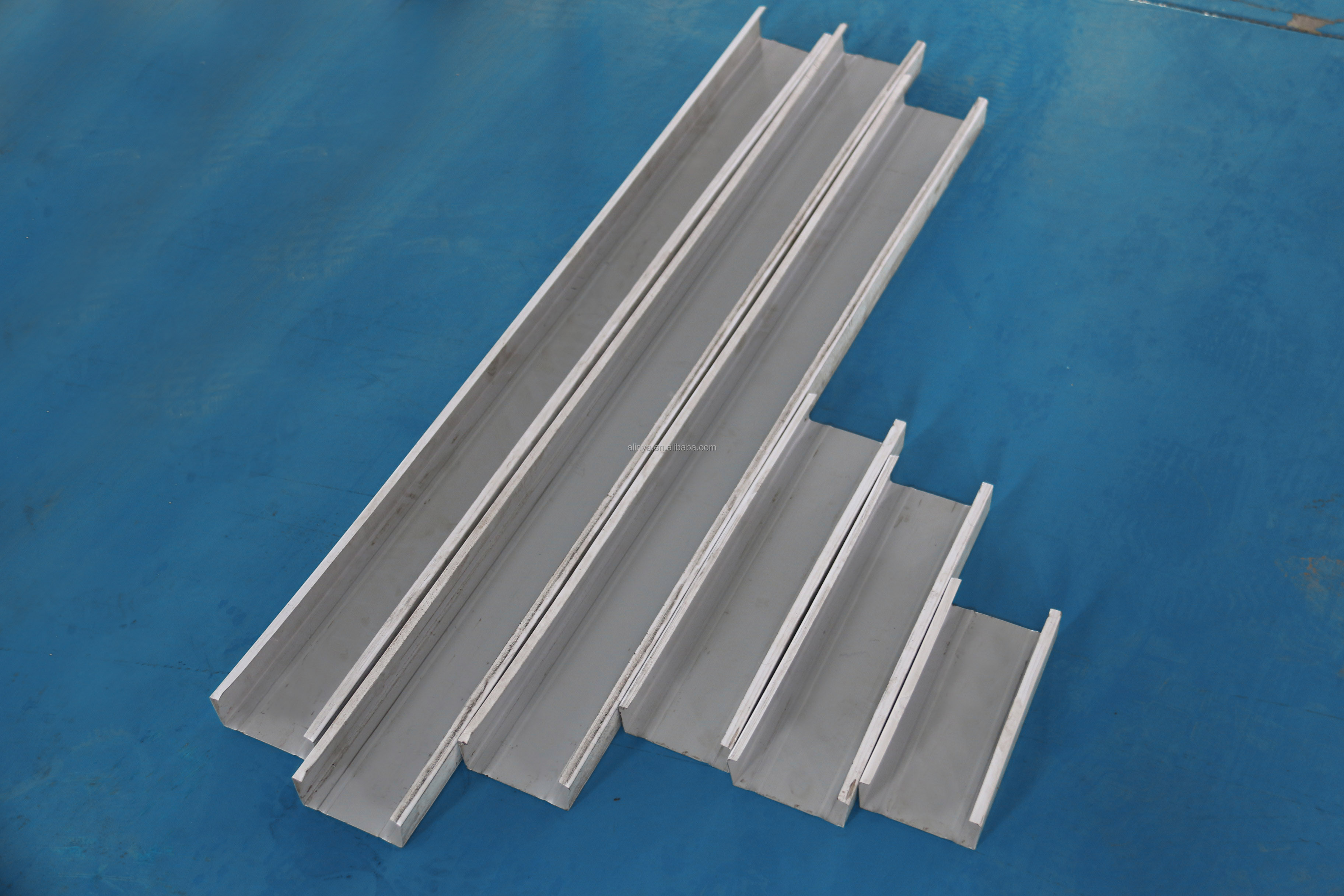

Popular c panel channel steel stud light weight keel equipment roll forming machine

