High speed metal roll forming machine and track

-

Supplier: Xiamen BMS Group -

Region: Fujian, China -

Contact: Mr Pablo Andrey -

Price: $16980.00 /set -

Min. Order: 1 set

| Forming station: | 12 | Online support: | Online Video Support |

| Tool material: | Cr12Mov tool steel | payment terms: | L/C, Western Union, T/T, MoneyGram |

| Main selling points: | long lasting | Supply capacity: | 30 sets per month |

| Packaging Details: | The main body of the high-speed metal stud and track forming machine is exposed and covered with plastic film (dustproof, anti-corrosion), loaded into a container and firmly fixed in a 1x40GP container suitable for long-distance transportation, and the spare parts are covered with plastic film. | weight: | Kilogram |

| Showroom location: | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile , United Arab Emirates, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Tajikistan, Japan, Malaysia, Australia | Mechanical test report: | if |

| type: | Steel frame purlin machine | Voltage: | AC 3-380V/415V/440V |

| Uncoiler: | Manual/hydraulic optional | Package preview: | |

| output: | About 30-40 meters per minute | Video outbound inspection: | if |

| Marketing Type: | Hot Products of 2019 | Applicable industries: | Hotels, building supplies stores, machinery repair shops, manufacturing plants, food and beverage plants, farms, home use, construction, energy and mining, advertising agencies, roll forming machines |

| Dimensions (L*W*H): | About 9M*2.5M*1.8M | Warranty: | 2 years |

| brand: | battery management system | Work pressure: | 245---550Mpa |

| Core components: | PLC, engine, bearing, gearbox, motor, gear | Working materials: | Galvanized sheet (GI), cold rolled sheet (CRC), hot rolled sheet (HRC) |

| punching: | single and double holes | Origin: | Fujian Province, China |

| strength: | 5.5KW+2KW | Production capacity: | 40-120m/min |

| port: | Xiamen | Core component warranty: | 2 years |

| After-sales service provided: | Engineers available to repair machinery overseas | Health status: | new |

| thickness: | 0.4-1.5 mm | housing: | H400 Beam |

Product Description

High Speed Stud and Track Roll Forming Machine

(One machine with multiple profiles, the interval changes in size)

1. Main features of high-speed stud and track roll forming machine

The advantages of high-speed stud and track machines are as follows:

1. The speed can reach 30-40 meters per minute

2. Increase the hydraulic station to ensure high-speed work

3. Easy to operate and low maintenance cost

4. Beautiful appearance.

5. One machine with multiple profiles, variable size at intervals

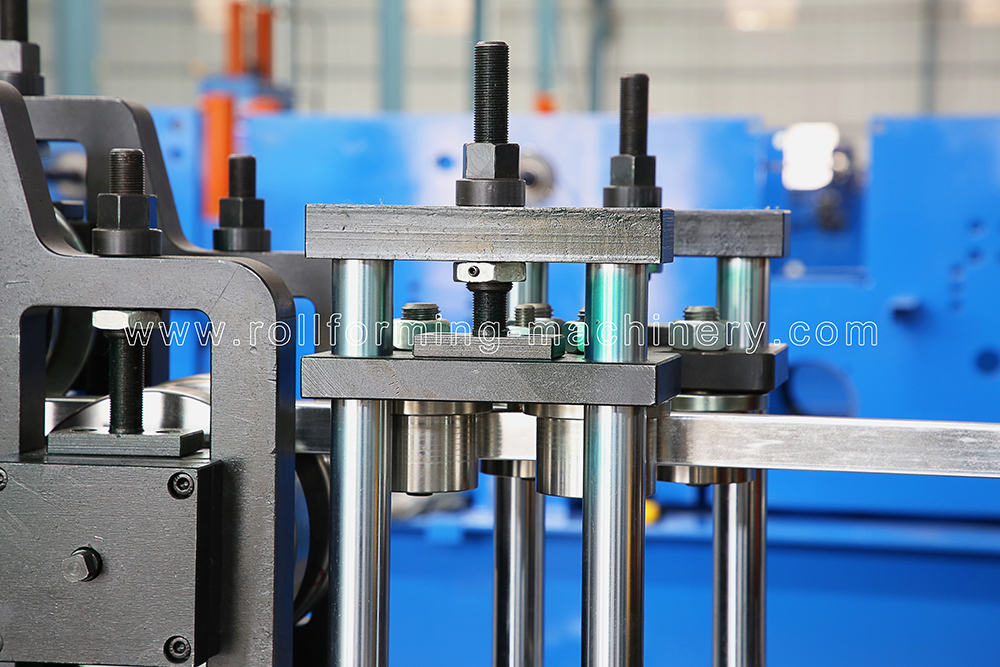

2. Detailed picturesStuds and track rollersForming Machine

Mechanical Parts

1) high speedStuds and TracksMachine tool arc feed guide

brand:battery management systemThe original:China

Arc feeding guide rail (to make feeding smooth and wrinkle-free)

2)High Speed Studs and Tracksmachine drum

brand:battery management systemThe original:China

The roller is made of macro-life die steel Cr12=D3 after heat treatment, CNC lathe,

heat treatment. (Available in black finish or hard chrome finish).

