GQ High Speed Yeast Bacteria Centrifuge Separator Tubular Centrifuge

-

Supplier: Nanjing FiveMen Machine Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Sunny Cheng -

Price: $5600.00 /unit -

Min. Order: 1 unit

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union; | Power: | 2.2kw; |

| Machinery Test Report: | Provided; | Key Selling Points: | High Productivity; |

| Keyword: | yeast bacteria Centrifuge Separator; | Product Type: | industrial centrifuge machine; |

| Local Service Location: | Viet Nam,Indonesia,Pakistan,India,Russia,South Korea,Ukraine; | speed: | 16300 r/min; |

| Machine type: | GQ tubular; | Certification: | ISO; |

| Warranty: | 1 Year; | Max centrifugal force: | 15750 R.C.F; |

| Bearing: | SKF Bearing; | After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; |

| Dimension(L*W*H): | 760*450*1680; | Discharing way: | Manual discharge tubular; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Port: | all ports in China; |

| Capacity: | 200-3200L/H; | Name: | GQ High Speed Yeast Bacteria Centrifuge Separator Tubular Centrifuge; |

| Video outgoing-inspection: | Provided; | Place of Origin: | Jiangsu China; |

| Showroom Location: | None; | Package Preview: | ; |

| Packaging Detail: | Standard with wooden case and poly film wrapping for GQ solid liquid tubular bacteria body separator centrifuge; | Application: | all kinds of bacteria, juice and Beverage; |

| Material: | Stainless Steel 304/316; | Core Components: | Bearing,Motor; |

| Marketing Type: | Hot Product 2019; | Condition: | New; |

| Voltage: | 380V/220v/ 410v; | Warranty of core components: | 1 Year; |

| Brand Name: | Fivemen; | Supply Ability: | 30 Unit/Units per Month for tubular centrifuge; |

| Weight: | 400kg-1000kg; | Applicable Industries: | Food & Beverage Factory,bacteria; |

| Type: | tubular centrifuge; |

GQ solid liquid tubular bacteria body separator centrifuge

'

Tubular centrifuge has high performance of separate factor, high capacity, and account for small area and easy to handle, it has been widely used in pharmaceutical, health food, drinks, chemical industriesto separate the liquid-solid or liquid-liquid-solid materials. It is an ideal centrifuge take advantage of centrifugal methods, the minimum granules is 1 um, which is suitable for distill, condense and clarify the material has small gravity difference, small and few solid granules and high erosion products.

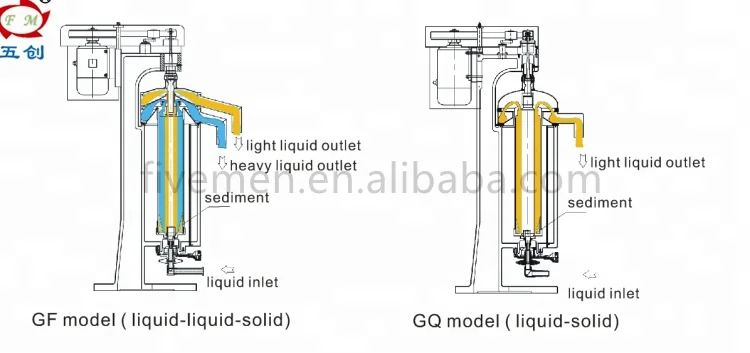

There is two types, for GQ tubular centrifuge which is used for the clarification.

Application:

GQ tubular centrifuge separators are for liquid solid clarification which mainly used for clarifying all kinds of liquid mixture which content very fine solid particles, such as coffee, tea, yeast, starch , bacteria and algae and etc.

The separator parts which contact with the materials are made of stainless steel. The machine body is iron casted which could be covered with stainless steel or coated with paintings according to the requirement of the customer.

Working principle of GQ:

It is a high-speed centrifuge with strong separating capacity. The liquid mixture is fed through the feeding pipe in the bottom of the separator, the bowl of the centrifuge is driven by the motor via spindle and rotates around its axis at a very high speed and forms a strong centrifugal force and this centrifugal force separates the liquid mixture into liquid and solid according to their different gravities. The liquid is drain out from respective liquid outlets on the top of the separator, in the meantime, the solids are deposited on the bowl's wall. When the accumulated solids full of the separator bowl, there will be no liquids drain out from the liquid outlets, the separator shall be stopped to remove the solid from the bowl manually.

|

|

GQ75 |

GQ105 |

GQ145 |

|

Drum speed |

20000R/min |

16300 r/min |

14000 r/min |

|

Max centrifugal force |

15600 |

15750 R.C.F |

16900 |

|

Drum inner diameter |

φ75 mm |

φ105 mm |

Φ145 mm |

|

Drum effective length |

450mm |

730 mm |

770 mm |

|

Solid volume in drum |

2.2L |

6 L |

8-12L |

|

Stuff inlet pressure |

<0.1Mpa |

<0.1Mpa |

<0.1Mpa |

|

Output (water flux) |

600L/H |

1500 L/H |

2500 L/H |

|

Motor power |

1.5kw |

3KW |

3 KW |

|

Specification |

760 x 450 x 1120 |

760×450×1680 mm |

890*580*1670 mm |

|

Weight |

200KG |

500kg |

700kg |

-

PSB800 vertical centrifuge uses centrifugal force to clean waste oil, top feeding and unloading

-

Plastic Coconut Oil Pipe Separator Centrifuge Tube Stainless Steel Made in China

-

All stainless steel 450 filter vibrating screen/soy milk machine liquid vibration filter with cart

-

Liquid-solid separator DAF biogas dissolved air flotation for other water treatment equipment

-

Bread Brewer's Yeast Disc Centrifuge with Nozzle (Nozzle Centrifuge)

-

Hot aluminum ash separator to process 700 degrees Celsius aluminum ash

-

Innovative solid decanter centrifuge

-

Laboratory economical/low price disc centrifuge

-

Large Capacity High Quality Cannabis Extraction Centrifuge

-

2018 honey centrifuge extractor and bee centrifuge honey machine

Other Products

-

$2000.00 - $4000.00 / unit

$2000.00 - $4000.00 / unit -

$2000.00 / unit

$2000.00 / unit -

$5500.00 / unit

$5500.00 / unit -

$160.00 / unit

$160.00 / unit -

$25000.00 / unit

$25000.00 / unit -

$160.00 / unit

$160.00 / unit -

$9400.00 / unit

$9400.00 / unit