Fast Delivery 20L 50L 100L 200L vacuum filtration glass reactor crystallization equipment for 99% pure CBD oil crystal

-

Supplier: Xi'an Toption Instrument Co., Ltd. -

Region: Shaanxi, China -

Contact: Ms Alice Shi -

Price: $17000.00 /set -

Min. Order: 1 set

| Automatic Grade: | Automatic; | Ports on cover: | 6 pcs; |

| Selling Units: | Single item; | vacuum pump: | optional; |

| Capacity: | 50L Filtration Crystallization Reactor; | Single package size: | 100X80X150 cm; |

| Working voltage: | 220V 60Hz 1 phase; | Packaging Detail: | standard wooden packing Base on your needs; |

| Reactor body volume: | 50L, glass material; | Certification: | ISO, CE; |

| Weight: | 80KG; | Place of Origin: | China; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; | Name: | Fast Delivery 20~50L Filtration Crystallization Reactor for CBD; |

| Stirrer motor: | 150W; | Power(W): | 150W; |

| Dimension(L*W*H): | 155*80*315CM; | Single gross weight: | 100.0 KG; |

| Warranty: | 1 YEAR; | Package Preview: | ; |

| Voltage: | 220V; | Brand Name: | TOPTION; |

| Condition: | New; | Ultrasonic power: | 2500W; |

| Type: | Reaction Kettle; | Applicable Industries: | crystalization filtration reaction; |

| Filter type: | Sand core filter plate with PTFE fixing gland; | Heating cooling system: | optional; |

Fast Delivery 20~50L Filtration Crystallization Reactor for CBDr

this nutsch filters is combined with our reactors perfectly.

The slurry is transferred into the filter reactor. The solid content in the slurry is held by the filter cloth under reactor body, while the filtrate runs away from outlet valve in the bottom plate and goes into right side collection flask.

Ultrasonic probe can help to mix the material with better effect.

and the stirrer inside reactor can mixing material and improve efficiency too.

The cake after filtration is removed easily from the cover or bottom by lowering and opening the glass filter vessel, which is fixed to the lifting device. The lifting device is also used to lower the bottom for accessing the filter cloth for cleaning and exchange.

1.Jacket glass reactor: 50L volume

2.Reactor cover port: total six ports: stirrer port, ph port, liquid feeding port, temp port, vent port, solid feed port.

3. with stirrer

4. with ultrasonicator to homogenize materials at the same time

5. with bottom filter plate, can filter material, and filter can be washed and clean easily with electric lift device.

6. with collection flask on right side to receive the material after filtration

7. with cold trap and collection flask to protect pump

8. Vacuum pump and heater or chillers are optional, base on your working condition.

10. Ultrasonic power 2500W

11. Sand core filter plate with PTFE fixing gland

12.Stirrer motor: 150W

13.Working temp: -80℃~ 250℃ (related heating cooling system should be prepared)

14. Working voltage: 220V 60Hz 1 phase

100L rotary evaporator for Ethanol removal (material concentration)

50L rotary evaporator for ethanol removal purpose

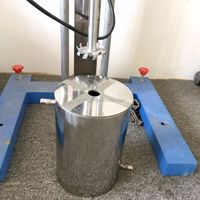

50L stainless steel vacuum filter, filter plate can be removable

20L nutsche Filter Dryer for material crystalization, filter, washing, drying purpose

Two stage molecular distiller short path for cbd oil distillation and purity

1. Provide you standard equipment, rotary evaporator, reactor, wiped film evaporators, filters, etc

2. design and customize equipment base on your needs totally.

3. provide you turnkey equipents for distillation area

4. provide you one stop equipment + delivery method

5. In time sales service for you at ay time.

Welcome to contact us, one-stop service can be provided for you at any time.

-

Laboratory bioreactor filtration crystallization single and double layer 20L 10L 5L 50L 100L 200L jacketed glass reactor

-

Hot sale new stainless steel industrial chemical decarboxylation reactor

-

Laboratory 20L Chemical Reactor Stainless Steel Reactor

-

500ml catalyst test equipment chemical pressure reactor

-

Reasonable price epoxy resin reactor production line

-

High-quality AC reactor 11kw 30A RACL 2%-30/11 three-phase AC line reactor

-

Bromine production line

-

Plant Direct Methanol Synthesis Reactor System with Insulation Function

-

Benchtop desktop small glass laboratory 5l 10l microbiology photo plant cell bacterial fermentation fermenter fermenter bioreactor

-

SS316 Jacketed container for laboratory dispensing mixing

Other Products

-

Crystallization reactor isolation 200L 200L jacketed stirred stainless steel crystallization reactor$31500.00 / set

Crystallization reactor isolation 200L 200L jacketed stirred stainless steel crystallization reactor$31500.00 / set -

$21800.00 / set

$21800.00 / set -

$8900.00 - $9800.00 / set

$8900.00 - $9800.00 / set -

$31500.00 / set

$31500.00 / set -

$770.00 / set

$770.00 / set -

$30.00 / set

$30.00 / set -

$21360.00 / set

$21360.00 / set -

$10680.00 / set

$10680.00 / set -

$26000.00 / set

$26000.00 / set -

$2700.00 / set

$2700.00 / set