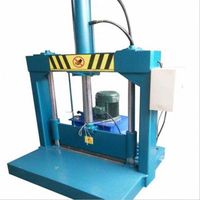

Rubber Press Plastic Rubber Machinery Rubber Slitting Machine

-

Supplier: Xiamen Yamajia Technology Co., Ltd. -

Region: Fujian, China -

Contact: Mr yuming he -

Price: $6349.00 / 1 - 49 sets

$4127.00 / 50 - 99 sets

$3810.00 / 100 - 499 sets

$3286.00 / >=500 sets -

Min. Order: 1 set

Product details

| Main selling point: | multifunctional | Automatic weighing: | Yes |

| Automatically correct material weight: | Yes | year: | 2022 |

| Marketing Type: | New Products 2022 | brand: | New Chen Qian |

| Custom features: | Yes | Power (kW): | 1.5kW |

| model: | XCQ-QT-N/XCQ-QT-C | Core Components Warranty: | 1 year |

| Weight (kg): | 288 kg | product name: | Rubber intelligent weighing cutting machine |

| Supply capacity: | 300000 pieces/month | Material shortage warning function: | Yes |

| Dimensions (L*W*H): | 1150*900*1400MM | Showroom location: | Do not |

| Automatic trimming of trim margins: | Yes | Applicable industries: | factory, other |

| Warranty: | 1 year | place of origin; place of origin: | China |

| Cutting speed: | 1.5 seconds/pc | Mechanical test report: | if |

| Health status: | new | Remote cloud monitoring: | Yes |

| Automatic trimming: | Yes | Cutting force (T): | 1 ton |

| Core components: | Programmable controller, motor, lead screw, steel | Video external inspection: | if |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram | Voltage: | 220V/50HZ |

| Energy source: | electric | Product qualification accuracy: | 100% |

Recruit global distributors |

Specification

thing | value |

energy source | electric |

Health status | new |

Video checkout | if |

Mechanical Test Report | if |

Marketing Type | New Products 2022 |

place of origin; place of origin | China |

brand | New Chen Qian |

model | XCQ-QT-N |

Voltage | 220V/50HZ |

Size (L*W*H) | 1150*900*1400MM |

year | 2022 |

Power (kW) | 1.5kW |

Weight (kg) | 288KG |

Applicable industries | factory, other |

product name | Rubber intelligent weighing cutting machine |

Product qualification accuracy | 100% |

cutting speed | 1.5 seconds/pc |

automatic weighing | Yes |

Automatically correct material weight | Yes |

Material shortage warning function | Yes |

Automatic trimming | Yes |

Automatically trim trim margins | Yes |

Remote cloud monitoring | Yes |

custom function | Yes |

Product Description

The difference between the rubber intelligent weighing cutting machine and the old model

Compared | old model | new model |

convenient | 1. Most of the old equipment does not have automatic weighing function, and manual weight sampling is required The material is cut out; the feeding distance of the equipment is corrected by the sampling results, which requires multiple confirmations Second-rate. 2. It is necessary to manually tear off the oiled paper in advance, or check whether the oiled paper enters the equipment material during operation. 3. Need to manually confirm whether the quantity is sufficient 4. When the customer's product Two pieces of adhesive material are needed at the same time, only the first piece can be cut first, and then cut The second weight can be reduced. 5. Some old models are sticky and need to be stored separately, otherwise they will stick At the same time, most of the old models are only suitable for continuous cutting, otherwise it will cause poor accuracy, Increase labor cost | 1. Our company has its own automatic weighing function, which can predict the change of product thickness in advance and automatically adjust Feeding distance to adjust weight, responsive. 2. With automatic oil paper roll function; easy to roll and draw Oil paper. 3. With automatic counting function. 4. It can be set to cut two different weights and different quantities of adhesive 5. The single-mode cutting mode can be set, the specified number of cuts can be cut, and the Drop the material and continue to cut the second mold, which can be used with the vulcanizer to solve the problem of viscose Material. |

accuracy | 1. The method of manual sampling determines the risk of defective products at the sampling interval. 2. Manual method Adjusting the feeding distance corrected the weight error to a great extent, but the adjustment frequency was too infrequent, resulting in at low pass rates. 3. The deviation value of glue cut out by most of the old equipment is relatively large to the process. | 1. Each strip is weighed, and the accuracy of qualified strips can reach 100%. 2. Using PID adjustment algorithm Dynamically adjust weights in real time, each weight converges to a set value, predicting product thickness changes progress. 3. Adopt 0.01g precision sensor to achieve high-precision weighing, control the tolerance range, and improve product quality. |

Safety | 1. Manual sampling is to take out the product from under the blade, which is likely to cause safety accidents. | 1. Automatic weighing, automatic screening of qualified and unqualified materials to eliminate hidden quality risks Manual operation. |

Our factory

Certificate

VIEW MORE

You may like

-

rubber cutting machine / rubber powder making machine / rubber powder production line

-

Automatic tire slicing and cutting machine tire recycling machine YG1200 tire cutting machine factory sale

-

Industrial Rubber Processing Machinery Gravel Cutting Machine/Hydraulic Rubber Pack Cutting Machine

-

Automatic rubber strip cutting machine slitting machine rubber cutting slitting machine

-

Efficient OEM Ultrasonic Sewing Machine Woven Bag Sewing Machine Non Woven Bag Sewing

-

Waste Rubber Cutting Machine/ Used Tire Cutting Machine/ Used Tire Recycling

-

Automatic rubber sheet slitting machine, rubber slitting machine, rubber slitting machine

-

Single Knife Hydraulic Baler/Rubber Cutting Machine

-

Silicone Rubber Cutting Machine, Silicone Rubber Cutting Machine, Rubber Slitting Machine

-

Hot selling high efficiency baler cutting machine rubber cutting machine

Related Search

open type plastic rubber mixing machine suppliers

plastic rubber kneader machine

rubber vulcanizing machine

rubber coating machine

rubber extruding machine xj 115

rubber making machines

safe rubber cutter machine

water cooling waste tyre/rubber pyrolysis machine/

banbury rubber mixer machine

rubber banbury machine banbury