LDPE printer printing PE rotogravure with 6 colors gravure printing machine shop bag with good quality

-

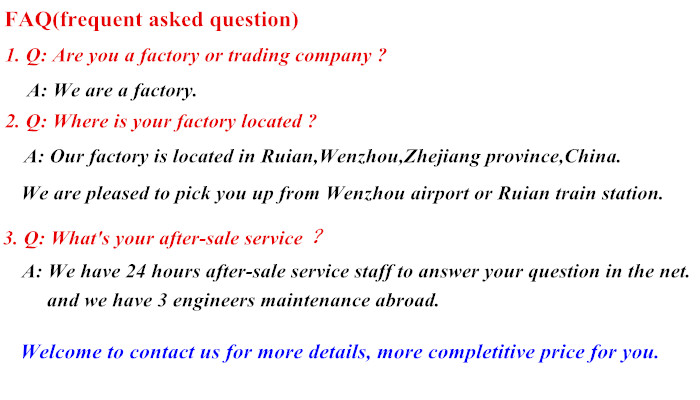

Supplier: Wenzhou Qiangda Printing Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Mero Liu -

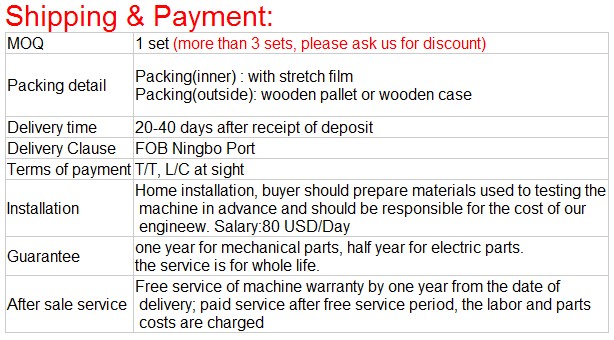

Price: $200000.00 /set -

Min. Order: 1 set

| Certification: | CE, ISO9001 | Local service location: | not any |

| weight: | 30 tons | place of origin; place of origin: | Zhejiang, China |

| Applicable industries: | Flexible packaging, thermal transfer, PE, LDPE printers | payment terms: | L/C, T/T, MoneyGram |

| Supply capacity: | 20 sets per quarter | servo motor: | Each printing unit is driven by a servo motor |

