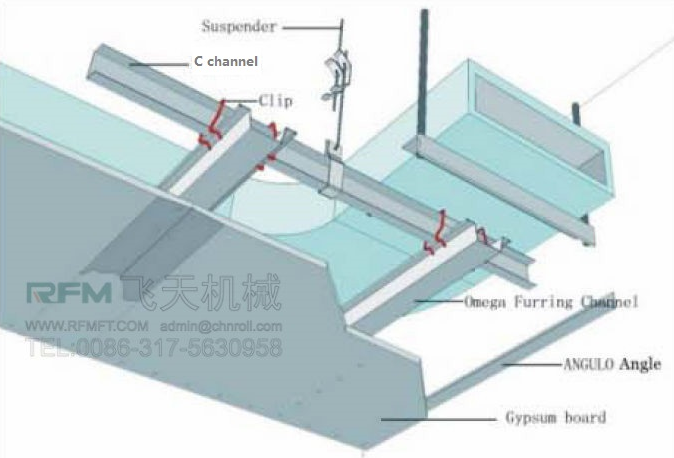

Gypsum Board Ceiling Steel Fur Channel Forming Machine Omega Channel Forming Machine

-

Supplier: Dongguang County Feitian Cold Roll Forming Machinery Co., Ltd. -

Region: Hebei, China -

Contact: Mr Li Xiang -

Price: $7000.00 /set -

Min. Order: 1 set

| Packaging Details: | Host: All rollers are brushed with rust-free oil and packed with waterproof plastic film Control box: Packed with thick cardboard, all parts inside the container will be well fixed with thickened waterproof plastic film on the outside, which can ensure safety and fixation for long-term shipping | Working pressure: | 235---550Mpa |

| product name: | Gypsum board ceiling steel gutter making machine | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,cash |

| port: | Tianjin Xingang, China | Voltage: | 380V, 50Hz, three segments; customized |

| Showroom location: | Egypt, Philippines, Indonesia, Pakistan, India, Mexico, Thailand, Algeria, Malaysia | Main selling point: | long lasting |

| Machine Speed: | Normal: 25m/min; Higher: 40---60m/min | weight: | Kilogram |

| Machine Control System: | Fully automatic PLC control | Mechanical test report: | if |

| Dimensions (L*W*H): | 5.1*0.8*1.5m | Programmable controller brand: | Delta; Siemens; Schneider; Custom |

| Screen Type: | touch screen; text screen | place of origin; place of origin: | Hebei china |

| Machine Color: | shiny blue; grey; milky white; custom | Supply capacity: | 500 sets per year |

| type: | Steel frame purlin machine | Health status: | new |

| Marketing Type: | New Products 2020 | Applicable industries: | Hotels, building materials stores, machinery repair shops, restaurants, household goods, food stores, advertising agencies |

| tolerant: | +/-0.1mm | Transmission type: | gear drive |

| strength: | 5.5kw+4kw | Video external inspection: | if |

| spare parts: | Related tools | brand: | foot |

| Core components: | PLC, engine, motor | Type of machine: | personal arch |

| Production capacity: | 20---40m/min | Core Components Warranty: | 1 year |

| Warranty: | 12 months |

Gypsum Board Ceiling Steel Fur Channel Forming Machine Omega Channel Forming Machine

Gutter forming machine overview

1). In order to design and manufacture the best roll forming machines, we have takenEuropeanQuality Standard;

2). Choose the best materials and components and use our17+ years experience;

3). We achieved twice the machine capacity of our competitors;

4). machineWorking speed up to 60m/min;

5). Very easy to install and operate the roll forming machine.

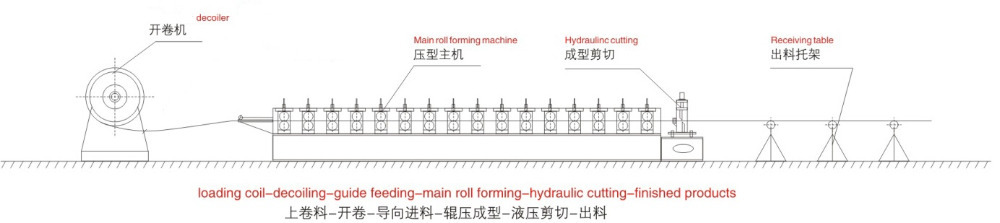

The machine work flow of the gutter forming machine:

Technical parameters of gutter forming machine:

About the raw materials and products of the roll forming machine

|

Materials and Products |

Feed width |

According to the introduction |

|

effective width |

According to the introduction |

|

|

raw materials |

Galvanized Steel Strip |

|

|

thickness |

0.3-0.7mm |

|

|

Yield Strength |

280-350 MPa |

How to load? ? → Uncoiler

|

Manual uncoiler |

Inner diameter: 450-550mm |

Expand by frequency |

|

Outer diameter: 1500mm |

||

|

Maximum coil width: 30 0mm |

||

|

Capacity: 1.5T |

||

|

Uncoiler size: 1.5*1.5*1.5m |

||

|

Uncoiler weight: 355KGS |

||

|

Quantity: 1 set |

||

|

Purpose: Used to support steel coils and unroll them in a turntable manner. Passive uncoiler pulled by roll forming system |

||

What is the main molding machine? ? ? → as follows

|

Host molding machine |

molding step |

12 steps |

|

Shaft diameter |

50mm |

|

|

Machine |

personal arch |

|

|

frame |

Steel plate welding |

|

|

Roller material |

Cr12 |

|

|

Shaft material |

45# steel quenched and tempered |

|

|

Speed of work |

Standard: 20---25m/min; 45---60m/min |

|

|

transportation |

press gear |

|

|

monitor rate |

4kW |

|

|

Voltage |

380V-50HZ-3P (as needed) |

|

|

Machine size |

5.5*0.8*1.5m |

|

|

machine weight |

About 2.5T |

|

|

machine color |

Yellow and blue (as needed) |

|

|

Application: In order to maintain the shape and precision of the product, the welded sheet structure is adopted, Motor reduction drive, chain drive, chrome-plated rollers, can keep The surface of the forming board is smooth, and it is not easy to leave marks when working Features: Ensure stability, accuracy and longevity. |

||

-

High speed metal roll forming machine and track

-

c light keel forming frame cad light steel machine

-

House light steel villa light steel keel forming machine

-

Electrical Cabinet Shelf Roll Forming Machine Using Elephant Roll Forming Technology

-

Light steel keel equipment keel rolling forming frame dividing machine

-

Popular c panel channel steel stud light weight keel equipment roll forming machine

-

metal frame for making drywall drywall, stud rolls, cu shaped light keel forming machine

-

Precast Concrete Fence H Beam Making Machine After Precast Concrete Fence

-

PLC controlled steel CZ purlin roll forming machine for quick replacement

-

XHH C89-5S Lgsf Lgs House Price Keel Weight Lsf Roll Light Gauge Form Steel Frame Machine For House Construction

Other Products

-

$13000.00 / set

$13000.00 / set