Rubber grinder made in China

-

Supplier: Qingdao Guangyue Rubber Machinery Manufacturing Co., Ltd. -

Region: Shandong, China -

Contact: Mr daguang qiu -

Price: $6000.00 / 1 - 1 sets

$5800.00 / >=2 sets -

Min. Order: 1 set

| Applicable industries: | Hotels, clothing stores, building materials stores, manufacturing plants, machine repair shops, household, retail, food stores, print shops, construction projects, energy and mining, food and beverage stores, others, advertising agencies | Certification: | ISO9001:2008/CE/S.GS |

| Roller bearing: | Dry grease lubrication/thin oil lubrication | Health status: | new |

| After-sales service provided: | Overseas service machinery | Video outbound inspection: | if |

| Supply capacity: | 30 sets of discussions per month | brand: | Kozuki |

| Weight (kg): | 4000kg | Voltage: | 220v/380v/440v/460v according to customer requirements |

| seat: | Cast or weld | Three types of shrubs: | Nylon bushing/copper bushing/ball bearing |

| history: | More than 30 years of expertise | Drum diameter: | 450mm |

| Main selling points: | High security level | Warranty: | 2 years |

| Packaging details: | Bulk in 20/40ft containers or as per your needs | Post-warranty service: | On-site maintenance |

| Core component warranty: | 3 years | Roll diameter (mm): | 450mm |

| Mechanical test report: | if | Roll length (mm): | 1800mm |

| port: | Qingdao | Showroom location: | Morocco, Argentina, South Korea, Chile, United Arab Emirates, Algeria, Kazakhstan, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Malaysia, Australia, Turkey, United Kingdom, United States, Italy, France, Vietnam, Philippines, Saudi Arabia, Indonesia, Russia ,Thailand |

| Dimensions (length*width*height): | 4350*1850*1780mm | Core components: | PLC, engine, bearing, motor, pressure vessel, gear |

| Rolls-Royce: | Chilled cast iron roller | payment terms: | Letter of credit, wire transfer |

| color: | based on customer's needs | Place of origin: | Shandong Province, China |

| Year: | Products after order |

|

rubber mill With CE, SGS, ISO

|

||||||

|---|---|---|---|---|---|---|

|

Alias: Rubber mixing machine. Open rubber mixing mill, open rubber mixing mill, rubber open mixing mill, two-roller rubber open mixing mill, Two-roller open mill.

|

||||||

|

1. Certification:watte hasISO9001:2008, SGS, CEQuality standards and provide various certifications as per customer requirements Requirements: Such as CO, CIQ, SASO, etc. |

||||||

| 2. Main features: | ||||||

|

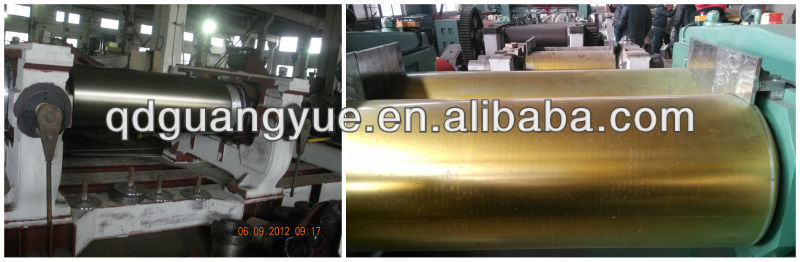

(1) Roll material: cast iron alloy (LTG-H), quenched and precision machined, hardness HS 75. (2) Bearings: double row rolling bearings, reducing energy consumption by 30%. (3)Roll gap adjustment: electric automatic or manual (4) Voltage: variable frequency speed regulating motor (5) Reducer: airtight oil-immersed type, ZSYE reducer (there are many options: hard tooth surface, gear reducer. The price is different), virtually noiseless, safe |

||||||

|

3. Coil material: |

||||||

| The roller is made of cast iron alloy (LTGH),its surfaceyes75HS, back Quenching andPrecision Machiningit is better than

Other companies, (usually 72HS). The working surface is well ground and machined. tSmooth surface, uniform temperature, high hardnessandlong lasting.

|

||||||

|

4. Motor: |

||||||

|

We have always used electrical components from Omron, Siemens and other brands, and you can also choose ordinary brands. All motors are high quality and High efficiency, energy saving, low noise and small vibration

|

||||||

|

5. Roll gap adjustment: |

||||||

|

The roller gap adjustment is realized manually or electrically, with high precision and sensitivity.