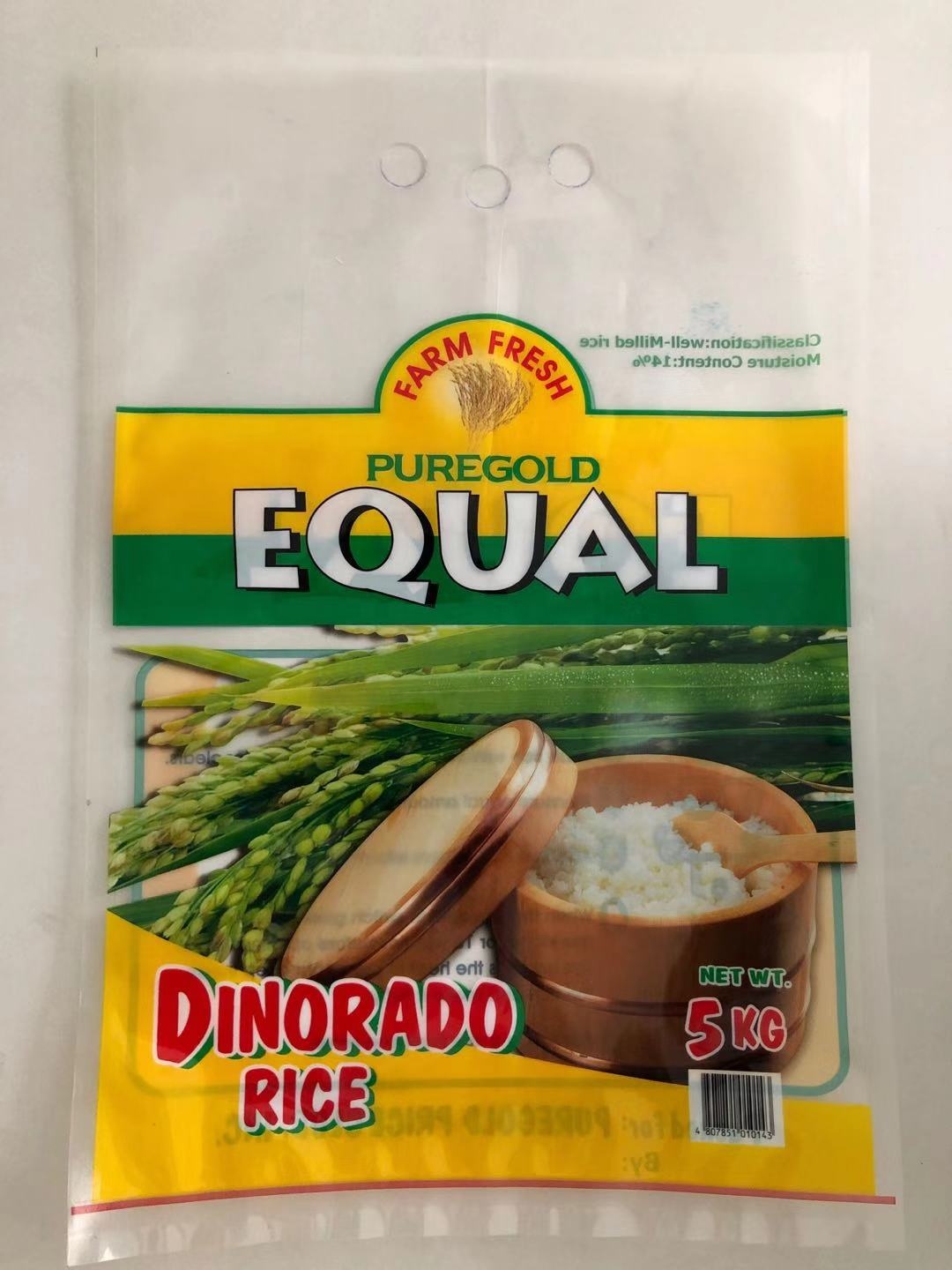

| Card: | Siemens servo motor | Package preview: | |

| Control System: | Electronic spool tension control system | Health status: | new |

| type: | Gravure printing machine | After-sales service provided: | Online support, on-site installation, commissioning and training, on-site maintenance and repair services |

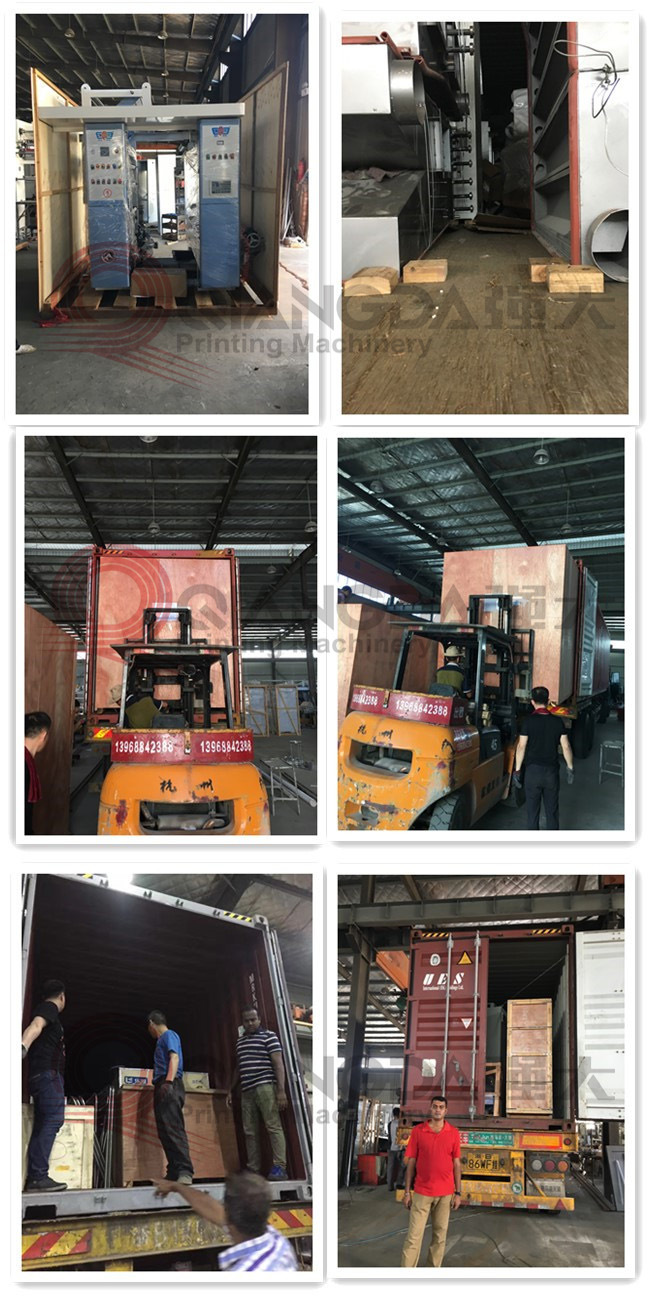

| Colors and Pages: | Polychromatic | Packaging Details: | Stretch film packaging |

