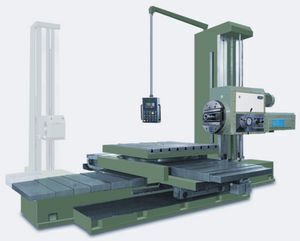

tpx6113 CNC thrust horizontal bore boring tools milling machine underground 280kn hdd horizontal bar XZ280

-

Supplier: SJR Machinery Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Selina Ren -

Price: $50000.00 /set -

Min. Order: 1 set

| After-sales Service Provided: | Engineers available to service machinery overseas,Field installation, commissioning and training; | Dimension(L*W*H): | mm; |

| Port: | Shanghai Port; | No. of Spindles: | SINGLE; |

| Positioning Accuracy (X axis) mm: | 0.005; | Production Capacity: | %; |

| Supply Ability: | 15 Set/Sets per Month; | Color: | as your requirement; |

| Warranty of core components: | 1 YEAR; | Warranty: | 1 YEAR; |

| Voltage: | 380V or as your requirements; | Applicable Industries: | Manufacturing Plant,Construction works ; |

| Table Size (mm): | 1100X960; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| CNC or Not: | normal; | Packaging Detail: | Standard Exporting Package; |

| Spindle Motor Power(kW): | 7.5; | Type: | HORIZONTAL; |

| Machinery Test Report: | Provided; | Weight: | 13000kg; |

| Weight (T): | 13 T; | Table Travel (Z) (mm): | 1400 mm; |

| Video outgoing-inspection: | Provided; | Max. Table Load(kg): | 2500; |

| Local Service Location: | Egypt,canada,algeria; | Travel (W-axis) (mm): | 600 mm; |

| Table Travel (Y) (mm): | 900 mm; | Place of Origin: | Liaoning China; |

| Marketing Type: | Hot Product 2019; | Positioning Accuracy (Z axis) mm: | 0.005; |

| Table Travel (X) (mm): | 900 mm; | Core Components: | PLC,engine,Bearing,Gearbox,MOTOR,PRESSURE VESSEL,GEAR,pump; |

| Key Selling Points: | Automatic; | Name: | cnc digital boring machinery; |

| Range of Spindle Speed(r.p.m): | 1000 r.p.m; | Condition: | New; |

| Showroom Location: | none; | Motor Power (kw): | 7.5; |

| Positioning Accuracy (Y axis) mm: | 0.005; | Certification: | CE&ISO9001; |

| Number of Axes: | 6; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Brand Name: | SMAC; |

cnc digital boring machinery

cnc digital boring machinery

1.High position accuarcy:most suitable for machining parts such as dies,drilling or boring

jigs and fixtures

2.wider range of application:drilling, boring, medium-load milling, scribing,scaling and measuring all are ok

3.various sizes of table:three standard sizes and much more amounts of size just as your requirement

https://smac.en.alibaba.com/product/60231742494-50021670/the_hot_sale_and_low_price_good_lathe_for_sale_CQ6263D_of_SMAC.html?spm=a2700.icbuShop.41413.10.1bf778a1kza9Il

DRO Horizontal boring machinery

Table:Optical sighting device is employed to achieve high positioning accuracy.

Spindle:Exhibits high rigidity on account of three-point stay,as well as high hardness and long service life thanks to surface nitrogen treatment

Face plate: is able to machine larger holes,external cutting,and grooves.

