Bread Brewer's Yeast Disc Centrifuge with Nozzle (Nozzle Centrifuge)

-

Supplier: Liaoning Fuyi Machinery Co., Ltd. -

Region: Liaoning, China -

Contact: Ms Molly Sun -

Price: $15000.00 /unit -

Min. Order: 1 unit

Product details

| payment terms: | L/C, T/T | weight: | Chapter 580 |

| type: | centrifuge | Main selling points: | high productivity |

| Core component warranty: | 1 year | brand: | Richpeace |

| Packaging Details: | Standard export wooden box | port: | Dalian |

| Mechanical test report: | if | Health status: | new |

| Showroom location: | not any | Marketing Type: | Hot Products of 2019 |

| Voltage: | 380V or customer order | Dimensions (L*W*H): | 1200*1500*2200 |

| Warranty: | 12 months | Product Category: | Disc centrifuge |

| Applicable industries: | Manufacturing plants, food and beverage factories, farms | strength: | 11~55kw |

| Origin: | China | Supply capacity: | 10 bacillus separators per month |

| Core components: | engine | Video outbound inspection: | if |

Product Description

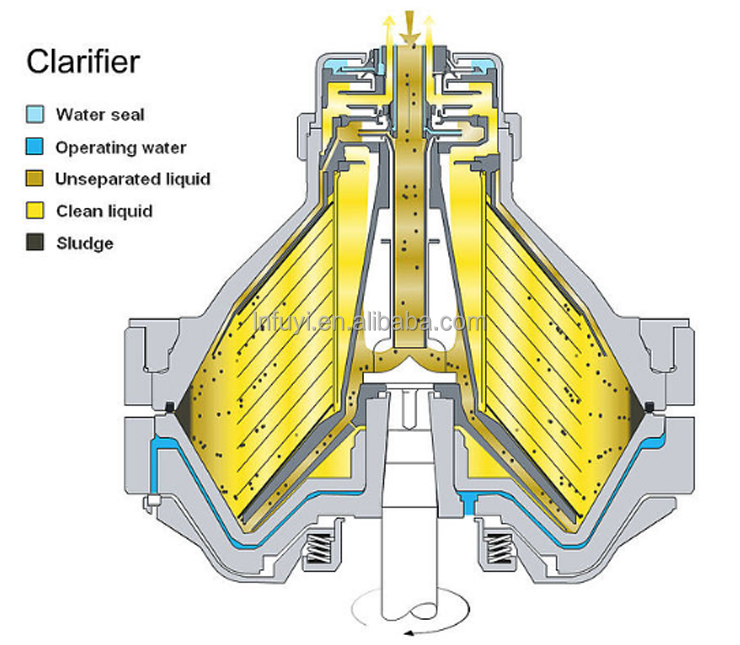

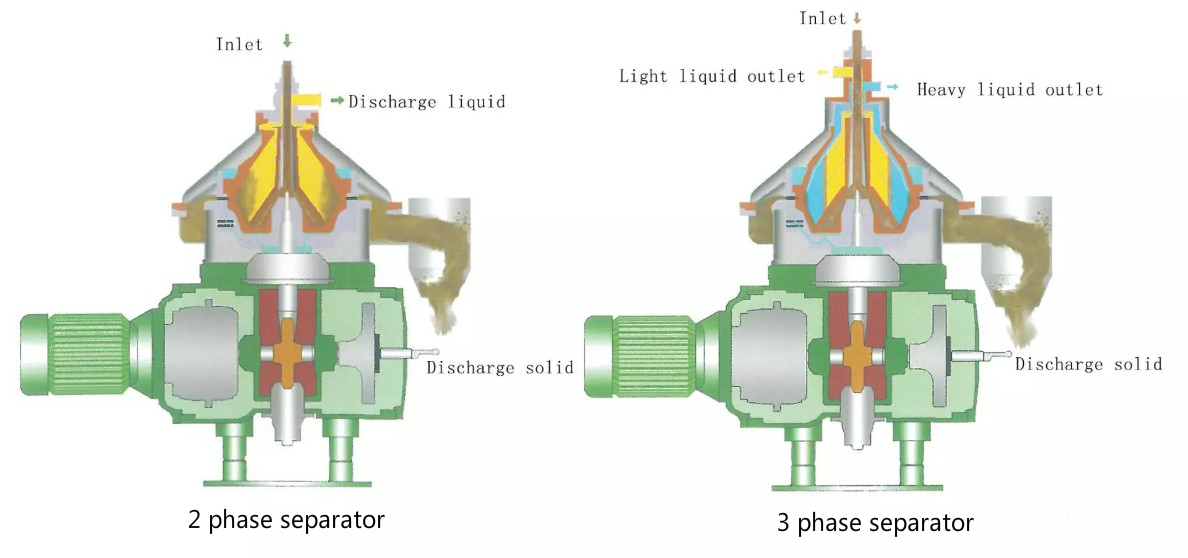

Application of beer centrifugeCentrifuge applications in craft beer include pre-filtration, yeast count control, and recovery of wort from hot curds. Centrifugation is an important step in the brewing process in which beer centrifuges remove solids such as yeast and hops from draft beer and transfer them to maturation vessels for final conditioning, preventing unwanted particles from entering the final productFeatures of beer centrifugeMany brewing equipment manufacturers have been able to design and manufacture high-quality, fully functional new beer centrifuges. Let's take a look at the features of this centrifuge: It has an inert gas closure system that minimizes the entry of oxygen into the clarified product, ensuring that the oxygen gain behind the centrifuge does not exceed 10ppb. The ability to monitor all functions and self-adjust to maintain operating settings ensures trouble-free and safe operation at all times. The self-cleaning design of the centrifuge does not need to be disassembled for cleaning, and it has a CIP online cleaning system. Through the circulation system, the beer stays cool enough.Advantages of beer centrifugeCentrifuges can significantly reduce processing time and increase yields compared to traditional filtration and sedimentation methods. Control the clarity of total suspended solids in beer prior to direct bottling. Keep inlet and outlet temperatures low to minimize flavor and texture loss, extending product shelf life. With variable frequency drives, increased service life and reduced costs, craft beer can return on investment in a short period of time.