| After warranty service: | Video technical support, online support, spare parts | usage: | PE printer |

| Core component warranty: | 1 year | Main selling points: | high accuracy |

| Showroom location: | not any | Core components: | PLC, gearbox, motor |

| Warranty: | 1 year | Voltage: | Three-phase 380V 50HZ |

| brand: | strong | port: | Ningbo |

| Marketing Type: | 2019 Hot Products | Automatic level: | automatic |

| Video shipment inspection: | if | Mechanical test report: | if |

| drive: | Siemens servo motor drive | Dimensions (L*W*H): | 15m x 4m x 4m |

| accuracy: | 0.06mm |

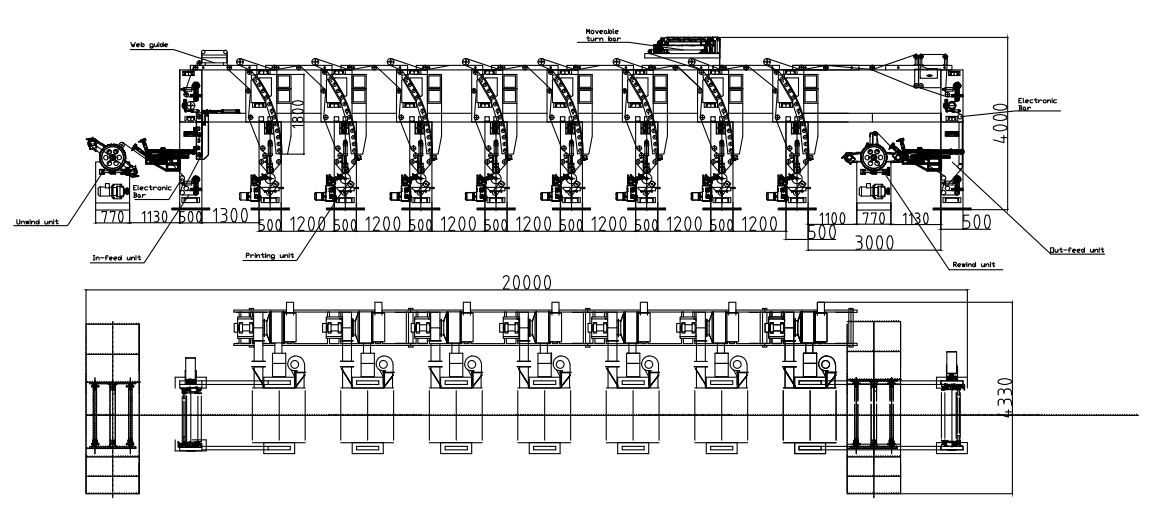

QHSY-A type ELS type 1050mm 8-color gravure printing machine

Layout

use

This machine is suitable for multi-color continuous printing of roll materials with good printing performance such as cigarette packs, cork paper, liquid cartons, BOPP, CPP, PET, PVC, PE, NYLON and other similar film materials.

feature

- This machine isGerman Siemens electronic transmission shaft tension control system.

- This machine can be used simultaneouslywater-based inkandSolvent Ink.

-Fully enclosed structure, to realize the factory workshopodorless pollution.

- Maximum. mechanical speed320 m/min, to the maximum. printing speed300m/min.