-

Supplier: Haixing (tianjin) Imp. & Exp. Co., Ltd. -

Region: Tianjin, China -

Contact: Ms Alin Zhao -

Price: $9500.00 / 1 - 2 sets

$8600.00 / 3 - 10 sets

$7000.00 / 11 - 19 sets

$6200.00 / >=20 sets -

Min. Order: 1 set

Product details

| Packaging Details: | 1. A 40-foot container is required; 2. Suitable for shipping; 3. The main body of the roll forming machine is naked in the container and covered with plastic film. 4. Steel wire secures the machine in the container to prevent damage when shaking at sea. 5. Spare parts will be packed in the carton. 6. The receiving table is put into the carton. 7. Manual uncoiler bare package | product name: | Light keel forming machine |

| Applicable industries: | Building material stores, mechanical repair shops, manufacturing plants, construction works | Motor brand: | Chinese famous brand |

| Suitable for processing: | Aluminum zinc coil | Packaging Preview: | |

| Supply capacity: | 300 sets per month | Main selling point: | long lasting |

| brand: | delta | Warranty: | 2 years |

| Shaft Material: | 45# high quality carbon steel | use: | roof |

| Health status: | new | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

| place of origin; place of origin: | Hebei china | feature: | High speed and low energy consumption |

| Voltage: | 220/380/440V | Coil Thickness: | 0.3--0.8mm |

| Showroom location: | Canada, United States, Brazil, Peru, Indonesia, Pakistan, Mexico, Russia, Morocco, Kenya, Chile, Sri Lanka, South Africa, Nigeria, Australia | weight: | 3500 kg |

| Dimensions (L*W*H): | 5.8*0.8*1.5m | Marketing Type: | normal product |

| Introduction: | According to customer requirements | Working pressure: | 12-16Mpa |

| port: | Tianjin | Blade material: | Cr 12 high grade steel |

| Core Components Warranty: | 2 years | type: | Steel frame purlin machine |

| Video external inspection: | if | Production capacity: | 10-12m/min |

| Mechanical test report: | if | strength: | 4kW |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

Factory lifetime service!

China rollformer manufacturer direct factory high qualityczu keel machineISO9001/Ce/SGS price

Why choose us?

We care about user experienceThe controller is the "CPU" of the molding machine. We choose Siemens PLC from Japan. Get your employees hands-free with touch screen mode!We care about your concerns1. Capacity: 12-15 sets/month 2. Lead time: only 5-8 weeks for urgent ordersWe care about quality1. ISO, CE certificate 2. Adopt European quality standard 3. Choose the best materials and components

