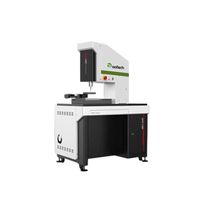

Solar Cell No-Water Non-destructive Laser Dicing Machine

-

Supplier: Wuhan Ooi Photoelectric Technology Co., Ltd. -

Region: Hubei, China -

Contact: Ms Margret Cao -

Price: $80000.00 /unit -

Min. Order: 1 unit

| Showroom Location: | None; | Packaging Detail: | plywood box; |

| Application: | Laser Scribing; | Condition: | New; |

| After-sales Service Provided: | Field installation, commissioning and training; | Laser Type: | Fiber Laser; |

| Video outgoing-inspection: | Provided; | Applicable Material: | Solar cell wafer; |

| Local Service Location: | None; | Graphic Format Supported: | PLT; |

| Marketing Type: | New Product 2020; | Control Software: | Laser scribing software; |

| Place of Origin: | Hubei China; | Laser Source Brand: | SPI/IPG/Behring; |

| After Warranty Service: | Online support; | Brand Name: | Ooitech; |

| Warranty of core components: | 1 Year; | Key Selling Points: | High Productivity; |

| Certification: | ce,ISO; | Warranty: | 1 Year; |

| Single gross weight: | 200.0 KG; | CNC or Not: | Yes; |

| Single package size: | 104X71X171 cm; | Weight (KG): | 5000; |

| Machinery Test Report: | Provided; | Core Components: | PLC; |

| Selling Units: | Single item; | Applicable Industries: | solar panel production line; |

No-Water Non-destructive Laser Dicing machine

Laser cutting solar cell into half piece or 1/3 piece can increase the output of the solar panel power. It can reduce the solar string cell current and reduce the voltage drop loss of the string series resistance. It has been confirmed the significant power gain (2-3%) to the solar panel after cutting the cells into small pieces, Therefore, it is widely concerned and has been pushed into a mass production.

The traditional laser slicing machine currently on the market realizes the function of cell slicing through laser processing and mechanical splitting. It generates dust too much and pollutes the working environment; and cannot avoid the micro cracks caused by the mechanical splitting in the production. , And also reduce the comprehensive bending strength of the solar cell, it will be more risk of cracking for solar cell.

Technical specification

|

Classify |

Item |

Technical index |

Remarks |

|

|

Equipment performance |

Applicable solar cells |

Cell Type |

Bifacial Mono Solar size:156-220mm Half Cut |

reserve the space to update 1/3 1/4 ; less than half hour to switch different sizes solar cells |

|

Cell thickness |

100-200μm |

Maximum thickness deviation of one batch of cells <20μm |

||

|

Cell Grid line layout |

The cutting area of both the front or back side of the cells, must have blank area with width ≥1.5mm (no thick or thin silver grid line) |

|||

|

Cell warpage |

<2mm |

A, B grade cell |

||

|

Maximum capacity (SL5-UD3600) |

3600pcs/h (full cell) |

calculate as 166 perc solar cell |

||

|

Maximum capacity (SL5-UD7000) |

7000pcs/h (full cell) |

|||

|

Equipment utilization |

≥99% |

failure rate ≤1% |

||

|

Fragmentation rate |

≤0.05% |

Including fragments, missing corners, chipped edges and other poor appearance |

||

|

Equipment operation |

Touch screen + regular operation buttons + external wireless keyboard and mouse |

|||

|

Process index |

Heat affected zone |

No |

|

|

|

Comprehensive cutting accuracy |

Centering accuracy ±0.05mm |

|

||

|

Laser index |

Slotting laser |

50W |

SPI/IPG |

|

|

Splitting laser |

200W |

Behring (Delphilaser own brand) |

||

|

Laser wavelength |

1064nm |

|

||

|

cooling method |

Natural cooling |

|

||

|

Laser lifetime |

30,000 hours |

|

||

|

Laser protection |

Level 4 safety protection |

Safety light curtains + optical sealed box +Safety door+ Protective glasses |

||

|

Camera |

Camera |

High resolution industrial camera |

20 million pixels, positioning accuracy ≤±0.05mm |

|

|

Camera light source |

Upper light source + lower backlight |

|

||

|

Loading detect |

Detect the cell chipped edge corner chip |

Take away NG cells |

||

|

Unloading detect optional |

The chipped edges , corner chip, offset of cutting line |

|

||

|

Automatic process |

automatic loading |

Manipulator |

8 feeding boxes, 120 Cells/ boxes |

|

|

Automatic unloading |

Belt + manipulator |

Standard unloading box |

||

|

Splitting ways |

Laser |

Automatic split |

||

|

upgrade |

MES window |

Reserve MES window |

Support multiple data output |

|

Q: Equipment Quality, Reliability Warranty?

1) Every machine in the detection process, through specialized testing equipment and facilities,

before machine out of our factory machine text 24 hours.

2) All of our machines have a 1-year quality Warranty from customers receive the machine. The company has built life-long correspondence files.

Q: Why choose us?

A: Doing business with Ooitech is SAFE and BENEFICIAL. Ooitech qualified Alibaba Trade Assurance

the project, Which means Alibaba will refund if there is any quality problem after your buying.

We are onsite checked by Alibaba. The supplier assessment report can be download on our company

profile site. A reliable supplier ensures the safety of your fund.CE and UL approved machines bring good

quality, and reasonable price helps you make profits from our machine.

Q: Do you have Training to Customer?

A: We will supply the machine operation manual in the English version.

For installation and operation, including introduction for the composing of equipment, working

principle of equipment, common knowledge of computers, controlling principle of electric devices,

daily maintenance measures of equipment. Personal demonstration for installation and adjusting

of equipment, operation of equipment, programming of the computer.

Users can dispatch representatives to our factory for 2-3 days for training. We are responsible for

training them free of charge. While all the charges including traveling charges and accommodation

will be afforded by the user.

Q: What are your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

More details of No-Water Non-destructive Laser Dicing Machine, contact whatsapp:+8613554255933

-

Perfect Semiconductor Wafer Laser Marking Machine with Laser-20W

-

Perfect Laser - High Quality 20/50W Silicon Wafer Cell Fiber Laser Scribe Cutting Machine for Solar PV

-

Ooitech 20w fiber laser scribing machine solar cell laser cutting machine for crystal solar cell cutting

-

Wafer Slicer Wafer Slicer Wafer Saw

-

Laser irradiating solar cell engraving machine

-

Silicon Wafer Photovoltaic Solar Cell Laser Cutting Machine, With Sorting Function, Can Be Customized

-

Solar Cell Laser Scribing Machine Solar Equipment

-

Fiber laser cutting machine with solar cells

-

High-speed automatic solar cell laser dicing machine

-

High quality solar cell laser scribing machine, factory price

Other Products

-

$8000.00 / unit

$8000.00 / unit -

$80000.00 / unit

$80000.00 / unit -

$80000.00 / unit

$80000.00 / unit -

$8000.00 / unit

$8000.00 / unit -

$10000.00 / unit

$10000.00 / unit