Zinc Roofing Sheets Price in Nigeria Zinc Roofing Sheets Roll Forming Machine

-

Supplier: Haixing (tianjin) Imp. & Exp. Co., Ltd. -

Region: Tianjin, China -

Contact: Ms Alin Zhao -

Price: $10500.00 / 1 - 2 sets

$9800.00 / 3 - 9 sets

$7500.00 / 10 - 19 sets

$7000.00 / >=20 sets -

Min. Order: 1 set

| Core components: | Pressure Vessels, Motors, Bearings, Gears, Pumps, Gearboxes, Engines, PLCs, Counters | Shaft Material: | 45# steel outer diameter: 70mm |

| Packaging Preview: | payment terms: | L/C,Western Union,D/A,T/T,MoneyGram,paypal | |

| Dimensions (L*W*H): | 6050*1500*1600 | brand: | Huaxin |

| Voltage: | 220V/380V/440V | place of origin; place of origin: | Tianjing, China |

| Core Components Warranty: | 2 years | Material thickness: | 0.3mm-0.8mm |

| Motor brand: | Li Chao | Showroom location: | not any |

| weight: | 5.5 kg | After Warranty Service: | spare parts |

| Feed width: | 1250mm | main motor power: | 5.5kW |

| Rolling thickness: | 0.3-0.8mm | Marketing Type: | New Products 2020 |

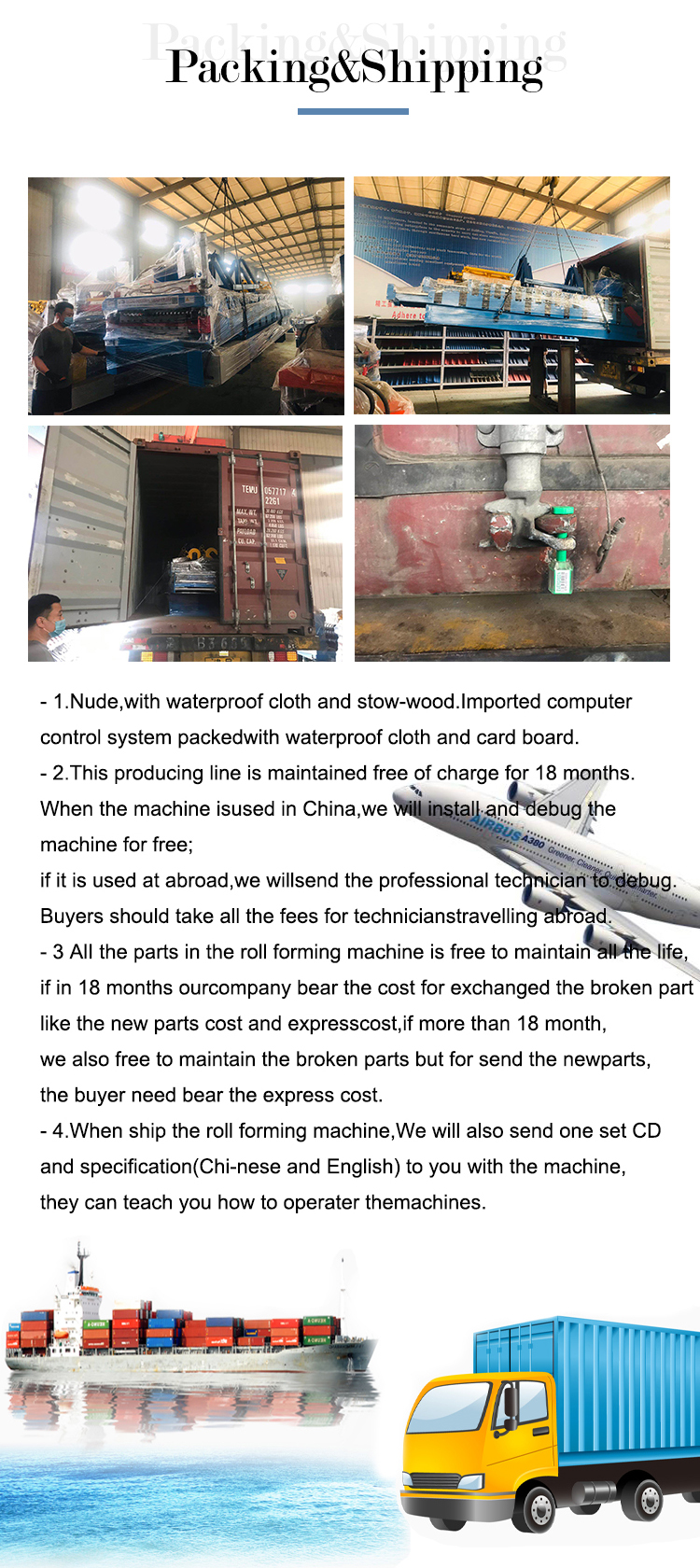

| Packaging Details: | a. The main body of the machine is made of waterproof plastic, and then fixed on the container with steel wire and angle iron with a diameter of 8mm. b. The rollers and shafts are coated with anti-rust oil. c.PLC control system and motor pump are packaged with waterproof paper and plastic film. d. Spare parts in the carton. e. Manual uncoiler is bare packaging. f. The output table is put into the carton. g. If the machine is too long, we divide it into two parts and pack it into one package with steel wire. h. Suitable for shipping. | Mechanical test report: | if |

| Health status: | new | Video external inspection: | if |

| product name: | Sheet in Nigeria Zinc Roof Sheet Roll Forming Machine | type: | Tile forming machine |

| Roller Material: | Cr12 | Production capacity: | 10m/min-15m/min |

| Raw materials: | PPGI PPGL GI GL | Applicable industries: | Building Materials Stores, Manufacturing Plants, Mechanical Repair Shops, Construction Engineering, Energy & Mining |

| Main Frame: | 350H steel | Main selling point: | multifunctional |

| Supply capacity: | 200 sets per month | Warranty: | 2 years |

| port: | Tianjin Qingdao Shanghai Yiwu | Cut Type: | Hydraulic guide post cutting |

| Tile Type: | color steel | use: | roof |

Price of Zinc Roof Sheets in Nigeria Zinc Roof Sheet Roll Forming Machine