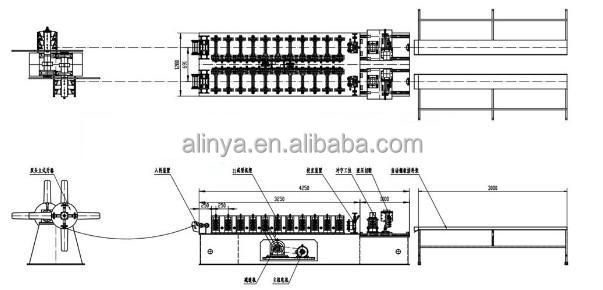

Do not. | Name | Specification |

1 | suitable for processing | (Painting) Galvanized Steel Strip |

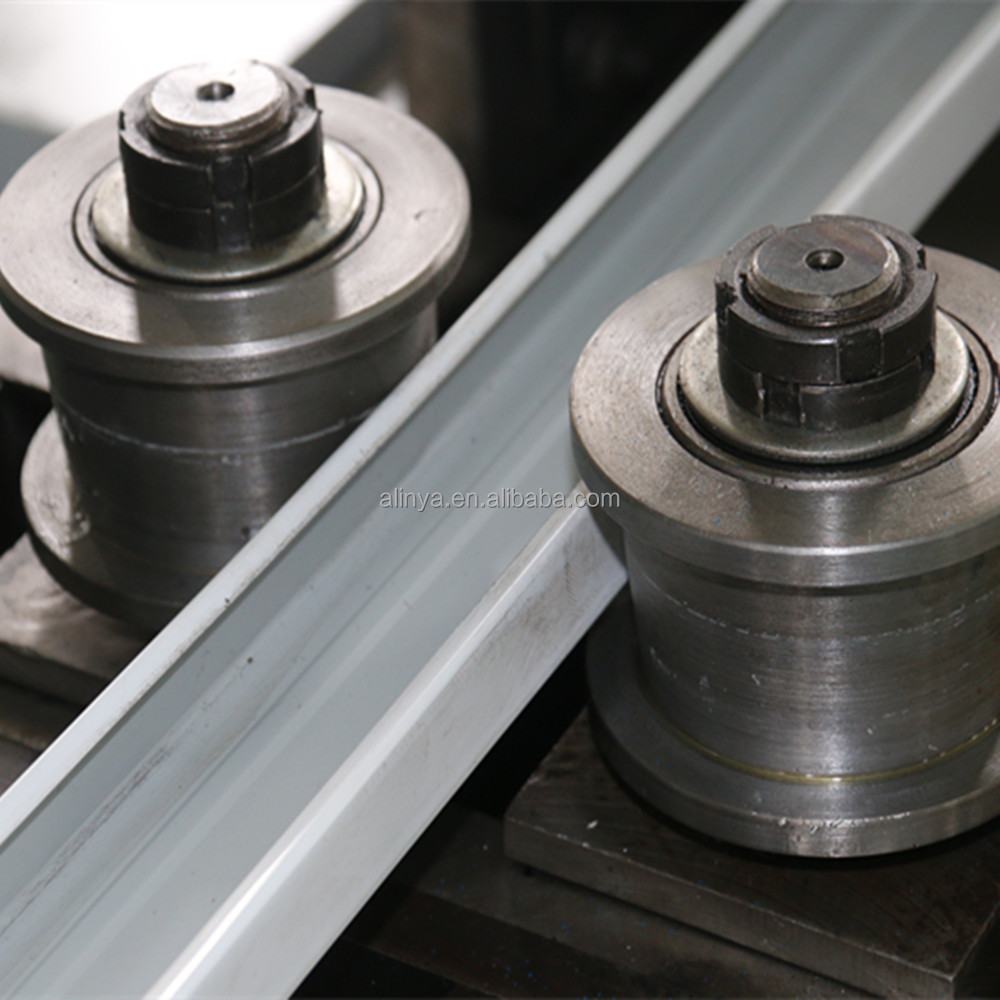

2 | roller | 12 lines |

3 | Main Frame | square steel frame |

4 | aspect | 5.5*0.6*1.5m |

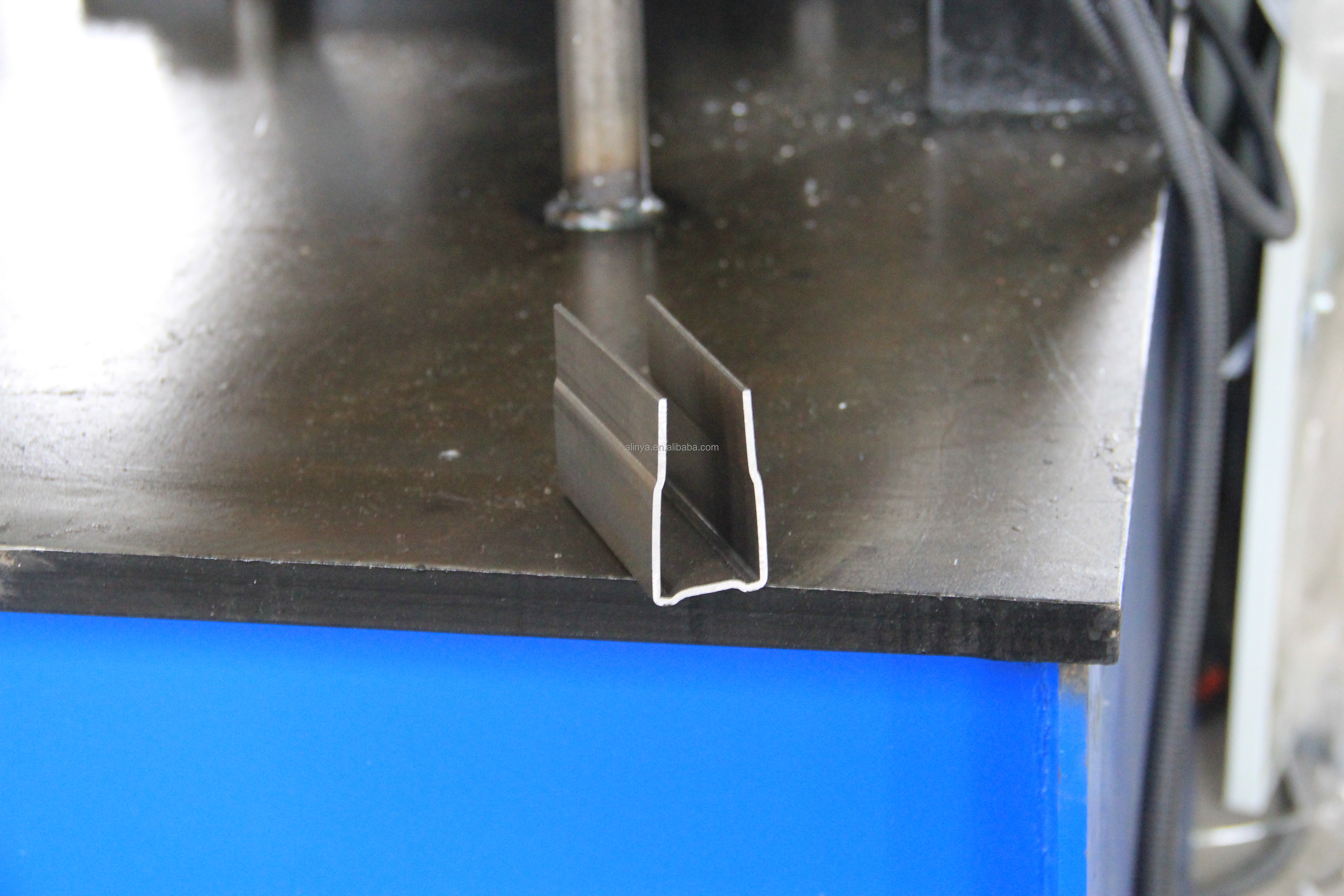

5 | wall panel size | archway |

6 | weight | About 3.2T |

8 | Motor Power | 5.5Kw |

9 | Pumping station motor | 3kW |

10 | plate thickness | 0.4mm - 0.8mm |

11 | productivity | 20m/min to 25m/min |

12 | cutting method | Hydraulic tracking cutting |

13 | Drum diameter | Φ50mm |

14 | Voltage | 380V 50Hz three-phase |

15 | Control System | PLC control |

16 | touch screen | delta |

17 | Rolled product | 45# forged steel plus chrome plate |

18 | length tolerance | ±2mm |

work process:

Unwinding→Feeding into the machine→Rolling→Length measurement→Automatic cutting→Receiving

Why choose this machine?

:) Fully automatic control system with PLC.

:) Simple operation: enter length and quantity on the control panel.

:) Two years free warranty, if any part is damaged for more than two years, please let us know and pay us, we will deliver any parts you need. And provide lifetime technical support for the machine.

Mechanical Parts

Name: Main molding machine Brand: HXRoller Material:High quality 45# forged steel,Roller surface polishing, hard plating, polishing surface and mold heat treatment can also keep the surface of the template smooth and not easy to leave marks during stamping.

Mechanical Parts

Name: Shearing Mechanism Brand: HX Motor-driven, automatic positioning, determining size, and cutting the target product.Cutting method:hydraulic cutting

Mechanical Parts

It conveys the product using welded steel and back-up rollers for collecting the finished product.2 pieces 3 meters

Can't find the machine you need?

Why not customize it! You can rely on our team! We have engineers with over 18 years of experience in the metal forming industry.

