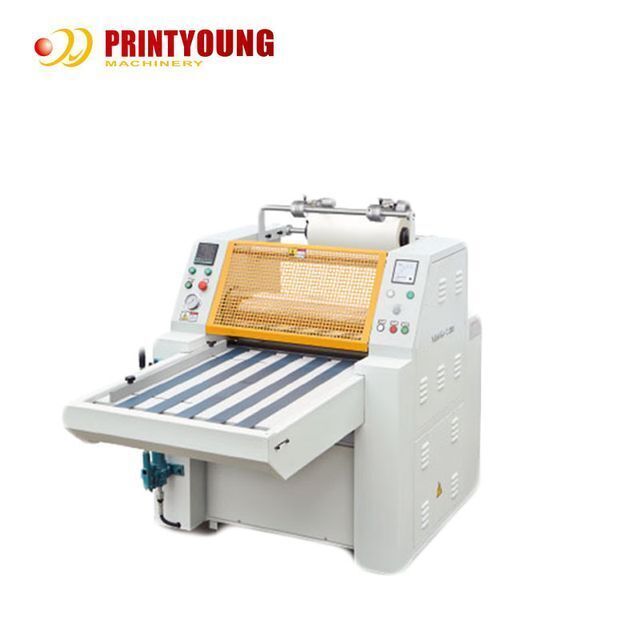

YDFM-920 Manual Hot Roll Bopp Thermal High Speed Plastic Film Laminating Machine for Paper Book Magazine Poster and Postcard

-

Supplier: Shanghai Printyoung International Industry Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Wendy Wen -

Price: $5000.00 /set -

Min. Order: 1 set

Product details

| Packaging Detail: | Roll packing with plastic bag outside or customized.wooden case each paper cutting machine; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Laminating Speed: | 0-30m/min; | Weight: | 520kg; |

| Voltage: | 380v; | Payment Terms: | L/C,T/T; |

| Place of Origin: | China; | Type: | Laminating Machine; |

| Key Selling Points: | High-accuracy; | Port: | Shanghai or Ningbo; |

| Paper Thickness: | 105-500g/m2; | Driven Type: | Mechanical; |

| Max Paper Width: | 800mm; | Warranty of core components: | 1 Year; |

| Application: | Food,Commodity,Medical,Chemical; | Overall Dimensions: | 1900x1500x1600mm; |

| Warranty: | 1 Year; | Brand Name: | PRINTYOUNG; |

| Packaging Material: | Paper; | Packaging Type: | Cartons; |

| Showroom Location: | Egypt,Italy,Saudi Arabia,Mexico,Morocco,Algeria,South Africa; | Video outgoing-inspection: | Provided; |

| Dimension(L*W*H): | 1900x1500x1600mm; | Gross Power: | 8kw; |

| Condition: | New; | Total Weight: | 520kg; |

| Supply Ability: | 50 Tons per Month; | Machinery Test Report: | Provided; |

| Local Service Location: | Egypt,Italy,Saudi Arabia,Mexico,Morocco,Algeria,South Africa; | After-sales Service Provided: | Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; |

| Certification: | CE; | Model: | YDFM-920; |

| Applicable Industries: | Hotels,Garment Shops,Food & Beverage Factory,Restaurant,Advertising Company; | Package Preview: | ; |

| Marketing Type: | New Product 2020; | Core Components: | PLC,Engine,Bearing,Gearbox,Motor; |

| Automatic Grade: | Manual; |

Products Description

YDFM-920 Automatic hot melt plastic thermal film

laminating machine

YDFM series of hydraulic laminating machine is compact and economic laminator. It adopts the designs of manual feeding, manual hydraulic pressuring system, automatic lamination and auto paper winding. Laminated paper shall be cut by manual work. The reasonable structure saves the occupation of floor area so much. Manual hydraulic pressuring system provides big pressure to guarantee good laminating quality. Excellent laminating performance solves completely the problem of snowflake spots in traditional lamination, and perfects products quality and also reduces users’ production costs so much. So this type of laminator is a wonderful choice for laminating process to medium and small enterprises.

