Filter Centrifuge for plant trim and ethanol leaves

-

Supplier: Nanjing Kingreat Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Jimmy Gu -

Price: $5000.00 /set -

Min. Order: 1 set

| Type: | Centrifuge; | Applicable Industries: | Manufacturing Plant; |

| Power(W): | 1.1~11kw; | Supply Ability: | 100 Set/Sets per Month Oil Extraction Machine; |

| Grade: | GMP; | Certification: | ISO; |

| Packaging Detail: | Film wrapping+Wooden case fumigated for Oil Extraction Machine; | Place of Origin: | Jiangsu China; |

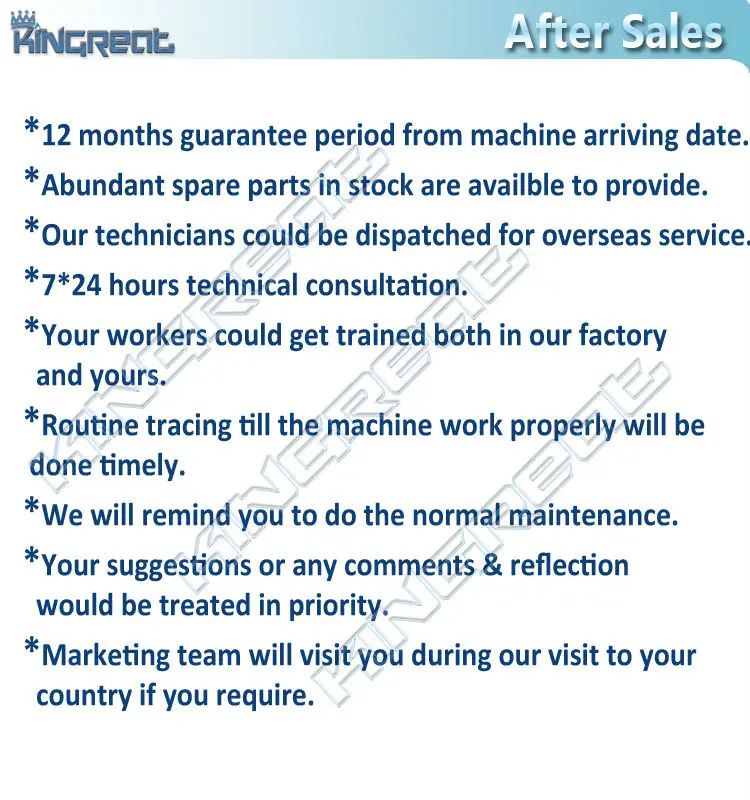

| Dimension(L*W*H): | Depends on the model; | After-sales Service Provided: | Field installation, commissioning and training; |

| Application: | Hemp Oil Extraction Machine; | Warranty: | 12 months; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | CIP system: | Optional; |

| Port: | Nanjing,Shanghai,Ningbo; | Operation: | Batch; |

| Surface inside and outside: | Polished; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Condition: | New; | Discharge type: | Top discharge, manual; |

| Product Type: | Industrial Centrifuge; | MOC: | SS304,316 as option; |

| Base: | Platform with vibration absorber; | Voltage: | 220V,380V,440V,480V...; |

| Brand Name: | Kingreat; | Speed control: | Inverter (optional); |

| Weight: | Depends on the model; |

The PPTD centrifuge is top discharging, hermetic closure type equipment. The material is fed into the drum through the feeding pipe on the hermetic closure casing; under the action of the centrifuge force field, the liquid-phase passes through the filter medium and the discharged out of the machine, while the solid-phase material is retained inside the drum and, after the machine is stopped, the material is discharged from the top. The centrifuge has such features as smooth running, easy & convenient operation as well as conducting feeding, washing and dehydrating under the state of hermetic closure, etc.

| Model | Length (mm) | Width (mm) | Height (mm) | Power (kw) | Weight (kg) | Capacity (kg/hr) |

| PPTD-25 | 980 | 650 | 870 | 1.5 | 250 | 25 |

| PPTD-50 | 1300 | 880 | 900 | 3 | 800 | 50 |

| PPTD-135 | 1800 | 1200 | 1140 | 5.5 | 1300 | 135 |

| PPTD-200 | 2050 | 1500 | 1220 | 7.5 | 2000 | 200 |

| PPTD-300 | 2350 | 1650 | 1370 | 11 | 2500 | 300 |

·304 and 316L Sanitary Stainless Steel Construction

·Low temperature rating: -40c

·Reinforced Sight Glass

·Bi-Directional Agitation

·Auto/Manual Controls

·Digital HMI Interface

·Variable Speed Control

·Easy Material Loading/ Unloading

·Heavy-Duty Spin Drying

·No foundation required

1. System loading: A pre-loaded closed filter bag is placed into the basket

2. Program Menu: The 'Spray Wash' or 'Agitation Wash' program is selected on the HMI where the RPM and cycle times are set to the operator’s specifications.

3. Fill: Alcohol is connected from source tank into the centrifuge.

4. The Wash cycle: The plant material undergoes an agitated wash with a set number of bi-directional agitations

5. System Draining: When the wash cycle is complete, the outlet valve is manually opened and the liquid drained. The alcohol wash is pumped to a properly rated storage reservoir for further processing.

6. Spin Dry Cycle: The 'Spin Dry' menu is selected on the HMI and the drying cycle is started. The wet plant solids are spun dry of the remaining alcohol mixture within.

7. System Unloading: Upon completion of the 'Dry cycle', centrifuge is unloaded by taking the filter bag out from the basket.

8. Repeat Process.

1. Ex proof motor

2. PTFE Seals

3. Touch screen panel with PLC program

4. Inverter control box

5. On spot ex button

6. Closed type filter bags

7. Tri clamp fittings for feed and drain port

-

PSB800 vertical centrifuge uses centrifugal force to clean waste oil, top feeding and unloading

-

Plastic Coconut Oil Pipe Separator Centrifuge Tube Stainless Steel Made in China

-

All stainless steel 450 filter vibrating screen/soy milk machine liquid vibration filter with cart

-

Liquid-solid separator DAF biogas dissolved air flotation for other water treatment equipment

-

Bread Brewer's Yeast Disc Centrifuge with Nozzle (Nozzle Centrifuge)

-

Hot aluminum ash separator to process 700 degrees Celsius aluminum ash

-

Innovative solid decanter centrifuge

-

Laboratory economical/low price disc centrifuge

-

Large Capacity High Quality Cannabis Extraction Centrifuge

-

2018 honey centrifuge extractor and bee centrifuge honey machine

Other Products

-

$2680.00 - $2850.00 / set

$2680.00 - $2850.00 / set -

$17600.00 / set

$17600.00 / set -

$17600.00 / set

$17600.00 / set -

$7500.00 / set

$7500.00 / set -

$8200.00 / set

$8200.00 / set -

$16000.00 / set

$16000.00 / set