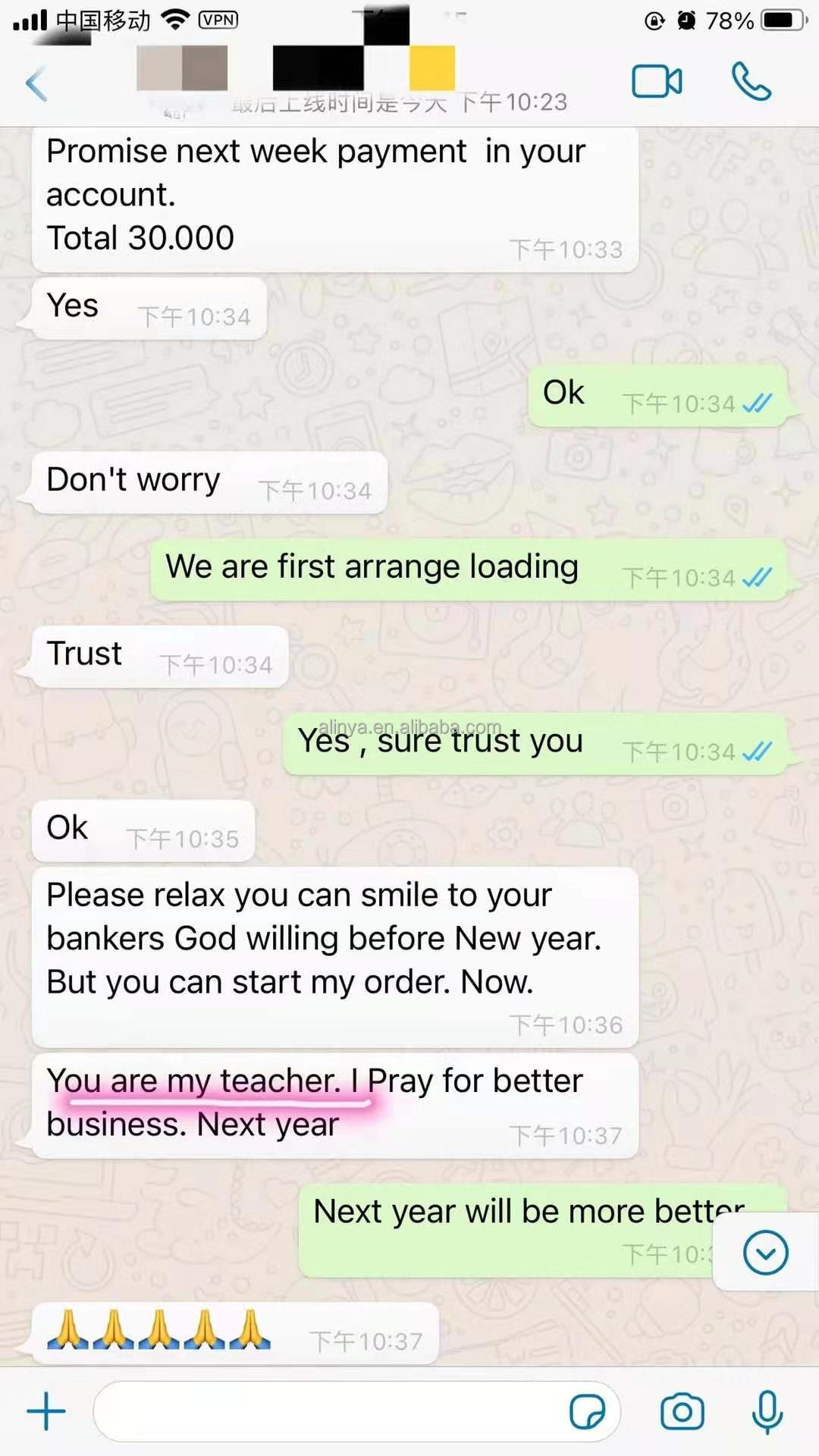

Customer praise:

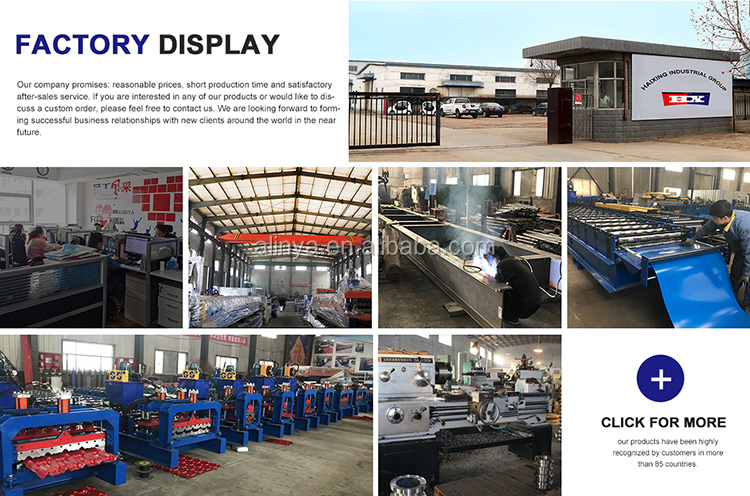

about us!

