JCT100 Coating Thickness Gauge

-

Supplier: Beijing Jitai Tech Detection Device Co., Ltd. -

Region: Beijing, China -

Contact: Ms Kathy Liu -

Price: $55.00 /set -

Min. Order: 1 set

| Minimum curvature radius convex: | 1.5mm; | Selling Units: | Single item; |

| Range: | 0~1500um; | Brand Name: | JITAI; |

| Size: | 155mm x 62mm x 35mm; | Model Number: | JCT100; |

| Power: | 4 x AAA batteries; | Single package size: | 22X15X6 cm; |

| Accuracy: | ±(2.5%+1um); | Resolution: | 0.1um/0.01mil; |

| Place of Origin: | Beijing China; | Minimum measuring area: | Diameter 6mm; |

| Weight: | 125g; | Package Preview: | https://sc02.alicdn.com/kf/HLB1KMK7LYvpK1RjSZFqq6AXUVXaW.jpg_640x640.jpg; |

| Units: | um, mil; | Single gross weight: | 1.5 KG; |

| Package Type: | Plastic box with paper package; |

Introductions:

The thickness gauge is used to measure the thickness of the plated and coated sheet on metal, e.g. paint/enamel/ chrome on steel, paint and anodizing coating on aluminum/copper.

The gauge takes the precision integrated probe, and uses principles of electro-magnetic induction and the eddy current effect, which automatically detects the attribute of substrates.

Application Field:

The Gauge is designed for non-destructively measuring the thickness of coating and painting. It is essential for material surface treatment and widely used in manufacturing industry, metal-processing industry, chemical industry, commodity inspection area, and also able to work steadily in the laboratory, workshop and outdoor.

Operating Principle:

The gauge adopts the principle of electromagnetic induction and eddy current effect. It has F probe and N probe.

F probe works on the magnetic induction principle and should be used for detecting the non-magnetic coating’s thickness such as chrome/copper/zinc/varnish/rubber on the iron/steel substrate.

N probe works on the eddy current principle and should be used for detecting the insulating coating’s thickness such as paint/anodizing/ceramics on the aluminum/copper/brass substrate.

Supply Information:

Package List:

u Coating Thickness Gauge

u Substrates

u Five Standard foils

u User Guide

Description:

1. Fe--Magnetic substrate indicator: Steel/Iron

2. NF--Non-magnetic substrate indicator: Copper/Aluminum

3. Auto power off flag, auto power-off in 5 minutes with no-operation

4. Battery level indicator

5. Measured Reading Display

6. SNG: Single Measurement Mode

7. CON: Continuous Measurement Mode

8. Unit: um, mil

9. ON/OFF

10. um/mil: Unit Switch Key, System Resetting Key( Press and Hold More than 3s )

11. ZERO: Clearing Display when SNG shows;

Using for calibration when CON shows.

12. MODE: Switch SNG/CON; SNG shows, Single-point Mode; CON shows, Continuous Mode

13. Anti-Skid Slot

14. Probe

Technical specifications

| Probe F | Probe N |

Principle | Magnetic Induction | Eddy Current |

Range | 0~1500um | 0~1500um |

Accuracy | ±(2.5%+1um) ±(2.5%+0.04mil) | ±(2.5%+1um) ±(2.5%+0.04mil) |

Resolution | 0.1um/0.01mil | 0.1um/0.01mil |

Calibration | Points: ZERO/50/100/250/500/1000um | |

Units | um, mil | |

minimum curvature radius convex: 1.5mm | ||

minimum curvature radius concave: 25mm | ||

minimum measuring area: Diameter 6mm | ||

minimum thickness of substrate | 0.5mm(0.02”) | 0.3mm(0.012”) |

Power | 4 x AAA batteries | |

Operation Environment | Temperature:0~40℃(32~104℉) Humidity:20%~90%RH | |

Size | 155mm x 62mm x 35mm (6.10” x 2.44” x 1.38”) | |

Weight | 125g(4.41oz) | |

-

0.001mm Micrometer Digital Dial Thickness Gauge for Plastic Film Leather Paper Inch Measurement Tool Thickness Gauge

-

The new LS220 coating thickness gauge can test non-magnetic and non-conductive coatings, with built-in integrated ruby tip probe Fe/NFe

-

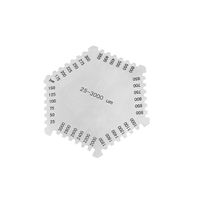

Stainless Steel Wet Film Thickness Gauge 25~3000um Hexagon Paint Brush Wet Film Thickness Gauge

-

2023 NEW BENETECH GT235 Car Paint Coating Thickness Gauge

-

Gm100 Digital LCD Ultrasonic Thickness Gauge Thickness Gauge Test Metal Width Gauge

-

ANGRY LR-FK202 High Precision Concrete Crack Width Measuring Instrument

-

Ultrasonic Metal Plastic Ceramic Glass Thickness Gauge MT160 4.5 Digit LCD EL Backlight Thickness Gauge

-

LS220B Linshang Bluetooth car detector car paint thickness gauge coating thickness gauge

-

CM-8825FN Coating Thickness Gauge F/NF Paint Thickness Gauge Range 0~1250

-

EC-900 Wide Range Paint Thickness Gauge Coating Thickness Gauge with Separate Probe

Other Products

-

$65.00 / set

$65.00 / set -

$175.00 / piece

$175.00 / piece -

$198.00 / set

$198.00 / set -

$135.00 / set

$135.00 / set -

$175.00 / set

$175.00 / set -

$400.00 / set

$400.00 / set -

$100.00 / set

$100.00 / set -

$100.00 / set

$100.00 / set -

$700.00 / set

$700.00 / set -

$1200.00 / set

$1200.00 / set