Die iron wire drawing machine for nail making machine

-

Supplier: Xuchang Hongshuo Machinery Co., Ltd. -

Region: Henan, China -

Price: $6000.00 /set -

Min. Order: 1 set

Product details

| Function: | smaller diameter | Inlet diameter: | 6.5-2.0mm |

| quality: | High standard wire drawing machine | Supply capacity: | 200 sets of die steel wire drawing machine for nail making machine per month |

| Warranty: | 2 years after installation | Certification: | ISO9001:2008 |

| port: | Qingdao Port | Applicable industries: | Building materials stores, manufacturing plants, construction projects |

| Core components: | Gearboxes, Pressure Vessels, Pumps, Gears, Bearings, Engines, Motors, PLCs | type: | wire machine |

| place of origin; place of origin: | Henan, China | Local service location: | not any |

| Health status: | new | application: | Drawing process |

| Video external inspection: | if | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Motor Power: | 15-50kW | Showroom location: | not any |

| After-sale service: | if | After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services |

| Voltage: | 380/415/440/220V | Packaging Details: | Wooden box or sea worth die iron steel wire drawing mechanism nail machine |

| Main selling point: | competitive price | usage: | brushed metal |

| color: | Require | Core Components Warranty: | 2 years |

| brand: | Hongshuo | Outlet diameter: | 0.8-5.5mm |

| year: | 2020 | Mechanical test report: | if |

| Marketing Type: | New Products 2020 | Applicable materials: | Medium and high carbon steel wire |

| strength: | 15-50kW | product name: | Die iron wire drawing machine for nail making machine |

Product Description

Die iron wire drawing machine for nail making machine

If the wire diameter is thick before entering the nail making machine, the machine can reduce the wire diameter, and the user can get the wire diameter they need. 2 combinations, 3 combinations, 4 combinations or more combinations can be matched according to the daily production capacity.

model. | LS3-560 | |||

Maxim's incoming wire diameter | 6.5mm | |||

Minimum outlet diameter | 2.0mm | |||

total motor power | 15kw*3+2.2kw | |||

drawing speed | 150 m/min | |||

TIPS: If you buy the wire coil of suitable diameter directly from the market, no wire drawing machine and auxiliary equipment (shiatsu machine and butt welding machine) are required. | ||||

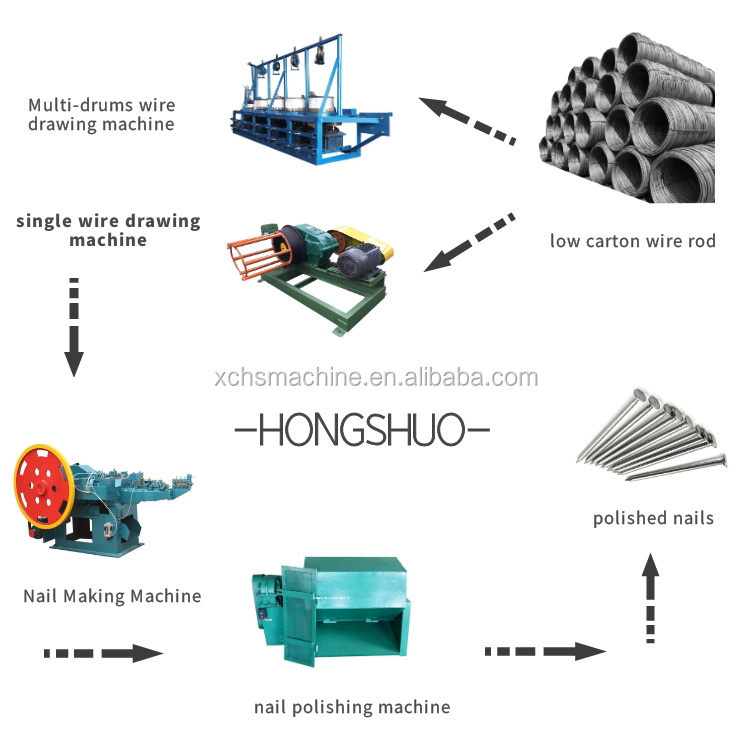

Process flow

detailed image

Auxiliary equipment

1. Pointing and rolling machine

Solder the two coils together for continuous operation.

Function: sharpen the thread end, so that the coil can easily enter the wire drawing machine.

model. | scroll to range | Motor Power | total measurement | weight |

Pointing Roller | ≤8mm | 2.2KW | 1.2*0.6*1.0m | 80kg |

2. Butt welding machine

Solder the two coils together for continuous operation.

Function: Weld two wire coils together to maintain the continuity of the drawing process.

model. | Butt welding range | Voltage | weight |

Butt welding machine | φ3—φ8mm | 380V 50HZ | 50kg |

manufactures

manufactures

Wire diameter 6.5-2.0mm

VIEW MORE

You may like

-

Annealed wire high-speed linear drawing machine, galvanized wire winding machine

-

Monoblock drawing machine for steel bar drawing

-

wet drawing machine

-

Automatic Sheet Metal Polishing Deburring Machine Wide Band Sander For Cutting And Stamping Parts

-

Fire extinguisher barrel deep drawing hydraulic press

-

Cold Rolling Equipment Manufacture 3 Ribbed Steel Bar Machine

-

Small wire drawing machine for making copper wire

-

3 drum wire drawing machine / wire drawing machine

-

Low carbon steel straight wire drawing machine for wire binding

-

0.7mm-0.13mm kitchen Baibao wire drawing machine, stainless steel wire drawing machine

Other Products

-

$5000.00 / set

$5000.00 / set -

$5000.00 / set

$5000.00 / set -

$5000.00 / set

$5000.00 / set -

$2000.00 / set

$2000.00 / set -

$2000.00 / set

$2000.00 / set

Related Search

iron wire drawing machine

wire drawing machine for copper

copper wire drawing machine

aluminium wire drawing machine

wire drawing machine

horizont type wire draw machin suppliers

wuxi supply wire drawing machine

use copper wire drawing machine price

heavy copper wire drawing machine

nickel wire drawing machine