With feeding guide rail, the fuselage frame is welded by 400# H-shaped steel

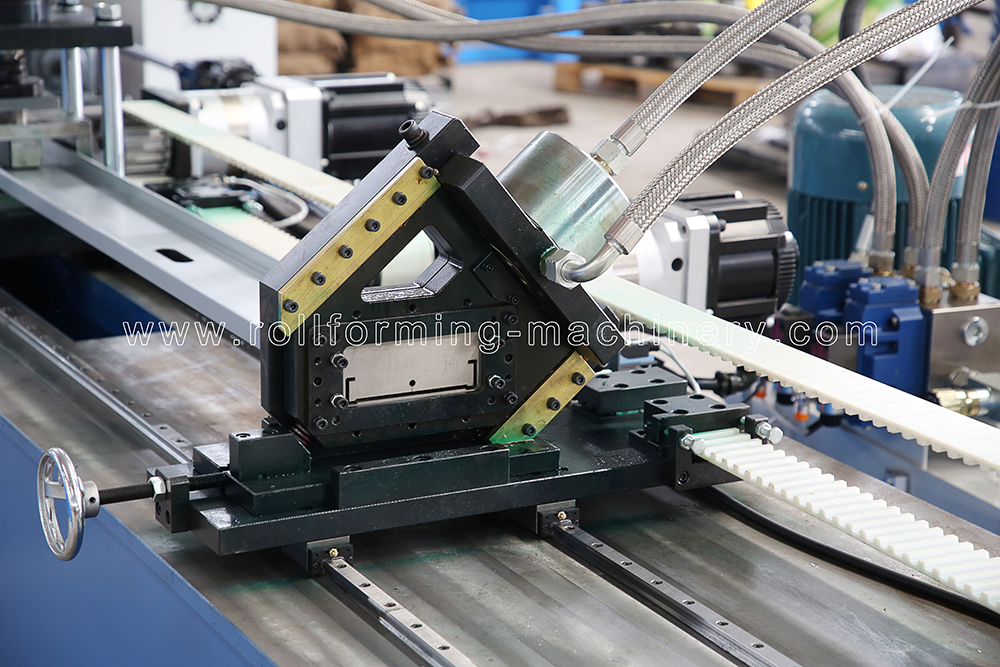

3) Straightening of high-speed studs and track machines

brand:battery management systemThe original:China

4) High-speed stud, orbital machine flying cutting

(One machine with multiple profiles, the interval changes in size)

brand:battery management systemThe original:China

Made of high-quality long-life die steel Cr12Mov after heat treatment

The tool holder is welded by high-quality 30mm steel plate

Hydraulic motor: 5.5KW, hydraulic range: 0-16Mpa

5)High Speed Studs and TracksMachine hydraulic system

brand:battery management systemThe original:China

Enlarging the hydraulic station to ensure high-speed work

6)High Speed Studs and Tracksmachine decoiler

brand:battery management systemThe original:China

Manual uncoiler: one set

Without power, manually control the shrinkage and stop of the inner hole of the steel coil

maximum. Feeding width: 500mm, coil inner diameter range 508mm±30mm

Capacity: Max. 3 tons

Optional 3 ton hydraulic uncoiler

7)High Speed Studs and Tracksexport rack

brand:battery management systemThe original:China

No power supply, 4 meters long, one set

Click here to view the video

High speed other detailsStuds and TracksRoll Forming Machine

Suitable for materials with a thickness of 0.6-1.2mm

The shaft is made of 45# material, the spindle diameter = φ75mm, precision machining

Driven by motor, driven by gear chain, composed of 12 rollers.

Main servo motor = 2.0KW, variable frequency speed regulation. Molding speed is about 30-40m/min

PLC control system (touch screen brand: German Schneider Electric/Taiwan WEINVIEW,

Inverter brand: Finland VOCAN/Taiwan DELTA/ALPHA, encoder brand: Japan Koyo/Omron)

Combination: PLC, inverter, touch screen, encoder, etc.

Cut-to-length tolerance≤±2mm

Control voltage 24V

English User Manual

After-sales serviceStuds and TracksRoll Forming Machine

1. Warranty for Stud, Track Roll Forming Machine

It is one year after the customer receives the machine.

Within one year, we will express the replacement parts to customers free of charge.

2. We provide technical support for the whole life cycle of the machine.

3. We can send technicians to customer's factory to install and train workers, but it will cost extra.

transaction terms

1. Minimum order quantity (MOQ): 1 piece

2. Delivery time: about 45 working days

3. Port of loading: Xiamen Port

4. Payment method: T/T or L/C

5. Export: Australia, UK, Ireland, Mexico, Brazil, Israel, Dubai, Russia, India, Taiwan, Singapore,

Malaysia, Thailand, Philippines, Myanmar, Vietnam, South Africa, Mozambique,

Zambia, Zimbabwe, Nigeria, Egypt, Sudan, etc.

Certification of Automatic Dimension Changing CZ Purlin Forming Machine

company information

company exhibition

Factory Tour

Related Products

C type purlin forming machine

-

c light keel forming frame cad light steel machine

-

House light steel villa light steel keel forming machine

-

Electrical Cabinet Shelf Roll Forming Machine Using Elephant Roll Forming Technology

-

Light steel keel equipment keel rolling forming frame dividing machine

-

Popular c panel channel steel stud light weight keel equipment roll forming machine

-

metal frame for making drywall drywall, stud rolls, cu shaped light keel forming machine

-

Precast Concrete Fence H Beam Making Machine After Precast Concrete Fence

-

Gypsum Board Ceiling Steel Fur Channel Forming Machine Omega Channel Forming Machine

-

PLC controlled steel CZ purlin roll forming machine for quick replacement

-

XHH C89-5S Lgsf Lgs House Price Keel Weight Lsf Roll Light Gauge Form Steel Frame Machine For House Construction

Other Products

-

$39980.00 / set

$39980.00 / set -

$39980.00 / set

$39980.00 / set -

$158000.00 / set

$158000.00 / set -

$32800.00 / set

$32800.00 / set -

$39980.00 / set

$39980.00 / set -

$13900.00 / set

$13900.00 / set -

$10000.00 / set

$10000.00 / set -

$39980.00 / set

$39980.00 / set