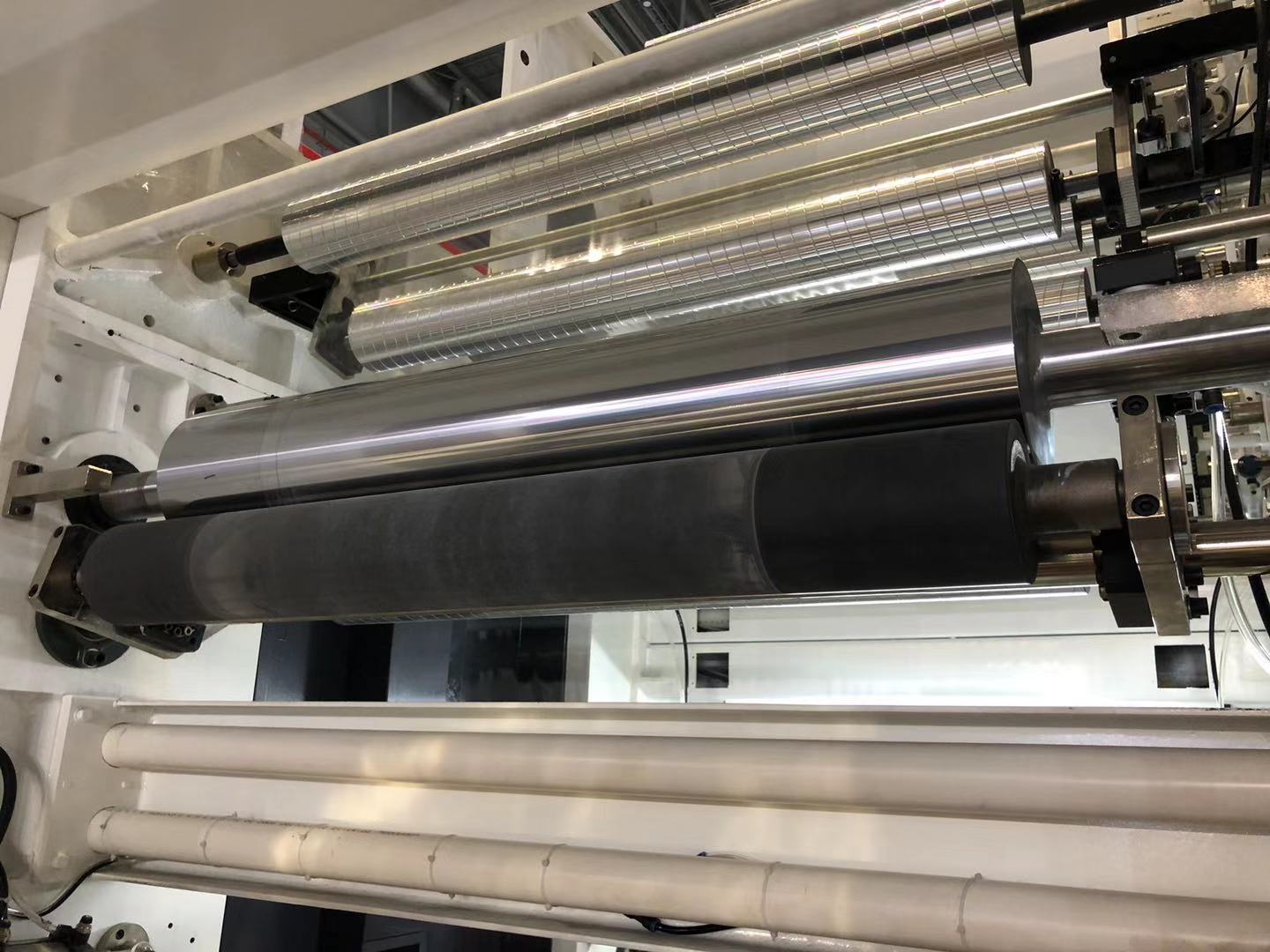

- Separate double-station rotary on both sidesturret, to the maximum. Unwinder and Winder Diameter:Φ800mm

- unwinding and rewinding unitShaftless Pneumatic ConeNetwork loading and unloading.

-automaticstitchingnon-stop (automatic changer)

-vertical&horizontalAutomatic registration control system with video detection, precision:±0.06mm

-pre-registration systemEnsures easy registration and reduces material waste at machine start-up.

- Ink transfer roller technology makes ink transfer more uniform for better printing quality, and the machine can run at high speed without ink flying.

- The printing unit consists ofSiemens servo motor,1 color 1 Siemens servo motor.

- The feeding and discharging device consists ofSiemens servo motor.

-ShaftlessPneumatic cone topping.

-cassetteHeavy-duty scraper construction.

- internal dryerStainless steelstructure to prevent rust.

-static eliminationFor the feed unit and rewind unit,Static brushprinting unit.

