Punching machine for aluminium profile , Steel press, Holes stamping press

-

Supplier: Cangzhou Zhongtuo International Trade Co., Ltd. -

Region: Hebei, China -

Contact: Mr Cary xu -

Price: $24000.00 /set -

Min. Order: 1 set

| Power type: | Electric power; | Port: | XINGGANG PORT TIANJIN CHINA; |

| Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Food & Beverage Factory,farms,restaurant,HOME USE,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; | Place of Origin: | Hebei China; |

| Material thickness: | 0.3-1.5 mm; | Feeding type: | Automatic servo feeding; |

| Material: | stainless steel plate, galvanized plate, aluminium plate; | Payment Terms: | L/C,T/T; |

| Flattener: | 11 Rollers; | Packaging Detail: | NUDE PACKAGING IN 1*40 GP HIGH CUBE CONTAINER; |

| Warranty: | 2 years; | Decoiler: | 3T-5 T; |

| Voltage: | 380 V 50 Hz 3 Phrase; | Brand Name: | ZHONGTUO; |

| Material width: | Max 1250 mm; | Press tonnage: | 60T-200 T; |

| Supply Ability: | 30 Set/Sets per Month steel press, hole stamp; | After-sales Service Provided: | Online support,Field installation, commissioning and training,Field maintenance and repair service,No after-sales service,Video technical support; |

| Machine Type: | Hydraulic Scrap Shears; |

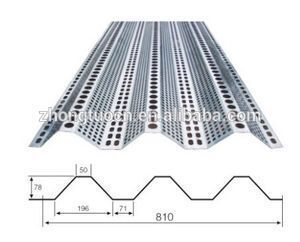

Punching machine for aluminium profile , Steel press, Holes stamping press

Material thickness : 0.3-1.5 mm

Material width : Max 1250 mm

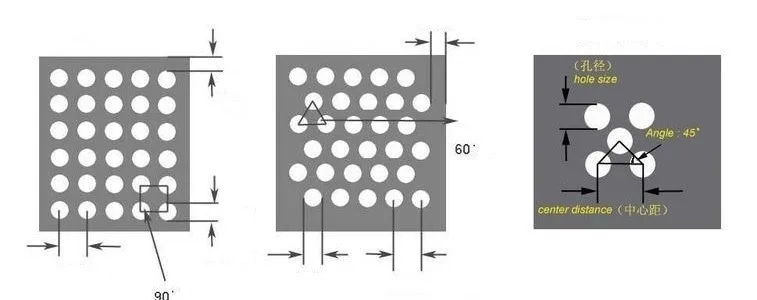

Holes density : 10 % - 25 %

Material : Stainless steel plate, Galvanized plate, Aluminium plate

Work flow:

1. Decoiler

| It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system. Decoiler type: Manual Loading capacity: 3T-5T Uncoiling width: Max 1250mm Inner diameter: 450-550mm |

2. Flattener | The coil from Decoiler is a little bit curves, the leveling system is to help make the coil straight, neat and clear. We will take 11 rollers, upper 5 rollers and down 6 rollers to level the coil. Leveling Rollers: 11 Rollers Diameter: 80 mm Leveling thickness: 0.3-1.5 mm Max leveling speed: 12 m/minute Drive type: Gear Motor power: 3 kw

|

3. Punching Machine

| 1. Press tonnage : 60T-200 T 2. Layout Form: Standing type 3. Size : 2.5*1.6*1.8 m (H*W*L) 4. Model No : J 21 (GANTRY TYPE) 5. Punching machine weight : 10 T 6. Power type: Electric power 7. Voltage: 380 V 50 Hz 3 Phrase 8. Feeding power: 1.5 kw 9. Main motor power: 18.5 kw 10. Slider trip: 30 mm 11. Slide Strokes: 55-60 times/minute 12. Punching speed: 1.5-2.5 meters /minute 13. Feeding type: Automatic servo feeding (Automatic stop when punching) |

4. Cutting Feeder | The machine automatically stops when cutting. After the cutting, the machine will automatically start. Feeding Rollers: 7 rollers Diameter: 80 mm Feeding thickness: 0.3-1.5 mm Max feeding speed: 12 m/minute Drive type: Gear Motor power: 4 kw

|

5. Hydraulic Cutting | Automatic cutting controlled by PLC. It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. The main machine automatically stops and then cutting. After the cutting, the main machine will automatically start. Material of blades: Cr 12 quenched HRC 58-60. Power supply : Hydraulic power Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, four hydraulic pipes and two sets of electromagnetism valves.

|

6. Receiving Table | Table for reception of the cut profiles with roller transporter allowing to unload the cut profile freely. Frame: Welded by square tube Size: 2.0 m*1.0 m*0.9 m (L*W*H) Supporter roller: ASTM 1045 with chrome Diameter of rollers: 55 mm Quantity: 3 Sets

|

Warranty |

1. One year warranty, whole life technical support. 2. Installation & adjustment : We can take a video for the customer and the customer can also come to our factory, we can train customer how to install and adjust the machine. 3. Oversea service: the buyer should charge of visa, return ticket, food and accommodation overseas and USD 50/person/day salary.

|

Cangzhou Zhongtuo cold roll forming machinery as a manufacturer since 1996,we are specialized in manufacturing color steel forming machine, light keel machine,

C&Z purline machine, Glazed tile forming machine, welded tube mill, stone coated roof production line, steel structural floor panel roll forming machine and so on.

We also have the derivatives and raw material. We real provide you one station, non-stop service.

Now our machine have been exported to 30 countries, such as Canada, South Korea, Russia, Holland, Sri Lanka, Malaysia, India, Brazil, etc.

Our company insists on the service aim: Quality First, Credit First. We believe that we can make the future cooperation and achieve win-win.

-

Scrap Metal Cutting Machine Hydraulic Shear Machine Hydraulic Metal Alligator Shears

-

Keshang Y10Y-1300T automatic hydraulic gantry shearing machine

-

Hydraulic Scrap Metal Baler Scrap Metal Ferroalloy Recycling Machine Q91y-1000W Gate Shearing Machine

-

Efficient Portable Electric Fishtail Machine Iron Art Hot Rolled Metal Fishtail Forging Equipment

-

BSGH 220V small wire crushing granulator cable wire recycling machine

-

Best Selling Horizontal Container Shears

-

Dinghua Recycling Equipment Scrap Automobile Shearing Machine

-

Hot selling European hydraulic crocodile shears AS-630 widely used in scrap metal recycling market

-

High quality hydraulic metal shears AS-60 for cutting various steel and metal

-

Alligator Hydraulic Scrap Metal Rebar Shearing and Cutting Machine for Scrap Aluminum/Copper Scrap Processing Equipment

Other Products

-

$70000.00 - $85000.00 / set

$70000.00 - $85000.00 / set -

$20000.00 / set

$20000.00 / set -

$5000.00 / set

$5000.00 / set -

$15000.00 - $23000.00 / set

$15000.00 - $23000.00 / set -

$27800.00 - $29800.00 / set

$27800.00 - $29800.00 / set -

$20000.00 / set

$20000.00 / set -

$2500.00 / set

$2500.00 / set -

$24000.00 / set

$24000.00 / set -

$14000.00 / set

$14000.00 / set -

$10000.00 / set

$10000.00 / set