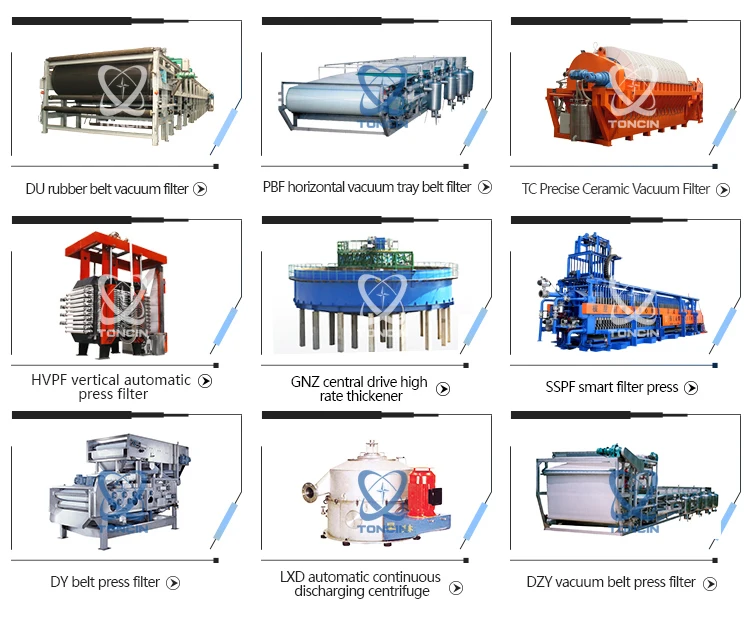

Large processing capacity sspf series automatic clay filter press

-

Supplier: Nuclear Industry Yantai Toncin Group Co., Ltd. -

Region: Shandong, China -

Price: $10000.00 /set -

Min. Order: 1 set

| Local Service Location: | Egypt,Turkey,Viet Nam,Philippines,Peru,Saudi Arabia,Indonesia,Pakistan,Russia,Spain,Thailand,Australia,Chile,Kazakhstan; | Marketing Type: | Ordinary Product; |

| After-sales Service Provided: | Engineers available to service machinery overseas,Field installation, commissioning and training; | Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; |

| Packaging Detail: | Export package; | Supply Ability: | 200 Set/Sets per Year; |

| Video outgoing-inspection: | Provided; | Applicable Industries: | Energy & Mining; |

| Weight: | According to filter size; | Capacity: | Customized; |

| Showroom Location: | None; | Power: | According to filter size; |

| Certification: | CE&ISO9001; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Payment Terms: | L/C,T/T; | Port: | QINGDAO; |

