8 Color Computerized cylinder engraving gravure printing machine For Pvc Shrink Bopp Pet Paper

-

Supplier: Shanghai Printyoung International Industry Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Wendy Wen -

Price: $5000.00 /set -

Min. Order: 1 set

| Place of Origin: | Zhejiang China; | Port: | shanghai; |

| Applicable Industries: | Printing Shops; | Rewinding tension: | 40N/m; |

| Type: | Rotogravure Printing Machine; | Certification: | CE Certification; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Printing speed: | 120 m/min; |

| Main motor: | 11kw; | Packaging Detail: | Standard export packing; |

| Condition: | New; | After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service; |

| Diameter Of Unwind / Rewind: | 600mm; | Brand Name: | Printyoung; |

| Weight: | 15000kg; | Register Precision: | Vertical ± 0.1mm; |

| Warranty: | 1 Year; | Automatic Grade: | Automatic; |

| Dimensions(L*W*H): | 16400*3200*3020mm; | Printing width: | 1100mm; |

| Color & Page: | Multicolor; | Diameter of printing cylinder: | 100mm-350mm; |

| Supply Ability: | 1 Set/Sets per Month; | Usage: | Bill Printer,Card Printer,Cloths Printer,Label Printer,Paper Printer; |

| Payment Terms: | L/C,D/P,T/T,Western Union; | Print Material: | BOPP PET PVC PC Paper; |

| Printing colors: | 8 colors; | Voltage: | 380V / 220V; |

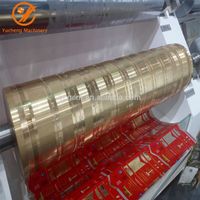

8 Color Computerized Rotogravure Printing Machine For Pvc Shrink Bopp Pet Paper

The machine is used for bopp , pet , pvc ,cpp , pc , the same nature complex film and paper . Its printing speed is 80-100m/min, while the mechanical speed is 120m/min.The machine adopts air cylinder, pulling the core shaft to install the plate.The drying is equipped with the centrifugal fan on the external frame to blow the absorption of heat recycling wind system and the tempeature is controlled by intelligent temperature controller to save electricity and strengthen the drying function.

Printing material available:

PET: 12-100μm

PE: 35-100μm

BOPP: 15-100 μm

CPP: 20-100 μm

PVC:20-100μm

Paper:20-120gsm

Note: And other film materials with the similar printing performance listed above.

Main Features

1 Unwind unit

(1) Inside dual station turret with 600mm diameter for plastic film, inching rotation.

Outside single station turret with 1200mm diameter for paper.

(2) For inside dual station turret, two unwinding shafts are transmitted by powder brake, when change the roll, no need to slow down the speed or stop the machine.

For outside single station turret, unwinding shaft is transmitted by powder brake, when change the roll, you need to stop the machine.

(3) Adopt with magnetic powder tension

(4) Horizontal adjustment of printing material manually

(5) Air shaft

2 In-feed unit

(1) Double roller rolling type, combined with steel roller and rubber roller.

(2) Pneumatic rubber roller control

(3) In-feed roller is controlled by magnetic powder brake and automatic tension controller.

3 Printing unit

3.1 Printing pressure structure

(1) Pneumatic pressing roller Φ110mm, PU rubber.

(2) Cylinder installation: Shaftless type; pneumatic

(3) Max.length of the printing cylinder: 820mm

(4) Distance between each unit: 1000mm.

(5) Automatic computerized registration, video inspection system.

3.2 Doctor blade

(1) Pneumatic movement, controlled by two air cylinder,driven by independent synchronous motor.

(2) The horizontal direction, vertical direction and its angle can be adjusted

(3) The movement of the doctor blade: ±5mm

3.3 Ink plate

(1) Ink plate up and down in vertical direction, adjusted by handwheel.

(2) Printing cylinder directly dipped into the ink plate.

(3) The max. depth of the printing cylinder dipped into the ink: 40mm.

(4) Ink plate: made of stainless steel.

3.4 Ink recycle system

Each printing unit has one pneumatic ink pump.

4. Drying part

(1) Each unit has a separating drying system.

(2) Sealed oven type which saves energy.

(3) Drying method: Electric heating.

(4) Intelligent continual constant temperature controlling

(5) Blower: centrifugal blower

(6) Max oven temperature: 80℃

(7) Oven length: 1000mm

(8) Intake blower power: 1.5KW

Outtake blower power: 1.1KW

(9) Independent drying and suction exhausting system, air circulated, max recycled rate 50%.

(10) Outside oven increase the amount of blowing air to ensure the drying.

(11) Waste air eliminating tunnel.

(12) Assisted oven on the top of last printing unit can prevent the last color adhesive to the printing cylinder when the color cover the whole cylinder, making the film completely dry.

(13) Pre-heating system for paper before printing.

(14) For gas heating, we will install heat converter, solenoid valve and gas pipe on the machine, you need to prepare a boiler to produce gas.

5. Cooling part

(1) Centrifugal blower cooling device 0.25KW

6. Out-feed unit

(1) Double roller rolling type, combined with steel roller and rubber roller.

(2) Pneumatic rubber roller control

(3) Out-feed roller is driven by torque motor.

7. Rewind part

(1) Inside dual station turret with 600mm diameter for plastic film, inching rotation.

Outside single station turret with 1200mm diameter for paper.

(2) Two rewinding shafts are transmitted by two torque motor, two torque motor independently control rewinding shaft can ensure the same line speed of rolls during roll replacement under high speed running, and buffering the film impacting, reduce film waste, save time and improve efficiency.

(3) Air shaft

(4) The horizontal movement of material is manual.

-

Rotogravure printing machine 2 4 6 colors biodegradable plastic film

-

Wallpaper production equipment Non-woven wallpaper gravure printing line Cloth wallpaper embossing line

-

Cigarette paper engraving machine

-

Second-hand 8-color drop-roll gravure printing machine

-

Flexo ink proofer for gravure and flexo printing factories

-

Gravure printing machine 9 color cigarette case tipping paper printing machine

-

Rotogravure printing machine 8 colors price printing machine plastic rotogravure printing machine

-

mini rotogravure printing machine

-

Two-color gravure printing machine ASY-2800

-

LDPE printer printing PE rotogravure with 6 colors gravure printing machine shop bag with good quality

Other Products

-

$45000.00 / set

$45000.00 / set -

$5000.00 / set

$5000.00 / set -

$13000.00 / set

$13000.00 / set -

$19500.00 / set

$19500.00 / set -

$7000.00 / set

$7000.00 / set -

$18000.00 / set

$18000.00 / set -

$45000.00 / set

$45000.00 / set -

$45000.00 / set

$45000.00 / set -

$45000.00 / set

$45000.00 / set -

$20000.00 / set

$20000.00 / set