GNZ-type Mineral Gold Ore Thickener Tank Peripheral Transmission Slurry Gravity Thickener

-

Supplier: Nuclear Industry Yantai Toncin Group Co., Ltd. -

Region: Shandong, China -

Price: $15000.00 /set -

Min. Order: 1 set

| Application: | Solid-liquid separation,Solid-liquid separation; | Machinery Test Report: | Provided; |

| Port: | QINGDAO; | Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; |

| Place of Origin: | Shandong China; | Condition: | New; |

| Life: | More than 35 years; | After-sales Service Provided: | Overseas service center available; |

| Capacity: | customized; | Payment Terms: | L/C,T/T; |

| Warranty: | 2 years; | Packaging Detail: | Export package; |

| Local Service Location: | Pakistan,Russia,Chile,Kazakhstan,Kyrgyzstan,Uzbekistan; | Payment: | L/C or T/T; |

| Dimension(L*W*H): | Customized; | Brand Name: | Toncin; |

| Packing: | Seaworthy package; | Production Capacity: | Customized; |

| Supply Ability: | 200 Set/Sets per Year; | Warranty of core components: | 3 years; |

| Certification: | CE, ISO 9001, IS0 14001,CE, ISO 9001, IS0 14001; | Motor Type: | AC Motor; |

| Marketing Type: | New Product 2020; | Material: | Customized; |

| Video outgoing-inspection: | Provided; | Applicable Industries: | Energy & Mining; |

| Control: | Automatic; | Showroom Location: | None; |

| Product name: | GNZ-type Mineral gold ore thickener tank price; | Type: | Mining Thickener; |

GNZ-type Mineral gold ore thickener tank price

New type high rate thickener introduces the function of flocculant assisted dehydration, at the same time, according to the requirements of the application in different industries, by optimizing the structure of the equipment and flocculant assisted dehydration, newly developed new type thickener has the advantages of concentrating efficiency greatly accelerated, Throughput enlarged and high underflow concentration; It has been widely used in the dewatering of various metal and non-metallic ores, and the slurry solid-liquid separation in Introduction.

The vertical axis rotates driven by motor, and pulp by feeding device flows into the tank center feed mixing barrel.Solid material in the bottom of the tank by the scraper moves out of center; clarified overflow through the tranquil flow device flows out from the ring external overflow weir.The vertical axis rotates driven by motor, and pulp by feeding device flows into the tank center feed mixing barrel.Solid material in the bottom of the tank by the scraper moves out of center; clarified overflow through the tranquil flow device flows out from the ring external overflow weir.The vertical axis rotates driven by motor, and pulp by feeding device flows into the tank center feed mixing barrel.Solid material in the bottom of the tank by the scraper moves out of center; clarified overflow through the tranquil flow device flows out from the ring external overflow weir.The vertical axis rotates driven by motor, and pulp by feeding device flows into the tank center feed mixing barrel.Solid material in the bottom of the tank by the scraper moves out of center; clarified overflow through the tranquil flow device flows out from the ring external overflow weir.The vertical axis rotates driven by motor, and pulp by feeding device flows into the tank center feed mixing barrel.Solid material in the bottom of the tank by the scraper moves out of center; clarified overflow through the tranquil flow device flows out from the ring external overflow weir.