| Machinery Test Report: | Provided; | Life: | more than 34 years; |

| Dimension(L*W*H): | According to filter size; | Package Preview: | ; |

| Packing: | Seaworthy package; | Place of Origin: | Shandong China; |

| Automatic Grade: | Automatic; | Warranty of core components: | 3 years; |

| Warranty: | 1 Year; | Voltage: | According to filter size; |

| Control: | Automatic; | Material: | Customized; |

| Brand Name: | TONCIN; | Condition: | New; |

| Application: | Solid-liquid separation; |

Sspf series vacuum sludge dehydrating press filter in mining

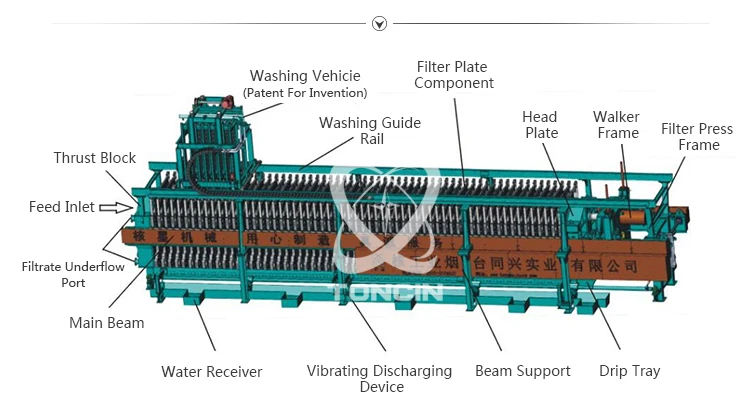

SSPF Smart Filter Press is a fast opening and closing plate filter press, mainly composed of the electrical control system, hydraulic control system and the host.When the equipment is operating, the hydraulic cylinder is driven by the mechanical transmission device and dragged and moved to reach the design ated position . After the hydraulic cylinder is locked by the locking device, the hydraulic cylinder is extended and all the filter plates are pressed together against each other so that the filter plates form a closed filter chamber. the slurry is pumped to each filter chamber through feeding holes by feeding pump, the solid liquid separation is achieved by the difference of the feeding pump's feeding pressure on the two sides of the filter medium, the material was withheld in the filter chamber, filtrate was guided out of plates' water-guide hole. After a period of time, the filtrate does not flow out and the filtration process is completed. According to the technical requirements, decide whether to do the high pressure diaphragm press, wash and air dry. After that, the lock device is unlocked, the hydraulic cylinder is withdrawn, then the hydraulic cylinder is driven by the mechanical transmission device and the filter plates are pulled apart. Finally, discharge the filter cake, clean filter cloth, then enter the next filter cycle.

|

Model |

filter Plates (layer) |

filter chambers volume (m³) |

Dimension (L*W*H )m |

Hydraulic Power (kw) |

plate size(mm) |

|

SSPF40 |

13 |

0.7 |

6.8*3.9*6.1 |

18.5 |

1500*1500 |

|

SSPF60 |

19 |

1.1 |

8.0*3.9*6,1 |

||

|

SSPF80 |

25 |

1.5 |

9.2*3.9*6.1 |

30 |

|

|

SSPF100 |

31 |

1.8 |

10.4*3.9*6.1 |

||

|

SSPF120 |

37 |

2.2 |

11.5*3.9*6.1 |

||

|

SSPF140 |

43 |

2.6 |

12.7*3.9*6.1 |

||

|

SSPF160 |

49 |

2.9 |

13.9*3.9*6.1 |

||

|

SSPF180| |

55 |

3.3 |

15.0*3.9*6.1 |

||

|

SSPF200 |

61 |

3.7 |

16.2*3.9*6.1 |

||

|

SSPF220 |

67 |

4 |

17.4*3.9*6.1 |

||

|

SSPF240 |

73 |

4.4 |

18.5*3.9*6.1 |

The equipment, using the pressure of pump, as well as the air pressure or water pressure, forms the pressure difference on both sides of the filter, so as to achieve high efficiency solid liquid separation. The technology of filter plate with quick opening and closing, hanging filter cloth, shock discharge, high pressure cleaning cloth and so on.It is a new type of horizontal pressure filter.

1.It is easier to drop the cake from the filter cloth by beating and unloading cake device.

2.The high pressure automatic walking filter cloth clean several numbers of cloth, and improve

the washing efficiency and filtration efficiency.

3.Quickly opening and closing, a short stroke compact, save auxiliary time.

4.Filter diaphragm pressure can reach to 1.6MPA, filter cake moisture is low.

5.Cloth can be directly disassembled from the top, easy to replace the filter cloth.

6.Intelligent control, equipment operation is safe and reliable.

Hydraulic jacking device can realize the mechanical working which make the filter plate group quickly opened and closed, hydraulic cylinder short stroke compressed, greatly reduce the hydraulic pressure.After automatic high pressure diaphragm press cake, cake moisture can be lower .Filter cake vibrating device makes the cake more easy detached from filter cloth.Automatic overturning discharge device ensures the filter cake and filtrate without any interference.High pressure automatic cloth cleaning device ensure the filter cloth regeneration high automatic safe and reliable, filter cloth replacement is convenient, high work efficiency.

It can be used to separate solid and liquid in the filed of metallurgy, mine, chemical industry, paper making, food, pharmacy and environmental protection.

Export package:We use standard export package or as you required.

Shipping:We will send our products within 2 months.

Transport way :By sea or by air.