printing material

|

OPP |

15-60um |

pvc |

20-65um |

|

BOPP |

15-60um |

Nylon membrane |

15-50um |

|

CPP |

15-60um |

polyethylene |

30-100um |

|

pet |

12-60um |

Paper |

30-80 grams |

maintechnical parameter

|

print order |

from left to right |

|

Printing color number |

8 colors |

|

maximum. Printing cylinder loading width |

1100mm |

|

Guide roller width |

1050mm |

|

maximum. Effective printing width |

1000mm |

|

machine inner width |

1400mm |

|

Plate cylinder diameter |

Φ120mm-Φ300mm |

|

mechanical speed |

320m/min |

|

printing speed |

300m/min |

|

accuracy of registration |

vertical≤±0.06mm(automatic chromatography; depending on material) |

|

side≤±0.10mm(automatic chromatography; depending on material) |

|

|

maximum. Unwinding diameter |

Φ800mm |

|

maximum. Rewinder Diameter |

Φ800mm |

|

Core diameter |

Φ76mm x Φ152mm (3 inch & 6 inch) |

|

Tension Control Range/Accuracy |

3~30kgf/±0.5kgf |

|

maximum. Embossing roller pressure |

600kgf |

|

Embossing roller hardness |

Shore hardness (A) 70°~75° |

|

scraper movement |

±5mm |

|

Oven length |

1.9 m (2.9 meters above the final printing unit above the dryer) |

|

maximum. drying temperature |

80℃(room temperature 20°C) |

|

Temperature control accuracy |

±2℃ |

|

maximum. Oven speed |

30 m/s |

|

Maximum air volume |

5800 meters3/H |

|

Hot air return utilization rate |

0~50% |

|

Fan power |

4KW (Fan power of the final printing unit is 5.5KW) |

|

Unwinding servo motor |

5.5 kW (Foton servo motor) |

|

Winding servo motor |

