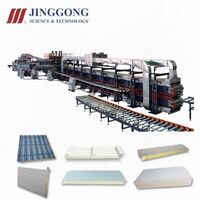

EPS Sandwich Panel Making Machine production Line

-

Supplier: Dongguang County Feitian Cold Roll Forming Machinery Co., Ltd. -

Region: Hebei, China -

Contact: Mr Li Xiang -

Price: $13000.00 /set -

Min. Order: 1 set

| Supply Ability: | 5 Sets per Month; | Warranty: | 1 Year; |

| Marketing Type: | New Product 2020; | sandwich material: | EPS/rock wool/PU/glass wool; |

| Video outgoing-inspection: | Provided; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| glue pump quantity: | 4 sets; | Showroom Location: | Algeria,Malaysia,Egypt,Philippines,Indonesia,Pakistan,India,Mexico,Russia,Thailand; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | the width of stocket board: | 950/1150mm; |

| Name: | EPS Sandwich Panel Making Machine; | Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,CASH; |

| Condition: | New; | Place of Origin: | Hebei, China; |

| Warranty of core components: | 1 Year; | glue way: | Glue pump drops of glue ,adhesive - dripping; |

| Port: | Xingang,Tianjin; | Width of the board: | 1000/1200m; |

| Core Components: | 报警锁; | Applicable Industries: | Hotels,Building Material Shops,Manufacturing Plant,Restaurant,Home Use,Food Shop,Advertising Company; |

| Packaging Detail: | 1. 20'' container 2. The machine we will wrap in plastic and attach marks 3. Other machine elements and tools we have a wood box 4. Before loading, we will fix and check the machine 5. Before shipping, we will invite our customer to check the machine again; | Machinery Test Report: | Provided; |

| Thickness of the material: | 30-300mm; | Local Service Location: | Malaysia,Australia,Morocco,Kenya,Argentina,Chile,Colombia,Algeria,Sri Lanka,Romania,Bangladesh,South Africa,Kazakhstan,Ukraine,Kyrgyzstan,Nigeria,Uzbekistan,Tajikistan,Egypt,Canada,Turkey,France,Viet Nam,Philippines,Brazil,Peru,Saudi Arabia,Indonesia,Pakistan,India,Mexico,Russia,Spain,Thailand; |

| Brand Name: | RFM; | Control System: | PLC; |

| cutting divice: | tracking cutting; |

EPS Sandwich Panel Making Machine

EPS Sandwich Panel Making Machine Profile drawings :

EPS Sandwich Panel Making Machine Process flow :

EPS Sandwich Panel Making Machine parameters :

|

Manual decoiler |

1).Material coil inner diameter: 450mm-550mm 2).Outer diameter:1500mm 2).Max coil width:1250mm 3).Carrying capacity: 5T |

|

Forming device |

1)Shaft material:high grade No.45 steel after treatment 2)Out diameter is80 mm 3)Roller material: 45# steel polished and coated with chrome HRC55-60° 4)Forming speed:8-15m/min 5)Main motor power:3 kw 6)Roller station:16stations 7)Coil width: 1000/1200/1250mm 8)Effective width:950/1150mm 9).Voltage:380v,50Hz,3 phase |

|

Hydraulic cutter |

1). material of blade: Cr12 mould steel with quenched treatment 55-60°C 2). cutting system: adopt advanced hydraulic drive, after forming automatic cut, no distort, no wasting , high safe factor.(main motor stop cutting) |

|

Control system |

1.)Type: PLC Frequency Control System with touch screen 3).Encoder Brand: Omron 4).Screen: Delta test screen 5).Automatic length and quantity measurement 6).Control station is used to control product length and quantity, automatically cutting to length and stop when required quantity is achieved. 7).Length Error: ±2mm, error is easy to adjusted. |

|

Outpur table |

It is simple and used to load finished product. Length:6m |

|

Spare Parts

|

1).Easy damaged parts: conk 2 pcs, fuse-link 4 pcs 2).Rubber mat 1 pcs; 3).Bolt spanner 1 pcs

|

EPS Sandwich Panel Making Machine Photos :

|

Packaging |

Nude and export regular package,any special request as clients’ requested for sandwich panel roll forming machine

|

|

Fixation |

Every part will be fixed by wire and welded before shipping. |

single layer roll forming machine, double layer roll forming machine, glazed tile roll forming machine, purlin roll forming machine, stud and track roll forming machine highway guardrail roll forming machine, door frame roll forming machine,ridge cap roll forming machine, floor deck roll forming machine, EPS Sandwich Panel Making Machine and so on

If you have any questions about Roll Forming Machine , Please feel free to ask me I am Beryl , I will serve for you in 24 hours !

-

CANMAX Manufacturer Construction Engineering High Quality 12m Manual Electric Concrete Pump Spare Parts Mobile Concrete Spreading Arm

-

Prefab Modular House Prefab Prefab House Equipment China 2021

-

China Manufacturer Manufacturing Machine Technology Production Line Guide Rail Telescopic Channel Roll Forming Machine Drawer Slide

-

Earthquake Resistant Precast Concrete House Making Machine, Structural House Equipment

-

160L 280L 350L Tilt Drum Concrete Mixer Mobile Mini Cement Mixer Price

-

Best Selling Roller Shutter Slat Forming Machine / Roller Shutter Door Making Machine

-

Washbasin Pedestal Bathroom Casting Battery Stand

-

modern concrete house machines, fully prefab concrete houses

-

Building materials manufacturing machinery PU sandwich panel machine

-

Price of machine for forming rolls of production line of continuous polyurethane sandwich panels factory customized with ISO9001 / Ce / Sonc

Other Products

-

$7000.00 / set

$7000.00 / set