Main Technical Specification & Data

|

Model Item |

TPX611B |

TPX611B/2 |

|

Spindle diameter mm |

110 |

110 |

|

Spindle taper |

Morse No. 6 (ISO 7:24 NO. 50 as optional) |

Morse No. 6 (ISO 7:24 NO. 50 as optional) |

|

Max. spindle torque N.m |

1225 |

1225 |

|

Max. spindle thrust N |

12250 |

12250 |

|

Number of spindle speed |

22 |

22 |

|

Range of spindle speed rpm |

8 – 1000 |

8-1000 |

|

Power of main motor kW |

7.5 |

7.5 |

|

Max. facing head torque N.m |

1960 |

1960 |

|

Facing head diameter mm |

600 |

600 |

|

Range of facing head speed rpm |

4-200 |

4-200 |

|

Number of facing head speed |

18 |

18 |

|

Table working surface (LxW) mm |

1100*960 |

1100*960 |

|

Max. permissible load on table kg |

2500 |

2500 |

|

T-slot |

22 |

22 |

|

Number of T-slot |

7 |

7 |

|

X-axis travel mm |

900 |

1250 |

|

Y-axis travel mm |

900 |

900 |

|

Z axis travel mm |

1400 |

1400 |

|

W-axis travel (Spindle travel) mm |

600 |

600 |

|

U-axis travel (Facing slide travel) mm |

180 |

180 |

|

B-axis worktable rotary ° |

360 |

360 |

|

Min. distance between spindle axis and table surface mm |

0 |

0 |

|

Rapid travel (X/Y/Z/W) mm/min |

2500 |

2500 |

|

Rang of axes speed per spindle revolution (X/Y/Z/W) mm/min |

0.04-6/0.01-1.88 |

0.04-6/0.01-1.88 |

|

Feed range (X/Y/Z/W) mm/min |

-- |

-- |

|

Measurement system reading precision (X/Y/Z) (Z-axis measurement optional) mm |

0.005 |

0.005 |

|

B-axis measurement system reading precision (B-axis measurement optional) ° |

0.001 |

0.001 |

|

Overall dimensions mm |

4910X2450X2750 |

4910X2870X2750 |

|

Net weight of machine kg |

13000 |

14500 |

Standard Accessories

|

Item |

Remark |

|

X,Y axes DRO |

Newall brand (British) |

|

Worktable 4X90° worktable |

|

|

Facing head |

|

|

Adjusting pads |

Adjusting pads |

|

Turning tool holder for facing head |

|

|

ISO 7:24 NO.50 |

|

Professional Engineer Team Especially for the

cnc digital boring machinery

***********************************************************************

cnc digital boring machinery

1.More than twenty years experience of industry products

2.All models with CE , TUV, SGS , ISO9001/9002 OR other authority approved

3.High reputation around the world

4.Professional service and technology support

5.Competitive price with better quality, even the best

6.Final exported products would pass the strict test processing by 3rd international authority BIVAC

7.There is more exporting experience for 20years with our owned manufacture/company

cnc digital boring machinery

1.Your inquiry will be replied in 24 hours

2.Our manufacture/company has been a Gold supplier continuously in this Alibaba website for 6 years. And there is more industry technology experience for 20years with our manufactures

3.To offer free spare parts and service within one year of warranty

4.Technology Support Provide operation video for training

5.Professional after-sales service team

6.Give reasonable offers with the best quality

cnc digital boring machinery

1. Accept L/C, T/T ,D/A,D/Ptype of payments.

2. Regarding to the technical questions, pls contact our R&D.

3. Any question, call us or send email, we will try our best to satisfy you.

-

Portable cylinder boring machine T8014S with square stand

-

LTWL-50 Electric Portable Line Boring Welding Machine

-

TM807A motorcycle cylinder deburring and honing machine

-

Multifunctional 2 in 1 Portable Wire Drilling and Welding Machine, 220V or380v, 55~160mm

-

LD180A Valve Seat Boring Machine

-

SBM100 Motorcycle Boring Machine berco boring machines

-

Pneumatic Drilling Machine Drilling Machine ALLAME - FK-97

-

Portable line boring machine,onsite service,Joysung TDG50 line boring machine

-

Joysung Portable Line Drill for Heavy Equipment, Worn Excavator Arm

-

High quality low budget mobile portable line drill for excavator excavator

Other Products

-

$889.00 / set

$889.00 / set -

$40000.00 / set

$40000.00 / set -

$3700.00 / set

$3700.00 / set -

$22000.00 / set

$22000.00 / set -

$45000.00 / set

$45000.00 / set -

$17200.00 / set

$17200.00 / set -

$1100.00 / set

$1100.00 / set -

$5990.00 / set

$5990.00 / set -

$25000.00 / set

$25000.00 / set -

$24900.00 / set

$24900.00 / set