5.5 kW (Foton servo motor) |

|

Feed servo motor |

3.5 kW (Siemens servo motor) |

|

Discharge servo motor |

3.5 kW (Siemens servo motor) |

|

Servo motor power |

5 kW x 8 (Siemens servo motor) |

|

heating power |

288 kW (36 kW x 8) |

|

total power consumption |

about 390 kW |

|

current power consumption heating by natural gas or steam |

about 100 kW |

|

Voltage |

3-phase X 380V X 50HZ±10%, with ground wire and neutral wire |

|

Air consumption |

0.8 meters3/H |

|

Air consumption |

0.6Mpa≤P≤1.0Mpa |

|

chilled water flow |

8 meters3/H |

|

gross weight |

about 40Ton |

|

Dimensions |

about20000(large)x4400(width)x4000(hours)mm |

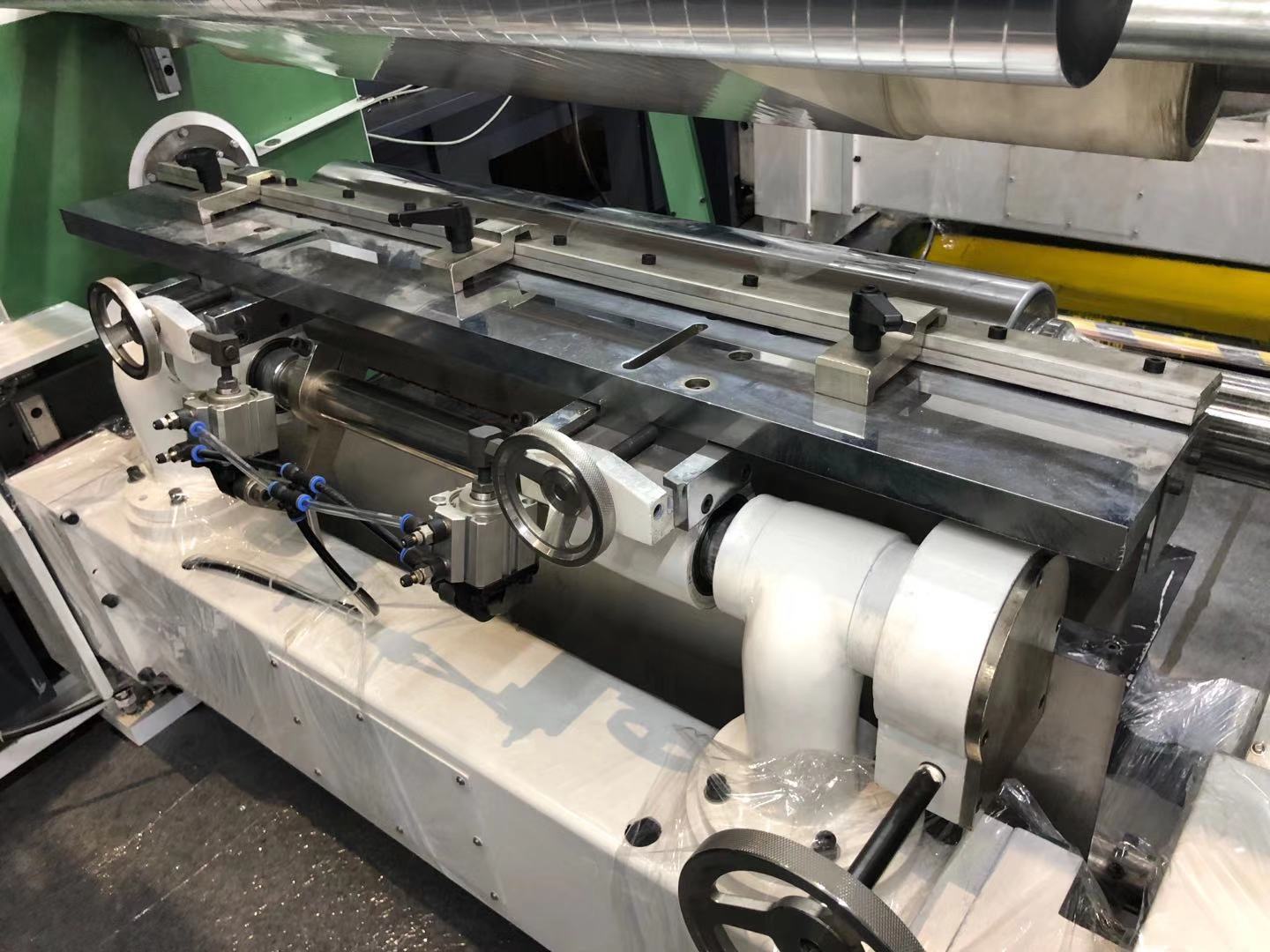

Relax

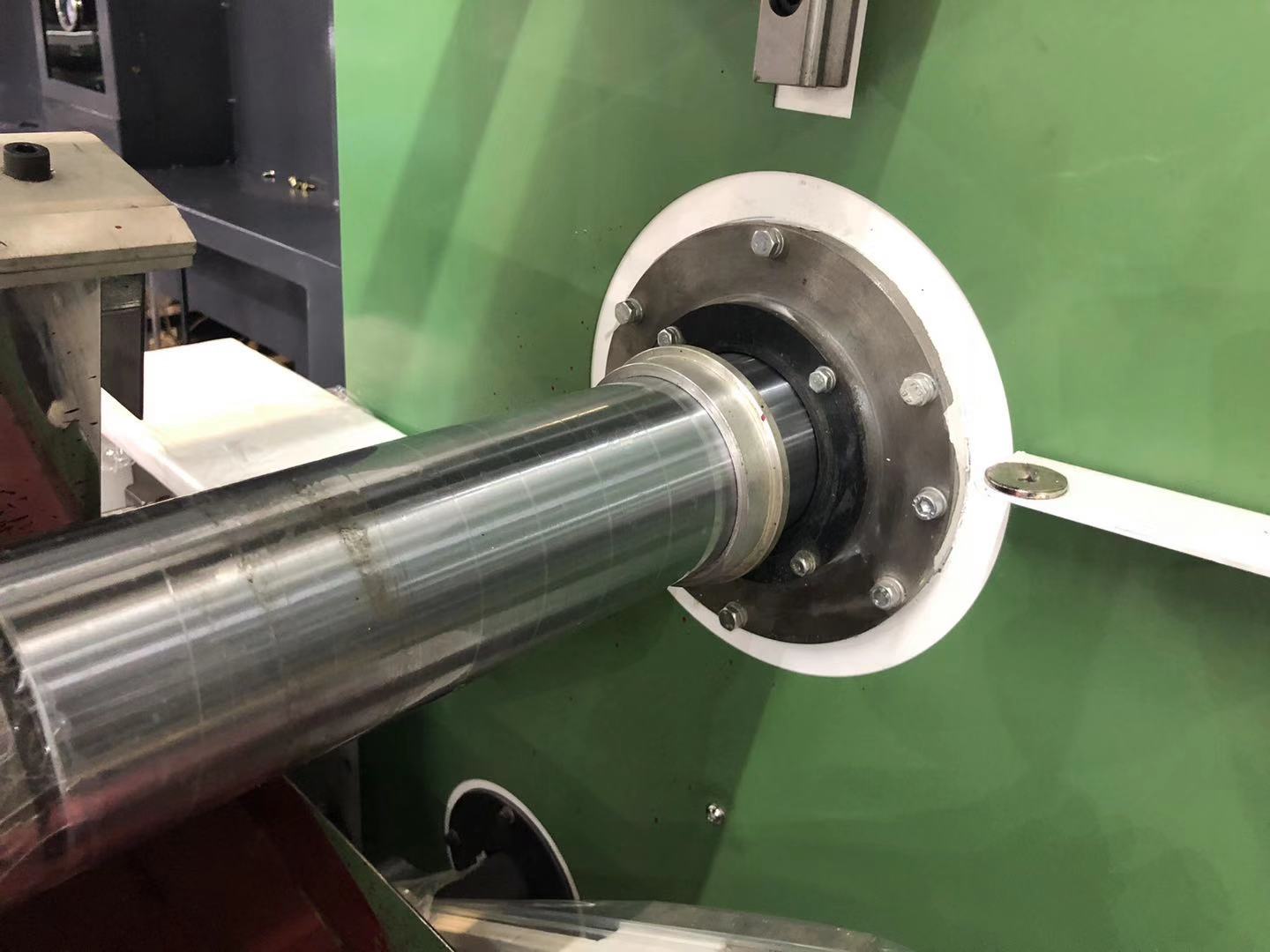

dance roller

scraper

Spindle head

printing unit