Price of Zinc Roof Sheets in Nigeria Zinc Roof Sheet Roll Forming Machine

|

Detailed technical parameters |

|

|

product name |

Price of Zinc Roof Sheets in Nigeria Zinc Roof Sheet Roll Forming Machine |

|

Card |

Huaxin |

|

type |

#HX840 + #HX850 Nigeria Zinc Roofing Sheet Price Zinc Roofing Sheet Forming Machine |

|

Model and raw material |

|

|

substrate |

gastrointestinal tract. General ledger. PPGI. PPGL. aluminum |

|

thickness |

0.3mm-0.8mm |

|

effective width |

840mm+850mm |

|

Details of Roll Forming Machine Components

|

|

| size | 6050*1500*1600mm |

|

weight |

5.5 tons |

|

frame material |

350H steel |

|

Machine side panel |

16mm |

|

color

|

All colors (standard international colors) or (customized) |

|

roller

|

UP: 13rollers DOWN: 15rollers |

|

Roller material |

45# Steel Cr12 Mov HRC 58-62 |

|

Shaft diameter |

Φ70mm |

|

drive mode |

Sprocket and bike chain length: 1 inch |

| productivity |

10-15m/min |

|

Roll forming machine electrical components |

|

|

Voltage |

380V 50Hz three-phase (can be customized according to local voltage) |

|

Motor Power

|

5.5KW Regular brand: Li Chao |

|

Cutting & Hydraulic

|

Hydraulic pump station: 4KW conventional brand: LI CHAO Type: Double guide column hydraulic cutting Blade: Cr12 Mov HRC 58-62 |

|

Control System |

PLC electric control cabinet conventional brand: DELTA |

| Screen | Multilingual key control system Conventional brand: Delta |

| frequency converter

|

Regular brand: Delta |

| feature | Famous brand, multi-purpose machine, easy to operate, fully automatic computer control, long service life |

Nigeria Zinc Roof Sheet Price Zinc Roof Sheet Roll Forming Machine Advantages:

1. Well-known brand, quality is guaranteed.

2.itTwo kinds of profiles can be produced to meet the needs of customers for multiple purposes with less money.

3. Fully automatic computer control, easy to operate.

4. Machine rolls and shafts are produced by precise requirements and controls. The roller material processing method is CR12 MOV heat treatment at 58℃-62℃. Product quality is durable and has a long service life.

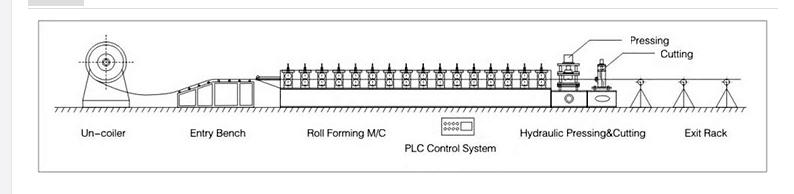

Workflow and Price of Main Components of Zinc Roof Sheet Forming Machine in Nigeria

|

Name: Manual uncoiler

Brand: HX

Purpose: used to support steel coils and unrolled in a rotatable manner. The coils are uncoiled by hand.