feature:1. The machine starts friction start, about six to ten minutes. The machine runs smoothly, with low noise and vibration, and the installation path is very easy to operate. 2. The stainless steel cover adopts SUS304. 3. The base is made of cast steel with the same coating as the bottom of the ship. 4. Independent electric control cabinet, which can be controlled remotely. 5. Safety protection: speed detection, over-vibration protection, cover opening protection, motor

Technical Parameters

Model | DHC230 | DHC230 | DHC300 | DHC360 | DHC470 | ||||

Discharge time and interval | The discharge time is adjustable from 0.1-0.9 seconds, and the discharge time interval is adjustable from 1-240 minutes according to the raw materials. | 75 | 105 | 125 | 150 | ||||

Speed rpm | 7500-10000 | 7500 | 7300 | 7070 | 6600 | ||||

Water capacityL/H | 500 | 500-1500 | 500-2000 | 500-3000 | 500-5000 | ||||

Motor power KW | 1.5 | 4 | 4 | 7.5 | 15/18 | ||||

weight kg | 180 | 450 | Chapter 580 | 1280 | 1720 | ||||

Customer factory

VIEW MORE

You may like

-

PSB800 vertical centrifuge uses centrifugal force to clean waste oil, top feeding and unloading

-

Plastic Coconut Oil Pipe Separator Centrifuge Tube Stainless Steel Made in China

-

All stainless steel 450 filter vibrating screen/soy milk machine liquid vibration filter with cart

-

Liquid-solid separator DAF biogas dissolved air flotation for other water treatment equipment

-

Hot aluminum ash separator to process 700 degrees Celsius aluminum ash

-

Innovative solid decanter centrifuge

-

Laboratory economical/low price disc centrifuge

-

Large Capacity High Quality Cannabis Extraction Centrifuge

-

2018 honey centrifuge extractor and bee centrifuge honey machine

-

Flottweg used Z34-4/053 decanter centrifuge (sold out)

Other Products

-

$14500.00 / set

$14500.00 / set -

$50000.00 / set

$50000.00 / set -

$38500.00 / set

$38500.00 / set -

$880.00 / piece

$880.00 / piece

Related Search

disc centrifuge

disc centrifug separator suppliers

dhc400 disc centrifuge

centrifuge with freezer suppliers

centrifugal disc finishing machine

disc stack centrifuge

rear axles with disc brake

brake disc with hub suppliers

abrasive paper discs with velcro suppliers

conical bottom centrifuge tube with graduated