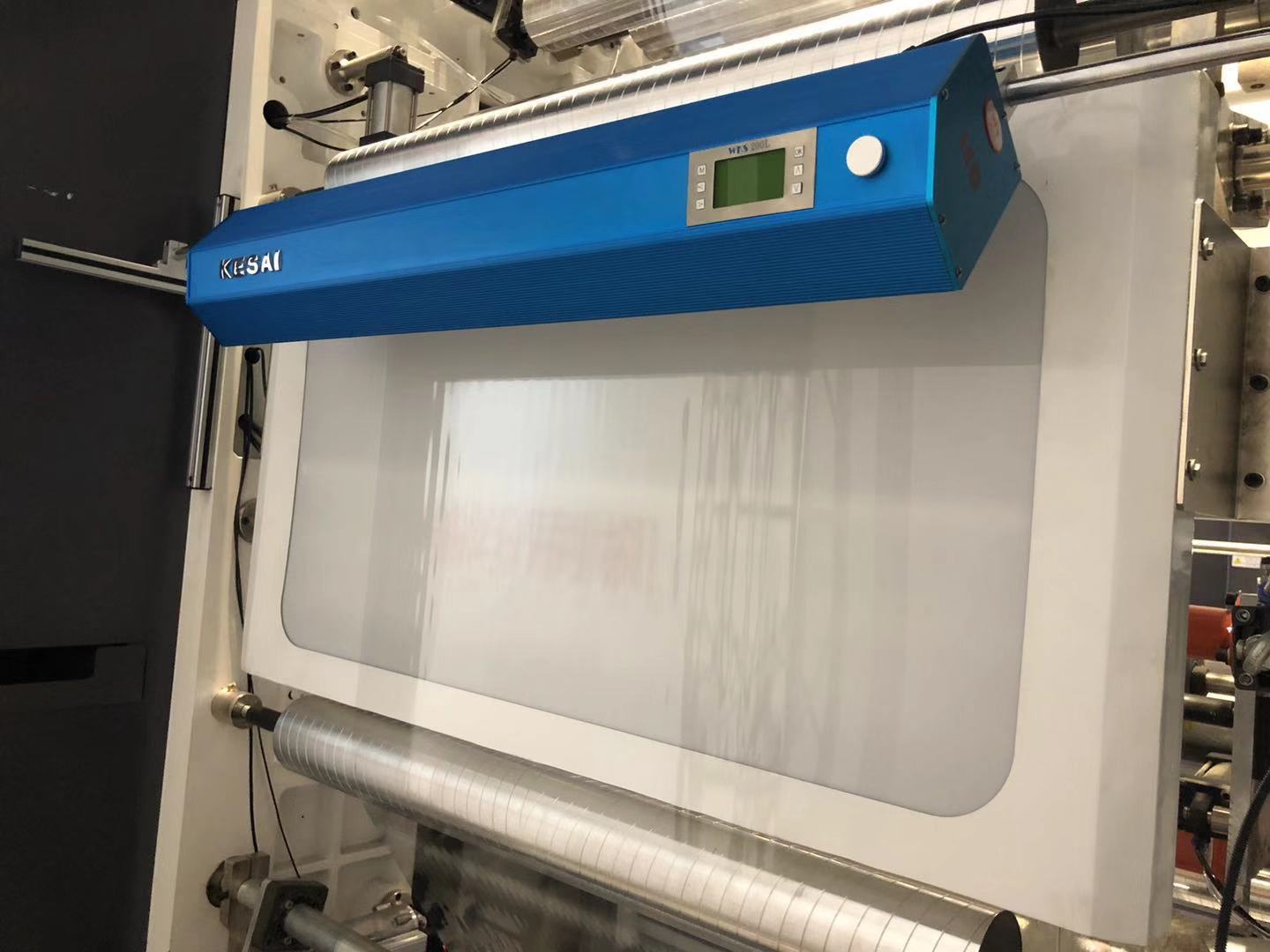

stroboscope

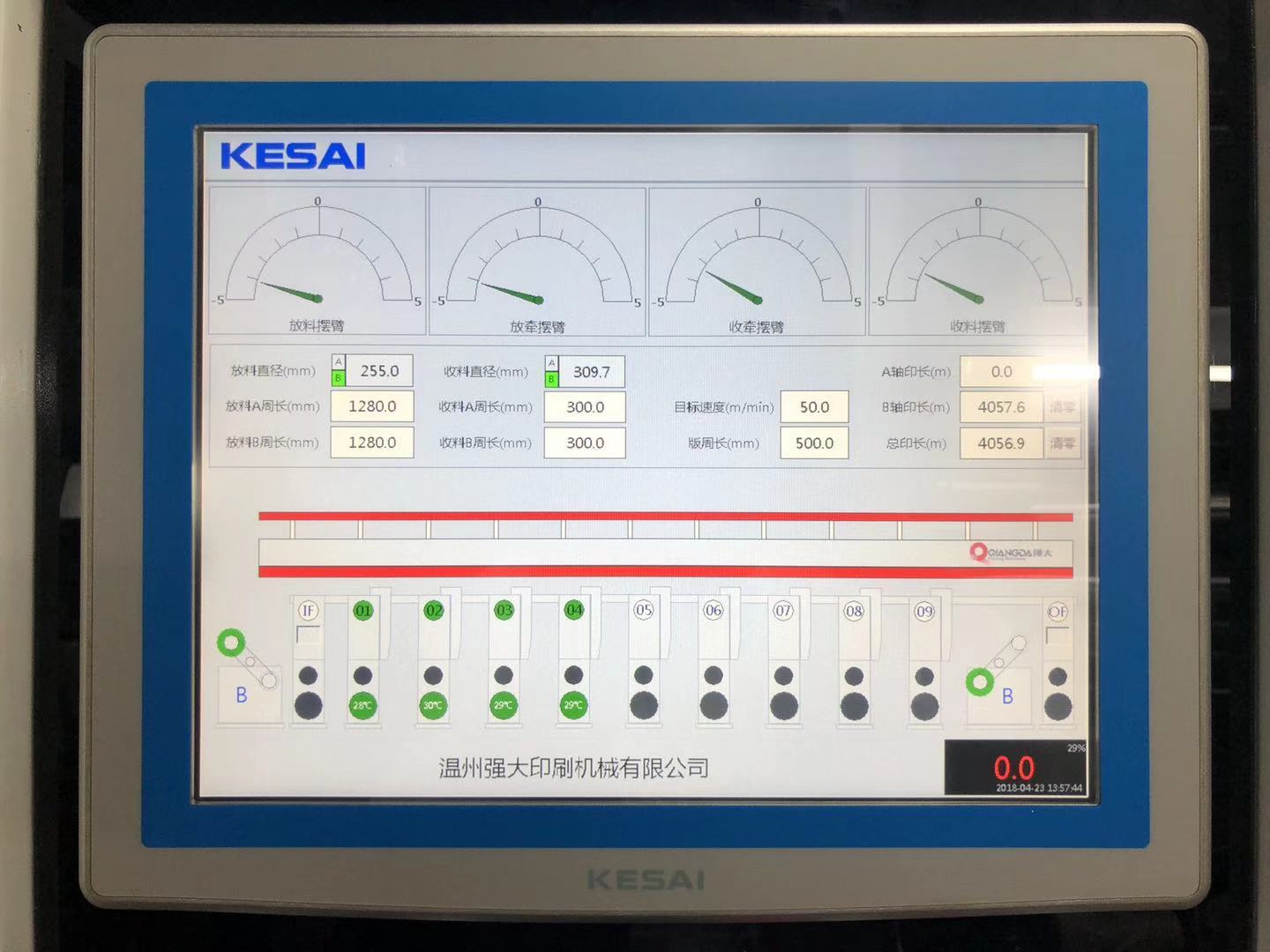

HMI

factory

-

Rotogravure printing machine 2 4 6 colors biodegradable plastic film

-

Wallpaper production equipment Non-woven wallpaper gravure printing line Cloth wallpaper embossing line

-

Cigarette paper engraving machine

-

Second-hand 8-color drop-roll gravure printing machine

-

Flexo ink proofer for gravure and flexo printing factories

-

Gravure printing machine 9 color cigarette case tipping paper printing machine

-

Rotogravure printing machine 8 colors price printing machine plastic rotogravure printing machine

-

mini rotogravure printing machine

-

Two-color gravure printing machine ASY-2800

-

Automatic color registration gravure circular arc rotogravure printing machine