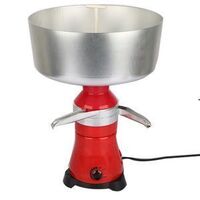

Laboratory economical/low price disc centrifuge

-

Supplier: Nanjing FiveMen Machine Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Sunny Cheng -

Price: $4000.00 / 1 - 1 units

$3000.00 / 2 - 2 units

$2000.00 / >=3 units -

Min. Order: 1 unit

| Voltage: | 220v/380v/415v | Main selling points: | high productivity |

| freed: | Manual unloading | type: | centrifuge |

| payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram | Name: | Laboratory economical/low price disc centrifuge |

| Supply capacity: | 50 units per month | Product Category: | Disc centrifuge |

| Warranty: | 1 year | Health status: | new |

| Origin: | Nanjing, China | Dimensions (L*W*H): | 496*330*610mm |

| strength: | 1.1KW | Motor Power: | 1.1KW |

| Packaging Details: | Standard wooden box and polyethylene film packaging | brand: | group of five |

| Showroom location: | not any | Separation factor: | 10000 |

| Local service location: | not any | Package preview: | |

| After warranty service: | Video technical support, online support, spare parts, on-site maintenance and repair services | port: | Shanghai |

| weight: | 80Kg | Noise level: | ≤85dB(A) |

| Certification: | International Organization for Standardization | Rated Capacity: | 10-300 |

| Drum speed: | 9500 rpm | Function: | Solid-liquid clarification or concentration |

| After-sales service provided: | On-site installation, commissioning and training, on-site maintenance and repair services, video technical support, online support | Applicable industries: | Food and beverage factory, food and beverage store, yeast separation/wine centrifuge |

Product Descriptionintroduce:

The disc separator can complete two operations: liquid-solid separation (separation of low-concentration slurry), called clarification operation; liquid-liquid (or liquid-liquid-solid) separation (emulsion separation), called separation operation. Due to its compact structure, small footprint and high production capacity, the disc separator is widely used in chemical, pharmaceutical, light industry, food, biological engineering, transportation and other fields.

Disc separators separate solids and one or two liquid phases from each other in one separator

Single continuous process using extremely high centrifugal forces. when dense solid

With this force, they are forced outward against the rotating bowl walls, while the smaller

The dense liquid phase forms concentric inner layers. The area where the two different liquids reside

The phase meeting is called the interface position. This can easily be changed to ensure

Separation takes place with maximum efficiency. Insert special plates ("plate stacks")

Provides additional surface settling area to help speed up the separation process

Dramatically. It is the special configuration, shape and design of these boards that make them

The disc centrifuge can continuously separate a variety of

Different solids from one or two liquids. The concentrated solid phase consists of

Depending on the centrifuge type, pellets can be removed continuously, intermittently or manually

and the amount of solids involved in a particular application.

application:

Widely used in chemical industry, pharmaceutical, petroleum, food, dairy industry, daily industry, national defense industry, etc.:

1. Food industry: used for the extraction and separation of animal protein, as well as the refining of animal fat in meat processing or the concentration and separation of fish oil in aquatic products, the clarification and degreasing of milk, the clarification of beer and malt, sparkling wine, fruit juice and drinks etc.

2. Chemical industry: mainly used to separate industrial chemicals, paints and coatings. It can also be used for clarification and purification of waste water in light industry, textile, chemical fiber and other industries, as well as larger density solid phase analogues. It is also used for the concentration and clarification of natural rubber, and the rubber latex is separated into concentrated latex and clear rubber. At the same time remove solid impurities in serum.

3. Pharmaceutical industry: mainly used for separation of biopharmaceuticals, pharmaceuticals, vaccines, mycelia, glucose, insulin, vitamins, antibiotics, pigments, proteins, spices, etc.

4. Oil industry: Vegetable oil, animal fat, fish oil, soap oil, biodiesel oil, and gutter oil can be used as raw materials, and can be obtained by transesterification through a new centrifugal separation process.

