CNC lathe controller NEW990TDCa 4 axis Turning machine controller

-

Supplier: Chengdu Newker CNC-Technology Co., Ltd. -

Region: Sichuan, China -

Contact: Mr James Liao -

Price: $300.00 /piece -

Min. Order: 1 piece

| Delivery Detail: | Normally ready goods and stock within 1-3days; | Supply Ability: | 10000 Set/Sets per Month lathe controller; |

| Function: | PLC+ATC; | After-sales Service Provided: | No overseas service provided; |

| Axis: | 4 axis cnc controller board; | Model Number: | NEW990TDCa-4; |

| Max. Swing Diameter: | 400mm; | Weight: | 10kg; |

| Power(W): | 80w; | Type: | Horizontal; |

| Automatic Grade: | Automatic; | Certification: | CE; |

| Dimension for hole: | 380*226; | Brand Name: | NEWKer-CNC lathe controller; |

| Dimension(L*W*H): | 400*245*125; | Speed: | 30m/min; |

| Port: | Any ports of China; | Voltage: | 220V; |

| Condition: | New; | CPU: | ARM(32bits)+DSP+FPGA; |

| Place of Origin: | Sichuan China (Mainland); | Packaging Detail: | 1.Industrial packing(lathe controller): plastic bag +styrofoam+ carton +wooden pallets 2.Commercial packing: plastic bag+styrofoam+ carton 3.As the clients' requirement; |

| Port: | 24input 24output; | Payment Terms: | L/C,T/T,Western Union,Paypal; |

| User Store Room: | 128Mb; | CNC or Not: | CNC; |

| Interface: | USB+RS232 Communction Port; | Program: | User Macro Program; |

| Display: | 8 Inch Real Color LCD; |

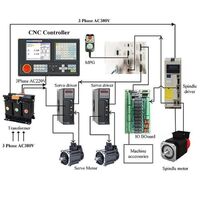

1.Product Name:CNC lathe controller NEW990TDCa-4

2. Axis: 4 axis cnc controller board

3. For machine tools:cnc lathe、special machine tools

Product features

★Adapt bus modbus technology, ARM + DSP + FPGA technology

★USB and RS232 port, DNC function of USB (NEW)

★Network remote technology and could diagnose the system online (NEW)

★User's storage is 128M and could be infinite number of program (NEW)

★Abosolute type of motor (17bits multi circle) controlling technology (NEW)

★The most moving rapid speed is 300m/min, processing speed reaches 0.01 ~ 30m/min (NEW)

★The cycle of interpolation is 2ms, controlling accuracy is 0.1um (NEW)

★All closed-loop with grating ruler control and the accuracy is <2um (NEW)

★Preread the short line program to satisfy with high speed engraving and cutting (NEW)

★Intelligent Man-Machine dialog interface (NEW)

Our Seller

Name:JinHua Chen

Tel:13981709850

QQ:706983380

E-mail:706983380 @qq.com

Our Techinical Service

Name:GuangCan Liao

Tel:13550063039

QQ:357022449

E-mail:357022449 @qq.com

Our Customer Service

Name:Xin Liao

Tel:13548198210

QQ:461536982

E-mail:461536982 @qq.com

Factory

Warehouse

Our Warehouse

Test Room

24 hours work in different tempreture and humidity

Reception

Our Reception

1.Industrial packing(lathe controller): plastic bag +styrofoam+ carton +wooden pallets

2.Commercial packing: plastic bag+styrofoam+ carton

3.As the clients' requirement

Delivery Detail: Normally ready goods and stock within 1-3days

Our product after strict many test and examine

Our purpose:

Make the most practical ideal CNC system

Casting the high-quality goods to service the world

Our customer

Our customer is delivering the machines with our compelete set of system (Our system, our driver and our motor).

Our customer

Processing customer is using our set of system to reduce their manual work.

Our customer

Our customer is on an exhibition with our set of system and our mechanical hand to realize non-manual control.

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: 100% in advance.

-

Car lathe rim aluminum alloy rim diamond cutting machine rim refurbishment CNC wheel straightening repair machine

-

Diamond Cutting Polishing Machine Alloy Wheel Restoration CNC Lathe

-

CE Approved Wheel Restoration Diamond Cut Horizontal Lathe CNC Machine For 18' 19' 20' 22' 24' Forged Wheels

-

Low Cost Horizontal Precision Metal Lathe Machine Engine Lathe

-

CNC Slant Bed Lathes

-

Horizontal CNC lathe, Milling Machine

-

T2S500 German Technology High Quality Low Price Inclined Bed CNC Lathe Machine Tool CNC Machinery Wholesale Supplier Manufacturer

-

Mini CNC Lathe CK0632A Hot Selling Mini CNC Lathe Micro CNC Lathe

-

China CK210 Mini CNC Lathe

-

DMTC DT30/DT40/DT50 Inclined Bed CNC Lathe China CNC Lathe Horizontal Inclined Bed CNC Lathe Cheap Price

Other Products

-

$300.00 - $380.00 / piece

$300.00 - $380.00 / piece -

$5000.00 / piece

$5000.00 / piece -

$630.00 / piece

$630.00 / piece -

$360.00 / piece

$360.00 / piece -

$400.00 / piece

$400.00 / piece -

$400.00 / piece

$400.00 / piece -

$10000.00 / piece

$10000.00 / piece -

$400.00 / piece

$400.00 / piece -

$500.00 / piece

$500.00 / piece