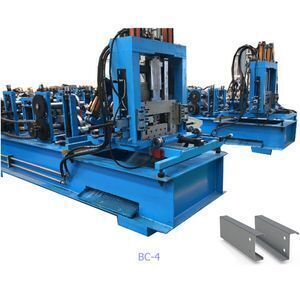

Cheaper CZ Purlin Roll Forming Machine Steel Frame and Purlin Making Machines

-

Supplier: Anping Baochuan Wire Mesh Products Co., Ltd. -

Region: Hebei, China -

Contact: Ms Tianhua Zhang -

Price: $32999.00 /set -

Min. Order: 1 set

| Material: | AI/GI/PPGI/Steel; | Frame type: | Memorial arch frame; |

| Work Pressure: | 235---550Mpa; | Key Selling Points: | Long Service Life; |

| Power(W): | 7.5KW; | Lanugage system: | Chinese ,English ,Russian (customized); |

| After-sales Service Provided: | Online support,Video technical support; | Production Capacity: | 8-12m/min; |

| Weight: | 9Tons; | Condition: | New; |

| Production Capacity: | 8-12m/min; | Voltage: | 380V/ 440V/50HZ/3Phase; |

| Voltage: | 380-440; | Dimension(L*W*H): | 13000*1300*1100; |

| Model Number: | CZ purlin MACHINE; | Applicable Industries: | Machinery Repair Shops; |

| Certification: | ISO 9001; | Place of Origin: | China; |

| Brand Name: | Baochuan; | Material thickness: | 1.5-3.2MM; |

| Warranty: | More than 5 years; | Control System: | PLC with touch screen; |

| Dimension(L*W*H): | 11000*1300*1100; | Type: | Steel Frame & Purlin Machine; |

| Weight: | 9Tons; | Packaging Detail: | Packaging Details: main machine is naked and the computer control box is packed by carton box Delivery Detail: 30days after receiving the deposit 1.We have professional technicians for loading Guaranteed the goods load into container without any damage. 2. Transportation : Machines need one 40 feet container to hold 3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.; |

This is our other wire mesh machine:

CZU Purlin Roll Forming Machine

SALIENT FEATURES

Purlin Roll Forming Machine can form hot/cold rolled steel strip and get various specification purlins: C Purlin, Z Purlin, M Purlin, U Purlin.The forming speed can reach to 30m/min .It is fully automatic cold forming line for steel structure industry.

Inline flexible punching system integrated.

C and Z Profile changeovers automatically.

Dimension changeovers automatically.

Material thickness Guage 1.5mm~3.5mm

Straightening unit adapted to easily rectify the distortion and straightness from the bias of material.

Interchangeable C/Z purlin Roll Forming Machine manufactures both Cee & Zed shaped section channels with shapes and sizes quick changed by PLC control.

For a steel structural building project, people always use Cee and Zed steel purlins (different web sizes and different flange sizes).

Production Characteristic and Use of CZU Purlin Roll Forming Machine

One machine can produce differenct C/Z Purlins throught automatically stepless adjustment, when producing different profiles, no need to change forming rollers. In the process, machine adopt automactic control model, it can make auto pumch, cut, forming based on inputting length of purlin, holes distance, quantity, etc.

One side fixed, the other side adjustable

Manual or motorized servo positioning of moveable head

Designed for efficient production of various panel widths

It is quick and easy to operate the machine, high production efficiency, forming speed up to 20m/min.

This machine can produce C , Z, U three profiles, through the exchange side of the roller up and down position to achieve C , Z, U purlin conversion, just need less than one minute to achieve.

TECHNICAL PARAMETERS

Main Specifications of Purlin Roll Forming Machine

Material: G.I Coil, Carbon steel, Hot Rolled, Cold Rolled

Material Thickness:1.5-3.5mm

Forming Speed: 12-15 m/min

Landscape orientation adjustment range of hole distance : 45-500mm

Forming Stations: 17 Main rollers

Leveling Stations: 7

Feeding Stations: 2

Main Power: 22KW

All the PLC, we will make three country language

WHY CHOOSE US

Products Features:

1. To meet the requirements of the main steel structure rapid construction, to provide a firm platform in a short period of time, and the use of multi-layer laying of steel plate, layered pouring concrete slab construction.

2. The use of floor boards as concrete slab tensile reinforcement, but also improve the floor stiffness, saving the amount of steel and concrete.

3. The embossing of the surface of the profiled slab causes the maximum binding force between the slab and the concrete, so that the two are integrated with the stiffener to make the slab system with high strength.

4. Under cantilever conditions, the length of the floor slab suspended only as a permanent formwork can be determined according to the cross-sectional characteristics of the floor slab.

Our Service:

1. Technology:We have centers and innovative designing teams for different kinds of production lines.

2. After Sale Service:Warranty period 1 year , after this period , we are willing to give help if customer needs accessory . The real cooperation will not end at the delivery . we believe that satisfied after sale service means a lot.

3. Inspected by the Sellers:After completing the manufacturing and assembling of the equipments, we will test the machines and commissioning in the workshop.

4. Inspected by the Buyers:After confirmation of a sound work of the line, we will invite our customer to send their representatives to inspect the production lines in our factories.

This is our client

If you want know more about the machine or want know the quotation, please check us now

1 Q:How to place an order?

A: Inquiry---confirm the profile drawings and price----confirm the PI---arrange the deposit or L/C---then OK

2 Q:Can you make the machine according to my design or photo type?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us

3. Q: How can we be assured that you will deliver us quality machine with spare parts?

A:1. Customers to send the technical people to our factory for checking the quality.

2. We can send the technicians to the buyer`s factory for the installation of the machine.

-

High speed metal roll forming machine and track

-

c light keel forming frame cad light steel machine

-

House light steel villa light steel keel forming machine

-

Electrical Cabinet Shelf Roll Forming Machine Using Elephant Roll Forming Technology

-

Light steel keel equipment keel rolling forming frame dividing machine

-

Popular c panel channel steel stud light weight keel equipment roll forming machine

-

metal frame for making drywall drywall, stud rolls, cu shaped light keel forming machine

-

Precast Concrete Fence H Beam Making Machine After Precast Concrete Fence

-

Gypsum Board Ceiling Steel Fur Channel Forming Machine Omega Channel Forming Machine

-

PLC controlled steel CZ purlin roll forming machine for quick replacement

Other Products

-

$6999.00 - $7999.00 / set

$6999.00 - $7999.00 / set -

$6999.00 - $8599.00 / set

$6999.00 - $8599.00 / set -

$2399.00 / set

$2399.00 / set -

$3913.00 / set

$3913.00 / set -

$4999.00 / set

$4999.00 / set -

$89999.00 / set

$89999.00 / set -

$8999.00 / set

$8999.00 / set -

$8699.00 / set

$8699.00 / set