Technical Parameters

YDFM-920 Film Laminator Machine | ||

Model No. | YDFM-920 | |

Max Paper Size | 800mm | |

Paper Thickness | 105-500g/m2 | |

Laminating Speed | 0-30m/min | |

Gross Power | 8kw | |

Total Weight | 520kg | |

OverallDimensions | 1900x1500x1600mm | |

It suits for pre-coated film, and it is widely used for magazines, paper, books and packs for food, medicine, cosmetic and so on.

Company Profile

Why Choose Us

Packaging&Shipping

Q1: Are you a manufacturer or a trading company?

A: Our shanghai office is mainly doing export. We have our own factory in Wenzhou, Zhejiang Province.

Q2. What is the machine warranty?

A: One year. After the warranty, we still provide technical support to buyer at low cost.

Q3. What is the production time while placing order?

A: Normally about 10-20 days.

Q4. What is the delivery time?

A: 15-30days after deposit.

Q5. Can your company handle shipping for customers?

A: Yes, just give us destination sea port or container yard.

Q6. Does the packing strong?

A: Yes. Adopts moisture-proof and shock-proof packaging which is suitable for long-distance road transportation and various types of weather conditions. A full set of maintenance and operation manuals is included..

Q7. How about the machine installation and training ?

A: 1)We provide training in our factory for free;

2)We can send technicians (engineers) to your factory for installation and training. You shall pay the round trip air fare and accommodations, plus each technician charges USD100/per day.

Q8. Do you have machines in stock?

A: For standard model, we have a large quantity in stock. For special model, we need 20-30 days to produce it for you.

Q9. How can you assure the machines’ quality?

A: Each machine will be test running at least 24 hours before delivery to assure the quality. And during the warranty, we will give spare parts for free if machine has any problem.

Q10. Do you inspect machines or test running before packing?

A: Of course we do. We have QC department to debug the machine before packing. If you want to use specific material to do the test running, you need to pay for the cost of the material

Q11. What’s the payment term?

A: T/T 50% in advance, the balance shall be paid before delivery. We also accept payment by West Union or L/C at sight.

Q12. Do you accept factory visiting?

A: Warmly welcome for your visiting.

Q13. How many years are you in printing field?

A: Shanghai company is 12 years old, the factory is more than 20years.

Q14. How many clients do you have?

A: We have sold our machines to about 60 countries. We have agents in South Africa, Morocco and Italy.

VIEW MORE

You may like

-

EC-650 Economical and practical electric semi-automatic cold laminating machine

-

High quality RFID chip card making machine

-

Fayon 1600DA 160cm Automatic High Speed Cold Laminator Roll Laminating Machine Cold Laminator

-

Hangzhou Befitter HT-650 650mm 25" Automatic Hot Foil Transfer Laminator

-

Cheap price large format fayon smart workbench 1325 flat laminator workbench flat laminating machine flat laminating machine

-

SWFM520C 485mm fast hydraulic manual paper feeding automatic cutting and laminating machine 0-25m/min

-

L0 Wide Format Smart FY916 Manual Cold Flat Laminator

-

Hot selling double-sided adjustable speed manual a2 a3 hot and cold laminating machine laminating machine price

-

Automatic roll laminator/Automatic roll laminating machine

-

L388 automatic roll to roll roller laminating machine with metal roller paper hot roll laminating machine for printing shop

Other Products

-

$45000.00 / set

$45000.00 / set -

$13000.00 / set

$13000.00 / set -

$19500.00 / set

$19500.00 / set -

$7000.00 / set

$7000.00 / set -

$18000.00 / set

$18000.00 / set -

$45000.00 / set

$45000.00 / set -

$45000.00 / set

$45000.00 / set -

$45000.00 / set

$45000.00 / set -

$20000.00 / set

$20000.00 / set -

$11000.00 / set

$11000.00 / set

Related Search

high spe plastic film bag machin suppliers

automatic bopp film lamination machine

high speed plastic bag continuous sealer

automatic high speed t shirt bag machine

high quality plastic injection moulding machine

bopp film lamination machine printing suppliers

coil hot rolled steel

ce hot rolled u channel

3 roll manual plate rolling machine suppliers

hot rolling machine suppliers