|

||||||

| 6. Reducer: | ||||||

|

The reducer has a hard tooth surface, level 6 accuracy, no noise, no vibration, safety, and higher transmission efficiency. (There are many options with different prices), gear box (double output shaft transmission)

|

||||||

| 7. Framework: The base is welded as a whole frame, which is easy to install and maintain. | ||||||

|

8. Stock bending machine:The film and knife can be cut and assembled directly as needed to improve the mixing quality. Reduce energy consumption. |

||||||

|

9. Emergency braking device: |

||||||

| The machine is also equipped with an emergency braking device. In the event of an emergency, just pull the safety lever Or press the emergency button and the machine will stop immediately. Safe and reliable.

|

||||||

| 10. Cooling system:(with swivel joint andExternal tapping) | ||||||

|

Universal swivel joint with internal nozzles, hoses and headers. The pipeline is completed up to the supply pipe terminal, where Energy consumption is reduced by 30% and the efficiency is high. |

||||||

|

11. Automatic grease lubrication system and supporting bearings |

||||||

| 12. others: | ||||||

|

us,Qingdao Guangyue Rubber Machinery Manufacturing Co., Ltd.Build high-quality rubber machinery, from materials to production,We use goodHigh-quality materials, fullymanagement system, returnExcellent after-sales service,we hope become onereliablefactoryFor you!

1. Professional manufacturer with professional production team and technical support 2. Our well-trained professional engineers and staff can provide exclusive and unique solutions to our customers. the best After-sales - Track the production status throughout the process, provide machine packing photos, and track the operation status Customer usage when issues arise. 3. Reasonable price and flexible delivery time 4. More than 30 years of experience in export capabilities

|

||||||

|

13.technologyparameter: |

||||||

| Version | XK-160 | XK-250 | XK-300 | XK-400 | XK-450 | XK-560 |

| Roll diameter (mm) | 160 | 250 | 300 | 400 | 450 | Chapter 560 |

| Roll length (mm) | 320 | 620 | 750 | 1000 | 1200 | 1530 |

| Front roller surface speed (m/min) | 8.89 | 15.3 | 15.1 | 18.65 | 24.32 | 27.72 |

| friction ratio | 1:1.35 | 1:1.1 | 1:1.27 | 1:1.27 | 1:1.27 | 1:1.2 |

| Maximum nip (minimum) | 4 | 8 | 8 | 10 | 15 | 15 |

| Feeding amount per amount (kg) | 1-2 | 10-15 days | 15-20 days | 18-35 | 25-50 | 35-50 |

| Power (kW) | 5.5 | 18.5 | number 22 | 37 | 55 | 90 |

| Dimensions (length*width*height) | 1160*920*1370 | 3120*1322*1500 | 3580*1550*1695 | 4350*1850*1780 | 5670*2390*1670 | 5845*2284*1978 |

| Weight (kg) | 1000 | 4000 | 5200 | 7800 | 12000 | 23000 |

|

Vietnam orders XK-160 laboratory rubber mixing machine

|

||||||

|

xk-400 mixer UK customer order

|

||||||

|

XK-450 rubber mixing machine exported to Türkiye

|

||||||

|

XK-560 rubber mixing machine exported to Ethiopia

|

||||||

|

Certificate

|

-

CE standard two-roll rubber mixing machine

-

Two-roll mill, two-roll rubber mill, rubber two-roll mill

-

Mini Rubber Sheet Rolling Machine, Rubber Silicone Mixing Machine, Rubber Rolling Machine

-

Laboratory double-roll rubber and plastic color mixing machine, high quality and low price

-

kneading machine, rubber kneading machine, kneading machine

-

XKP-560 Double Roller Rubber Crusher Waste Tire Rubber Crusher

-

EVA&Rubber Kneader

-

Factory direct sales of automatic material turning rubber and plastic PVC mixing electromechanical heating double-roller rubber mixing machine

-

New Double Roller Rubber Mixing Machine

-

High Quality Open Mill/Two Roll Mixer/Rubber Mixer

Other Products

-

$20000.00 / set

$20000.00 / set -

$5000.00 - $6000.00 / set

$5000.00 - $6000.00 / set -

$10200.00 - $13000.00 / set

$10200.00 - $13000.00 / set -

$5000.00 - $6000.00 / set

$5000.00 - $6000.00 / set -

$2000.00 / set

$2000.00 / set -

$5500.00 / set

$5500.00 / set -

$8000.00 / set

$8000.00 / set -

$1000.00 / set

$1000.00 / set -

$5000.00 / set

$5000.00 / set -

$18000.00 / set

$18000.00 / set