|

Model |

Concentration tank |

Sediment area |

The lifting height of rake(mm) |

Rake rotating speed(r/min) |

Motor Power |

|

|

Diameter(m) |

Depth(m) |

|||||

|

GNZ-3 |

3 |

2.5 |

10 |

300 |

0.1-0.2 |

3+1.1 |

|

GNZ-6 |

6 |

3.0 |

28 |

300 |

0.1-0.2 |

4+1.5 |

|

GNZ-9 |

9 |

3.2 |

63 |

300 |

0.1-0.2 |

4+1.5 |

|

GNZ-12 |

12 |

3.5 |

110 |

300 |

0.1-0.2 |

4+1.5 |

|

GNZ-18 |

18 |

4.4 |

254 |

600 |

0.1-0.2 |

7.5+2.2 |

|

GNZ-20 |

20 |

4.4 |

310 |

600 |

0.1-0.2 |

7.5+2.2 |

|

GNZ-24 |

24 |

5.2 |

452 |

600 |

0.05-0.2 |

7.5+2.2 |

|

GNZ-30 |

30 |

5.2 |

707 |

600 |

0.05-0.2 |

11+3 |

|

GNZ-38 |

38 |

5.5 |

1134 |

600 |

0.05-0.2 |

15+4 |

|

GNZ-45 |

45 |

5.5 |

1590 |

600 |

0.05-0.1 |

37+4 |

|

GNZ-53 |

53 |

6.0 |

2206 |

600 |

0.05-0.1 |

37+4 |

|

GNZ-60 |

60 |

6.0 |

2826 |

600 |

0.03-0.1 |

45+5.5 |

|

GNZ-70 |

70 |

6.8 |

3846 |

600 |

0.02-0.05 |

45+5.5 |

|

GNZ-85 |

85 |

7.8 |

5671 |

600 |

0.02-0.05 |

45+5.5 |

Note:

1. The above parameters are only for reference. As the settlement performance of materials is relatively large, the specific parameters are subject to the design drawings provided by our company.

2. Our company can design thickener with different models according to the requirements of users.

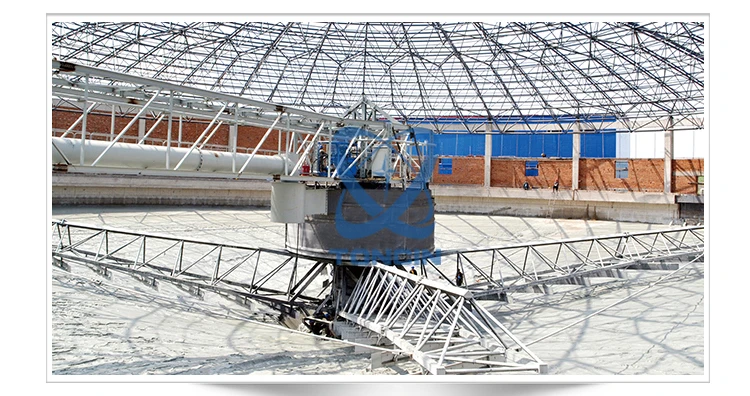

This thickener consists of round thickener and harrow scrapping machine, the solid particles suspend in thickener settling by gravity, the pulp in the upper turn into clean water, so that the separation can be realized. Slime that sediment in the bottom of the thickener is discharged by the harrow scrapping continuously, and clean overflow from the upside.

1. High efficiency of concentration and scraping , which is three to five times than common thickener.

2.Excellent feed system——high-rate feed well:

a. The feed well makes the feed degas and have the energy dissipation, and it has tangential feeding.

b.Add the flocculant reasonably, and improve the efficiency .

c.It is equipped with distribution plate, which can take advantage of the effective area of the tank reasonably.

3. Driven lifting system with overweight design and large torque design can ensure the normal operation of the device. The thickener can not shut down in the extreme conditions, improving the efficiency of the device.

4.It adopts spiral design of rake teeth logarithm, and we can design rake teeth density according to material performance, which can improve the efficiency of scraping.

5.It has advanced thickener control system , automatically lifting rake, flocculant feeding, and automatically controlled underflow discharging pump

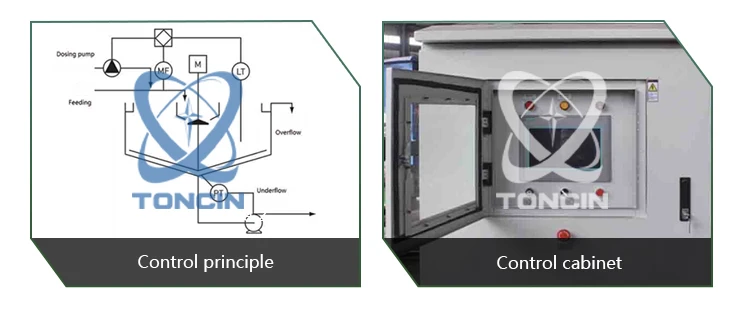

1.Design of main driving and rake lifting gear

1)Driving framework and chassis are made according to heavy type transmission device,

running is stable and reliable.

