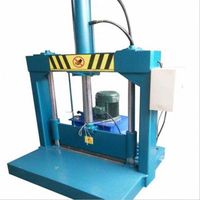

rubber cutting machine / rubber powder making machine / rubber powder production line

-

Supplier: Qingdao Guangyue Rubber Machinery Manufacturing Co., Ltd. -

Region: Shandong, China -

Contact: Mr daguang qiu -

Price: $20000.00 /set -

Min. Order: 1 set

| Keywords: | Waste tire recycling system | Cutting stroke (mm): | 600 |

| model: | GY-600 | bushing: | Nylon bushing, copper bushing, ball bearing bushing |

| Showroom location: | UK, US | Voltage: | 220V/380V |

| Year: | 2024 | type: | tire machine |

| Brand name: | Guangyue/OEM | Main selling points: | Long service life |

| power supply: | Hydraulic | Applicable industries: | Manufacturing plants, machinery repair shops |

| Core components: | engine | Core component warranty: | 3 years |

| Video outbound inspection: | if | Mechanical test report: | if |

| Warranty: | 2 years | Power (kW): | 5kW |

| Cutting force (T): | 100 tons | Gap adjustment: | Electric and manual |

| Dimensions (length*width*height): | 3950*1800*1780 | Roller material: | cast iron steel |

| Product name: | Rubber cutting machine/rubber powder making machine | Health) status: | new |

| Origin: | Shandong Province, China | Weight (kg): | 1500kg |

| Payment terms: | L/C, Western Union, T/T, MoneyGram | Tire machine type: | tire recycling machine |

Rubber cutting machine/rubber powder making machine/rubber powder production line

Application of tire retreading machine

They are used to recycle scrap tires to create rubber powder

1-1. Ring cutter

|

thing |

Specification |

|

Motor power |

5.5 |

|

Main screw speed |

46.8 rpm |

|

tire maximum diameter |

1200mm |

|

aspect |

1100*900*1700mm |

|

Purpose: Cutting steel rims from tires

|

|

1-2. Circle making machine

|

thing |

Specification |

|

Motor power |

15kW |

|

Front roller linear speed |

15.5 meters/minute |

|

speed ratio |

1.1 |

|

aspect |

1520*1150*12101mm |

|

Purpose: Separate the steel ring from the rubber after step 1. |

|

1-3. Slitting machine

|

thing |

scope |

|

Motor power |

5.5kW |

|

Disc diameter |

380mm |

|

Speed |

18.4 rpm |

|

aspect |

1290*870*1550 |

|

Purpose: Cut old tires into strips

|

|

1-4. Dicing machine

|

thing |

Specification |

|

Motor power |

11 kilowatts |

|

Main screw speed |

420 rpm |

|

Tool outer diameter |

200mm |

|

aspect |

1130*830*1100 |

|

Usage: Cut strips into chunks |

|

1-5.Tire crusher

Purpose:

Crush the rubber block into rubber powder and granules.

|

thing |

XKP-560 |

|

Front roller diameter (mm) |

560 (smooth) |

|

Back roller diameter (mm) |

510 (slot) |

|

Working length(mm) |

800 |

|

Front roller linear speed (m/min) |

25.56 |

|

ratio |

1:1.30 |

|

Maximum gap (mm) |

15 |

|

Capacity (kg/hour) |

600-800 |

|

Motor power(kw) |

75 |

|

Dimensions (length*width*height) (mm) |

5064*2284*1978 |

|

Weight (kg) |

18000 |

1-6.Large-scale conveying equipment

Motor power: 2.2kw

Conveyor length: 8000mm

Belt width: 550mm

Speed: 40m/min

Transport the rubber pieces to the crusher.

1-7.Small conveying equipment

Motor power: 1.1kw

Conveyor length: 3m

Belt width: 400mm

Speed: 30m/min

1-8. Large magnetic separator

Motor power: 1.1kw

Belt width: 400mm

Speed: 30m/min

Purpose: Separate small pieces of steel from rubber powder.

1-9.Small magnetic separator

Motor power: 1.1kw

Belt width: 400mm

Speed: 30m/min

1-10. Large vibrating screen

Working length: 6000mm

Working width: 1000mm

Motor power: 7.5kw

Size: 7800*1250*600mm

Purpose:

(1) Separate the rubber particles and powder, send the particles back to the crusher, and send the powder to the magnetic separator through a small conveyor belt.

(2) Separate textile cords from rubber powder

1-11.Small vibrating screen

Working length: 3000mm

Working width: 1500mm

Motor power: 3kw

1. Professional manufacturer with professional production team and technical support

Top sales teams communicate with customers via email, phone, and in person.

2. Professionally explain the machine (technology, application, usage guide, etc.) to customers

The best after-sales service - track the production status throughout the entire process, provide machine packaging photos, and track the customer's operation and usage to prevent problems.

3. Reasonable price

4. Flexible delivery time

5. More than 30 years of experience in export capabilities

-

Automatic tire slicing and cutting machine tire recycling machine YG1200 tire cutting machine factory sale

-

Industrial Rubber Processing Machinery Gravel Cutting Machine/Hydraulic Rubber Pack Cutting Machine

-

Automatic rubber strip cutting machine slitting machine rubber cutting slitting machine

-

Efficient OEM Ultrasonic Sewing Machine Woven Bag Sewing Machine Non Woven Bag Sewing

-

Waste Rubber Cutting Machine/ Used Tire Cutting Machine/ Used Tire Recycling

-

Automatic rubber sheet slitting machine, rubber slitting machine, rubber slitting machine

-

Single Knife Hydraulic Baler/Rubber Cutting Machine

-

Silicone Rubber Cutting Machine, Silicone Rubber Cutting Machine, Rubber Slitting Machine

-

Rubber Press Plastic Rubber Machinery Rubber Slitting Machine

-

Hot selling high efficiency baler cutting machine rubber cutting machine

Other Products

-

$5000.00 - $6000.00 / set

$5000.00 - $6000.00 / set -

$10200.00 - $13000.00 / set

$10200.00 - $13000.00 / set -

$5800.00 - $6000.00 / set

$5800.00 - $6000.00 / set -

$5000.00 - $6000.00 / set

$5000.00 - $6000.00 / set -

$2000.00 / set

$2000.00 / set -

$5500.00 / set

$5500.00 / set -

$8000.00 / set

$8000.00 / set -

$1000.00 / set

$1000.00 / set -

$5000.00 / set

$5000.00 / set -

$18000.00 / set

$18000.00 / set