Carrying capacity: 5T

Inner diameter: 470mm-530mm |

|

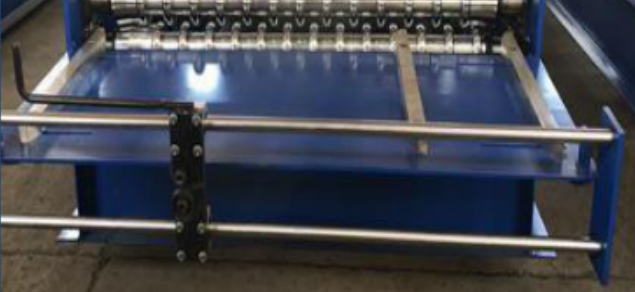

Feeding table:

Feeding table cut by hand.

During the operation of the machine, the raw materials can be cut off in advance at the feeding position to avoid the waste of raw materials.

Sheet metal is manually placed on the feed table. Sheet metal can be smooth and flat |

|

|

|

Roller and Shaft:

Roller material: 45# steel

Drum material processing method: 1. Rough machining 2. Fine polishing 3. Heat treatment 58℃-62℃ 4.Cr12 hard chrome plating

Shaft diameter: 70 mm

The rollers and axles won't scratch the board. It has a long service life and is durable.

|

|

Main motor:

Brand: Lichao

|

|

|

|

Hydraulic pump:

Pump power: 4 KW

Brand: Lichao

Motor with fuel tank pump capacity: 45L

Hydraulic pump station provides cutting power

|

|

Hydraulic cutting:

Blade material: Cr12, heat treatment 58℃-62℃

When the cutting starts, the hydraulic pump station stimulates the guide column to work and drives the blade to cut.

Due to the stable cutting method, the section of the metal plate is neat.

|

|

|

|

PLC electronic control system Brand: DELTA

touch screen electronic panel Brand: DELTA

Multilingual function key design

For setting cutting size, easy operation |

Our products are used in the production of roof and wall construction. Can be used in factories, residences, schools, hotels, shops and other construction sites.

Shipping:

1. will loadA 20/40 foot container.

2. We have professional technicians for loading to ensure that the machine is not damaged.

3. Please provide the nearest port name, we will ask the freight and arrange the shipping for you.

service advantage:

1. Provide engineering drawing design services

2. Provide machine customization service

3. Remote video service

4. Engineer on-site installation service

5. Help customers book delivery services

6. Help customers purchase raw materials services

After-sale service:

1. Payment term: 30% T/T to pay the deposit and the remaining 70% to the buyer after the seller's factory inspection before delivery.

2. Delivery time: We guarantee that the equipment will be ready for shipment within 30 working days after receiving the deposit.

3. After-sale service: If you need, we can send technicians to your country to install the machine. Buyers need to pay all expenses, including: visa, round-trip air tickets, accommodation, salary of 100~120 US dollars per day.

4. Warranty: 2 years

-

Three-layer molding machine

-

Low cost clay brick making machine manual type clay brick making machine suitable for different sizes and different types of bricks

-

1000 type roof panel glazed tile pressing machine

-

HMS900 Electric Tile Cutter with CE Certification 1000mm Cutting Length, Marble Saw

-

Sheet metal building materials manufacturing machinery parts

-

Wall and color steel tile type polyurethane sandwich roof panel manufacturing machine

-

Terrazzo brick press

-

2022 Popular Manual Clay Roof Tile Making Machine Floor Tile Making Machine Roof Floor Tile Press Forming Machine

-

Galvanized floor deck forming machine

-

Automatic metal Ibr shingle trapezoidal shingle roller press machine for sale in South Africa

Other Products

-

$12000.00 - $14500.00 / set

$12000.00 - $14500.00 / set -

$6500.00 - $9850.00 / set

$6500.00 - $9850.00 / set -

$15000.00 - $29000.00 / set

$15000.00 - $29000.00 / set -

$6000.00 - $9000.00 / set

$6000.00 - $9000.00 / set -

$6200.00 - $9500.00 / set

$6200.00 - $9500.00 / set -

$5500.00 - $9800.00 / set

$5500.00 - $9800.00 / set -

$3500.00 - $7500.00 / set

$3500.00 - $7500.00 / set