Fully Automatic Cold Steel Strip Profile C Purlin Roll Forming Machinery

-

Supplier: Cangzhou Zhongtuo International Trade Co., Ltd. -

Region: Hebei, China -

Contact: Mr Cary xu -

Price: $17500.00 /set -

Min. Order: 1 set

| Cutting blade material: | Cr 12 with chrome; | Name: | Fully Automatic C Purlin Roll Forming Machinery; |

| Place of Origin: | Hebei China; | Weight: | 3-10tons; |

| Showroom Location: | Canada,United States; | After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; |

| Condition: | New; | Key Selling Points: | High Productivity; |

| Work Pressure: | 195 mpa---350 mpa; | Production Capacity: | 12-18 m/minute; |

| Supply Ability: | 30 Set/Sets per Month C U Purlin Roll Forming Machine; | Warranty: | 2 years; |

| Voltage: | 380v; | Size of container: | 40GP; |

| Control System: | PLC with touch screen; | Cutting type: | Hydraulic cutting; |

| Brand Name: | Zhongtuo; | Payment Terms: | L/C,D/A,D/P,T/T; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Dimension(L*W*H): | 8800mm*1800mm*1500mm; |

| Power(W): | 11KW; | Certification: | ISO9001/CE; |

| Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; | Local Service Location: | Canada,United States; |

| Lanugage system: | Chinese ,English ,Russian; | Packaging Detail: | 1. One 20ft container for loading one set machine with manual decoiler; 2. The whole Wiped Anti Rust Oil, PLC controller covered by foam film; 3. Spare parts and some small parts packed in plastic tooling box; 4. All components of the C Purlin Rolling Machine fixed by steel wire.; |

| Port: | Tianjin Port; | Roll material: | 45#; |

| Type: | Cold Rolling Mill; |

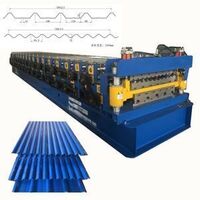

Fully Automatic C Purlin Roll Forming Machinery

Decoiler

Usage It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

1 Coil inner diameter 450-550mm

2 Coil max width 500mm

3 Max carrying capacity 3000kg

Entry leveling

1 Armed adjustable center of the forming rollers and of sufficient length to prevent lateral movement of the strip on its entry to flattener.

2 Entrance table-guide. adjustable

3 Entrance width range. 150-500mm

4 Entrance and guide roller. diameter is 110mm, material is sae1045.

RC48-52 surface with chrome.

Roll forming machine

1 Coil width. according to the profiles

2 Working speed.12-18 m/minute

3 Roller station. 12 stations

4 Material of roller. Cr 12 with chrome

5 Material of main shaft. 45

6 Main power. 11KW

7 Forming thickness. 1.5-2.0 mm

8 Transmission. Chain

9 Size of machine. about 8800*1800*1500 (mm) L * W * H

10 Weight. About 5..5T

11 Color of machine. blue and yellow

Shearing system

1 Cutting power by hydraulic. 5.5KW

2 Hydraulic working pressure. 20Mpa

3 Cutting after forming. Cut the sheet after roll forming to required length

4 Material of blade. Cr12 with heat treatment 58-60°

5 Length measuring. Automatic encoder

length measuring, brand. Omron

6 Tolerance of length. 3000mm+/- 1.0mm

Hydraulic station

1 Hydraulic power. 5.5kw

2 Working pressure. 20Mp adjustable

3 Solenoid valve. 3 groups

4 Hydraulic oil. 46 hydraulic oil

PLC station

1 The PLC powered by the software that controls the automation of the processes of forming cutting will be of

the latest technology available and allow the operator through a touch screen enter quickly and reliably all data to meet a predetermined production.

2 This automation software technology

should allow wider access to the source code so that can define and adjust their parameters according to needs of present and future production.

3 Voltage. 380 V, 50 Hz, 3Phase

4 Automatic length measurement

5 Automatic quantity measurement

6 Automatic punching distance

7 Length inaccuracy can be amended easily.

8 Unit of length. millimeter (switched on the control panel)

9 Language. English and Chinese

10.Brand. Panasonic

Run out table

It adopts welded steel and supported roller to transmit the products.

Our Service

1. Installation and training of machine manufacturer

a. If buyers visit our factory and check the machine, we will teach you how to install and use the roll forming machine for sale , and also train your workers/technician face to face.

b. Without visiting, we will send you user manual and video to teach you to install and operate.

c. If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

2. After Service of roll forming machine for sale

a. One year guarantee for whole roll forming machine for sale.

b. 24 hours technical support by email or calling

c. If there is any problem found of steel roof sheet roll forming machinery, we will repair roll forming machine for sale for free in one year.

-

Various narrow strip mills in steel re-rolling mills

-

120mm/160mm goldsmith sheet semicircle pattern wire roller silver gold electric mill for jewelry making machine

-

Continuous Casting Machine Rebar Manufacturing Machine Rolling Mill Production Line

-

Gear Ratio 1:2.5 Manual Wire Rod Tablet Press Jewelry Gold Jewelry Two Roller Rolling Mill Mill Jewelry

-

4" Benchtop Combined Plate and Wire Rod Mill Motorized and Manually Operated

-

Floor Standing Combined Plate and Wire Goldsmiths Jewelry Rolling Mills for Gold, Silver, Copper, Brass, Plate and Wire

-

6-high five-stand cold rolling mill/1450mm 6-high cold rolling mill

-

Indian Jewelry Gold and Silver Sheet and Wire Rolling Machine Precision Sheet and Wire Rolling Factory

-

1450 Aluminum Caster Casting Machine to make 1250mm wide and 6mm thick aluminum sheet rolling mill

-

High quality programmable screw machine EZSO GP-100T, max width 680mm, bending machine

Other Products

-

$70000.00 - $85000.00 / set

$70000.00 - $85000.00 / set -

$20000.00 / set

$20000.00 / set -

$5000.00 / set

$5000.00 / set -

$15000.00 - $23000.00 / set

$15000.00 - $23000.00 / set -

$27800.00 - $29800.00 / set

$27800.00 - $29800.00 / set -

$20000.00 / set

$20000.00 / set -

$2500.00 / set

$2500.00 / set -

$24000.00 / set

$24000.00 / set -

$14000.00 / set

$14000.00 / set -

$10000.00 / set

$10000.00 / set