Nuclear Industry Yantai Toncin Group Co.,Ltd. completed the restructuring and reorganization in June 2016, integrated 13 enterprises of filter industry, advanced manufacturing industry and new materials industry, set up the group company, formed the industrial pattern of common development of filtration separation machinery, new material industry and high-end equipment industry. Toncin group's enterprises mainly include Yantai Hejing Ceramic New Materials Co., Ltd., Yantai Sunny Rubber Co., Ltd., Yantai Sunny Hexing Environment Protection Equipment Co., Ltd., Huzhou Hehui Machinery Co., Ltd., etc, and Nuclear Industry Yantai Toncin Group Co. Ltd., Yantai Sunny Hexing Environment Protection Equipment Co., Ltd., Huzhou Hehui Machinery Co., Ltd., Yantai Xinghe Filtration Technology Co. Ltd. are belong to the solid-liquid separation equipment and technology filed, and their main products are solid-liquid separation products; Yantai Hejing Ceramic New Materials Co., Ltd. is an important crucible R & D and production enterprise in china; Yantai Sunny Rubber Co., Ltd. independently research and developed rubber dam, gas shield dam and other products, which are widely used in urban water conservancy construction, the technology level has reached the international advanced level. Toncin group currently own 5 state-level high-tech enterprises, 3 provincial-level enterprise technology centers, 1 provincial-level industrial design center, maintain 177 valid patents, including 38 invention patents, presided and participated in the formulation of more than 10 national standards and industry standards of the Horizontal Belt Type Vacuum Filter, Vertical Automatic Diaphragm Filter Press, Joint Resistance to Static Cutting Performance Test Methods of Rubber or Plastic Coated Fabrics and so on. The group has won the "China Patent Excellence Award", "National Key New Products", "Shandong Province Significant Energy-saving Achievement Award", "Shandong Province Technical Invention Award", "Shandong Province Science and Technology Progress Award" and a number of national and provincial science and technology award, undertaken a number of provincial science and technology, technical transformation special project of Shandong independent innovation achievements transformation major project and special funds project of Shandong industrial upgrading and synergism. The company has received the International Quality Control System Certification, Intellectual Property Management System Certification, Occupational Health Management System Certification and Environmental Management System Certification. The company has received the "Shandong Energy-saving Environmental Protection Demonstration Enterprise", "Shandong Intellectual Property Advantage Enterprise", " Observes Contracts and Keep Promises Enterprise", "China Patent Shandong Star Enterprise", " Shandong Management Innovation Excellent Enterprise ", "Advanced Enterprise of Excellent Performance " and other honorary successively.

FAQ

1.Q:Are you a manufacturer or trading company?

A: We are a manufacturer, we have rich experience in solid liquid industry for more than 20 years.We are the Horizontal belt vacuum filter and TC ceramic disc vacuum filter,HVPF tower press filter leader of China.

2.Q:Do you have minimum order quantity request?

A: for spare parts we have no MOQ,but for whole set equipment of course 1 set is the minimum.

3.Q:Do you have certificates?

A: Yes, we have CE, ISO,SGS.etc. certificates.

4.Q:Can you meet my special requirements for my products?

A: Yes, we have rich experience and we have a professional design team. We can provide different drawings according to your requirements.

5.Q:How to pay?

A:T/T is acceptable.

6.Q:What is the delivery time?

A: It depends on order quantities. Generally speaking, the delivery time will be within 2 months.

7.Q:How to pack the products?

A: We use standard export package. If you have special package requirements, we will pack as you required, but the fees will be paid by customers.

8.Q:How to install after the equipment arriving destination?

A: We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you.

9.Q:How long is the validity?

A:The validity is 12 months after installation.

-

Alcove filter press factory well glass plate, fiberglass filter plate

-

Cement sludge dewatering circular filter press with plunger pump

-

Durable, high quality water filtration membrane filter press with cloth cleaning drip tray

-

Ceramic round chamber filter press with favorable price automatic customized filter press

-

Machine builder’s automatic membrane PP filter press for breweries

-

Refinery Edible Oil Biodiesel Pressure Leaf Filter

-

Solid-liquid separation filter press for wastewater treatment

-

High pressure reinforced polypropylene filter press PP filter plate

-

Multi-layer stainless steel plate filter media

-

Oil wine clay ceramic automatic filter press concave plate filter press chamber filter press

Other Products

-

$42000.00 / set

$42000.00 / set -

$15000.00 / set

$15000.00 / set -

$2000.00 / set

$2000.00 / set -

$15000.00 / set

$15000.00 / set -

$50000.00 / set

$50000.00 / set -

$100.00 / square meter

$100.00 / square meter -

$100.00 / square meter

$100.00 / square meter -

$14000.00 / set

$14000.00 / set -

$15000.00 / set

$15000.00 / set -

$1000.00 / set

$1000.00 / set