2)full automatic rake lifting.

3)Star transmission,the max running torque is 5000,000Nm.The designed torque of driving

transmission Is designed according to following standards.

a.Running torque value: 33% of the designed torque.

b.High torque alarm: 50% of the designed torque.

c.Rake rising; 60% of the designed torque.

d.Rake decreasing: 40% of the designed torque.

e.The designed torque value of mechanical device: 150% of the designed torque.

2 Control system

Site control and remote control are combined,DCS control points are supplied.

1,PLC control,overloading protection.

2,Material discharging terminal is set up with mud layer pressure sensor to control rotation

and mud discharging by pump.

Nuclear Industry Yantai Toncin Group Co.,Ltd. completed the restructuring and reorganization in June 2016, integrated 13 enterprises of filter industry, advanced manufacturing industry and new materials industry, set up the group company, formed the industrial pattern of common development of filtration separation machinery, new material industry and high-end equipment industry. Toncin group currently own 5 state-level high-tech enterprises, 3 provincial-level enterprise technology centers, 1 provincial-level industrial design center, maintain 177 valid patents, including 38 invention patents, presided and participated in the formulation of more than 10 national standards and industry standards of the Horizontal Belt Type Vacuum Filter, Vertical Automatic Diaphragm Filter Press, Joint Resistance to Static Cutting Performance Test Methods of Rubber or Plastic Coated Fabrics and so on. The company has received the "Shandong Energy-saving Environmental Protection Demonstration Enterprise", "Shandong Intellectual Property Advantage Enterprise", " Observes Contracts and Keep Promises Enterprise", "China Patent Shandong Star Enterprise", " Shandong Management Innovation Excellent Enterprise ", "Advanced Enterprise of Excellent Performance " and other honorary successively.

FAQ

1.Q:Are you a manufacturer or trading company?

A: We are a manufacturer, we have rich experience in solid liquid industry for more than 20 years.We are the Horizontal belt vacuum filter and TC ceramic disc vacuum filter,HVPF tower press filter leader of China.

2.Q:Do you have minimum order quantity request?

A: for spare parts we have no MOQ,but for whole set equipment of course 1 set is the minimum.

3.Q:Do you have certificates?

A: Yes, we have CE, ISO,SGS.etc. certificates.

4.Q:Can you meet my special requirements for my products?

A: Yes, we have rich experience and we have a professional design team. We can provide different drawings according to your requirements.

5.Q:How to pay?

A:T/T is acceptable.

6.Q:What is the delivery time?

A: It depends on order quantities. Generally speaking, the delivery time will be within 2 months.

7.Q:How to pack the products?

A: We use standard export package. If you have special package requirements, we will pack as you required, but the fees will be paid by customers.

8.Q:How to install after the equipment arriving destination?

A: We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you.

9.Q:How long is the validity?

A:The validity is 12 months after installation.

contact us

-

Low cost mud water sludge thickener liquid thickener

-

Hua Center Transmission Concentrate Tailings Thickener Dehydration

-

Ex-factory price copper-iron-lithium ore sedimentation tank sludge thickener

-

Fully automatic mine tailings concentrate treatment mud sewage sludge dehydration high-efficiency thickener price

-

Sludge Collector Circular Settling Thickener Tank Sludge Scraper Peripheral Drive Sludge Classifier Thickener Price For Sale

-

Gold ore cyanide leaching plant gold ore concentrator

-

Factory price sedimentation tank NZS-3 slime thickener for sale

-

Tailings gold beneficiation high-efficiency thickener

-

mine iron ore dewatering thickener/slurry sludge thickener tank sedimentation tank

-

Low Price Sludge Thickening Tank Supplier

Other Products

-

$42000.00 / set

$42000.00 / set -

$15000.00 / set

$15000.00 / set -

$2000.00 / set

$2000.00 / set -

$15000.00 / set

$15000.00 / set -

$10000.00 / set

$10000.00 / set -

$50000.00 / set

$50000.00 / set -

$100.00 / square meter

$100.00 / square meter -

$100.00 / square meter

$100.00 / square meter -

$14000.00 / set

$14000.00 / set -

$1000.00 / set

$1000.00 / set