5. Other industries: Mainly used to remove water and mechanical impurities from the fuel and lubricating oil of ship main engines, diesel power stations and other equipment, as well as other types of mineral oils, so as to reduce the wear and tear of diesel engines or other machinery and prolong the service life. Mechanical service life. It is also suitable for the separation and clarification of waste oil and similar materials in other petrochemical industries, such as black oil, delayed coking oil, washing oil, recycled oil, etc.

Model: | SYDR302 |

Drum speed: | 9500 rpm |

separation factor | 10,000 |

Slagging method: | Manual unloading |

Noise sound pressure level: | ≤90dB(A) |

Motor Power: | 1.1kW, 380V/50Hz |

weight: | 900 kg |

aspect: | 496X330X610mm (length X width X height) |

detailed image

other products

our company

Over the years, our products have been successfully used in mineral oil, dairy products, fruit and vegetable juices, pigments, animal and vegetable oils, starch, biopharmaceuticals, fermentation broth, additives, food, oil extraction, fish oil feed, feed grading non-metallic minerals, petrochemicals, Sewage treatment and other industries. Customers are all over the country except Tibet, and the products have been successfully exported to Japan, North Korea, South Korea, Taiwan, Thailand, Malaysia, Vietnam, Myanmar, India, the United States, Africa and some Latin American countries.

It has passed the ISO9000 quality system certification of China Classification Society; the mineral oil separator used for inland river, offshore and ocean transportation has obtained the CCS approval certificate, and the products used for fishing boats have also passed the fishery inspection. Over the years, it has won many honors such as "Jiangsu High-quality Products", "Jiangsu Quality, Service, and Credit AAA Demonstration Unit", "Jiangsu Star Enterprise", and "AAA Brand". Quality Integrity Enterprise of Jiangsu Province", etc.

Our Services and Frequently Asked Questions

The warranty period of the whole machine is one year, excluding pipes and human factors, etc., and the after-sales service is 12 months from the date you receive the machine or 12 months after the installation is completed;

Machine life consulting service, 24-hour email technical support;

UPS, English software, user manual and installation and commissioning by our experienced technicians.

1. Can your machines meet our needs well?

We will advise you on your specific requirements and each machine is customized to meet the customer's needs.

2. Are you a factory or trading company?

We are a manufacturer and have been in this industry for more than ten years.

3. What is your payment method?

By wire transfer directly from our bank account, or by Alibaba's trade assurance service, or by Western Union, or cash.

4. How can we ensure the quality of the machine after we place an order?

Before shipping, we will send you the pictures and videos of the machine, or you can come to us for quality inspection by yourself, or by the third-party testing agency you contact for quality inspection.

5. I'm afraid you won't give us the machine after we paid the money.

Please note our above business license and certificate. If you don't trust us, you can use Alibaba's trade assurance service or L/C.

6. Why choose your company?

We have specialized in the manufacture of various packaging machinery for more than 10 years, and we can provide better after-sales service.

the feedback

-

PSB800 vertical centrifuge uses centrifugal force to clean waste oil, top feeding and unloading

-

Plastic Coconut Oil Pipe Separator Centrifuge Tube Stainless Steel Made in China

-

All stainless steel 450 filter vibrating screen/soy milk machine liquid vibration filter with cart

-

Liquid-solid separator DAF biogas dissolved air flotation for other water treatment equipment

-

Bread Brewer's Yeast Disc Centrifuge with Nozzle (Nozzle Centrifuge)

-

Hot aluminum ash separator to process 700 degrees Celsius aluminum ash

-

Innovative solid decanter centrifuge

-

Large Capacity High Quality Cannabis Extraction Centrifuge

-

2018 honey centrifuge extractor and bee centrifuge honey machine

-

Flottweg used Z34-4/053 decanter centrifuge (sold out)

Other Products

-

$2000.00 / unit

$2000.00 / unit -

$5500.00 / unit

$5500.00 / unit -

$160.00 / unit

$160.00 / unit -

$5600.00 / unit

$5600.00 / unit -

$25000.00 / unit

$25000.00 / unit -

$160.00 / unit

$160.00 / unit -

$9400.00 / unit

$9400.00 / unit