Tianjin Haixing is a professional cold forming machine manufacturer, we have been focusing on this field for 22 years.Our equipment includes light keel forming machines.

Haixing has a team of engineers with more than 20 years of experience. Meanwhile, our machines use branded electrical components, branded steel mill raw materials, strict process control, two-year warranty, installation and training services.

We have served customers in 85 countries and provide solutions based on your local hot-selling models,Such as Germany, the United States, Mexico, Chile, Bolivia, Italy, Australia, Kuwait, Saudi Arabia, South Korea, Japan, South Africa, Kenya and other 65 countries in different regions. We have extensive experience with the needs of different countries, such as profiles, thickness ranges, usage, installation, etc.

You can rely on our team!

Packaging and Delivery

1). Tighten the container with wire rope and iron 2) Weld the machine with the container. The main forming machine and uncoiler are bare (if you need we can also wrap it in waterproof plastic) 3). PLC control system and motor pump packaged in a waterproof paper covered box

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with professional production team and service awareness, only for exporting all kinds of cold forming machines.

Q: How do you control the precision and quality of the machine?

A: The secret of our production of this precision is that our factory has its own production line, from stamping dies to forming rollers, each mechanical part is independently completed by our factory itself. We strictly control the accuracy of every step from design, processing, assembly to quality control, and we refuse to cut corners.

Q: How long does it take to build this machine?

A: Generally, the machine can be finished within 20 to 45 working days. But if you need a machine urgently, we can save you time.

Q: Is there quality control in the production line?

A: Yes, we have a team responsible for quality control including laying of raw materials, machining of rolls and other parts, machining of roll surfaces and shafts, assembly, testing and packaging.

Q: What is your after-sales service system?

A: We do not hesitate to give you a two-year warranty for the entire line, if the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you need to pay the courier fee yourself. If it exceeds the warranty period, We can negotiate a solution and provide technical support for the entire life cycle of the equipment.

Q: What are your advantages compared to other suppliers?

A: We will provide you with the best service. We will give you good advice beyond your requirements. These lines are easy to install and require low maintenance.

Q: Can we be your overseas agent?

A: Of course, if you have a business in a roll forming line, we would very much welcome your cooperation.

free:

"send"Get free profile drawing and design technical support from our 18-year-experienced technicians below!

VIEW MORE

You may like

-

High speed metal roll forming machine and track

-

c light keel forming frame cad light steel machine

-

House light steel villa light steel keel forming machine

-

Electrical Cabinet Shelf Roll Forming Machine Using Elephant Roll Forming Technology

-

Light steel keel equipment keel rolling forming frame dividing machine

-

metal frame for making drywall drywall, stud rolls, cu shaped light keel forming machine

-

Precast Concrete Fence H Beam Making Machine After Precast Concrete Fence

-

Gypsum Board Ceiling Steel Fur Channel Forming Machine Omega Channel Forming Machine

-

PLC controlled steel CZ purlin roll forming machine for quick replacement

-

XHH C89-5S Lgsf Lgs House Price Keel Weight Lsf Roll Light Gauge Form Steel Frame Machine For House Construction

Other Products

-

$12000.00 - $14500.00 / set

$12000.00 - $14500.00 / set -

$6500.00 - $9850.00 / set

$6500.00 - $9850.00 / set -

$15000.00 - $29000.00 / set

$15000.00 - $29000.00 / set -

$6000.00 - $9000.00 / set

$6000.00 - $9000.00 / set -

$7000.00 - $10500.00 / set

$7000.00 - $10500.00 / set -

$5500.00 - $9800.00 / set

$5500.00 - $9800.00 / set -

$3500.00 - $7500.00 / set

$3500.00 - $7500.00 / set

Related Search

light gauge steel channel roll form machine

light gauge sheet steel roll forming machine

galvanized sheet stud track roll forming machine

steel structural roll forming machine

760 arched color roll forming machine for steel

drywall metal stud and track roll forming machine manufacturer

hot keel channel roll forming machine

floor decking panel roll forming machine

steel flooring deck roll forming machine

steel wheel balancing weight