Chinese supplier of full automatic tennis ball making machine

-

Supplier: Guangzhou Jasu Machine Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Peter lee -

Price: $10000.00 /unit -

Min. Order: 1 unit

| Operating mode: | step | application: | bottle |

| Dimensions (L*W*H): | 3.8X1.5X3.2M | Year: | 2020 |

| port: | Guangzhou, Shenzhen | machine: | Injection Blow Molding Machine |

| Plastic processing: | pet | Certification: | CE |

| Warranty: | 1 year | Voltage: | 380V 50Hz |

| Origin: | Guangdong, China | After-sales service provided: | Engineers available to repair machinery overseas |

| Supply capacity: | 50 injection blow molding machines per month | strength: | 18.5 kW |

| Core components: | Programmable controller, motor | Showroom location: | not any |

| Blow molding type: | injection blow molding | blow: | injection blowing |

| Main selling points: | energy saving | Health status: | used |

| After Warranty Service: | Video technical support, online support | Packaging Details: | Injection Blow Molding Machine: Plastic Woven Film |

| Marketing Type: | 2020 New Products | payment terms: | L/C, Western Union, T/T |

| Chamber number: | 8 cavities | weight: | 5 tons |

| brand: | Jasu | Computer material: | Diffusion type |

| automatic: | Yes | automation: | automatic |

| Core component warranty: | 1 year | Video outbound inspection: | if |

| Local service locations: | not any | Mechanical test report: | if |

| Hollow part volume: | not any | Station No: | 3 stations |

| Applicable industries: | Food and Beverage Factory, Others | Material: | Polycarbonate, polystyrene, acrylic |

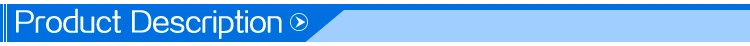

JASU one-step blow molding machine includes

Injection blow molding machines and injection stretch blow molding machines.

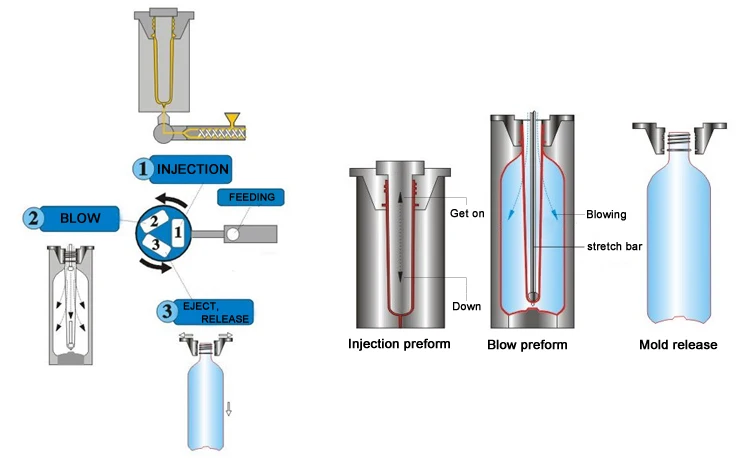

The machine is divided into three stations: injection of preforms, blow molding/stretch blow molding and product release. The raw material is injected into the preform from the hopper to the injection screw; the plate rotates the preform to the blow molding/stretch blow molding station by its own heat, without any reheating blow molding,

Then the product rotates to the release station and descends, which is a fully automatic cycle rotation working mode.

Compared with the traditional blow molding machine, JASU one-step blow molding machine has many advantages, first, no reheating is required, the preform itself is heated during injection blowing, highly energy-saving and shortens molding time, and more importantly, one-step machine cuts off The transfer process of the two-step blow molding machine is avoided, and the pollution caused during the transfer process is avoided, especially for medicine and food containers, which saves labor and transfer costs, reduces production costs, and improves product competitiveness.

Models ISB800-3 and ISB800A-3 (larger sizes)

Suitable for PC, PS, PMMA lampshades, LED lampshades, Christmas flashing lights, garden lights and street lights.

Suitable for PET high transparency, thinner wall, cosmetic bottle 10ml to 500ml, PET wide neck jar, PET medicine bottle

Suitable for PP high transparent, baby feeding bottle, sports feeding bottle

Compatible with PCTG, Tritan drinking water bottles, sports bottles.

Mold and tooling, we have our own mold workshop, advanced CNC machine tools and intelligent design engineers, we can handle products of different materials and sizes from different customers all over the world.

Auxiliary machines, we will equip you with the necessary high-quality auxiliary machines to ensure the smooth progress of the production plan, and we can provide you with one-stop service.

|

Model |

ISB 800-3 | |

| injection model | ||

| Screw diameter | 40mm | |

| Screw aspect ratio | 20.5:1 | |

| Screw speed | 0-190 rpm | |

| theoretical injection volume | 238 cubic centimeters | |

| Injection pressure | 174 MPa | |

| maximum. hydraulic | 140kg/cm | |

| Actual injection volume (PS): | 225g(ps)/8oz | |

| Screw stroke: | 190mm | |

| clamping part | ||

| Blow clamping force: | 80KN | |

| Clamping tonnage: | 400 knots | |

| Wheel diameter: | 800mm | |

| maximum. Bottle height: | ISB:145/IB:140 | |

| Turn on vertical mode strokes: | 430mm | |

| others | ||

| maximum. Pump pressure: | 16 MPa | |

| Oil: | 18.5 kW | |

| electricity: | 12.2 kW | |

| tank: | 400 liters | |

| Dimensions (L*W*H): | 3.8m*1.45m*3.0m | |

| weight: | 5000 kg | |

If you are interested in our products

Click here to leave us a message to send an inquiry >>>

we have someone tell you solution products

With the increasing demand for high-quality and elegant packaging in the field of food, beverages, and cosmetics, the plastic containers produced by the old-fashioned extrusion blowing machine can no longer meet the needs of customers. The one-step injection stretch blow molding machine, from raw materials to products, is processed in one step. The whole process includes preform injection, stretch blowing, and demoulding. No leftover material, no runner material, but perfect neck, bottom, lines, higher transparency and higher rigidity. Stretch blow molding products have thinner walls and save material.

One-step injection stretch blow molding machine can complete high-speed molding without preform reheating. Utilizes heat from preform injection to stretching and blow molding, saving energy by unnecessary reheating and reducing preform cooling time.

The one-step injection stretch blow molding machine optimizes the working structure, eliminates the unfavorable factors of molding, saves complicated procedures, ensures more reliable molding, and improves the scrap rate.

The one-step injection stretch blow molding machine reduces transportation costs and avoids secondary pollution, especially suitable for food and pharmaceutical companies. For example, to transport 19 grams of 500ML bottles, if a 1 cubic meter suitcase is used, 1024 bottles can be loaded, or 9280 preforms, but if raw materials are used, 56421 bottles can be produced. The material logistics cost can be reduced by 98.2% compared with the transfer bottle; compared with the transfer preform cost, the cost can be reduced by 83.6%.

Comparison of one-step and two-step methods:

| forming | process | structure | Human/Energy/Space | product quality |

| step | From preform to product | a machine | small | Unaffected by moisture, less contamination; various shapes |

| two steps | Injection and blow molding are two separate processes |

1. Injection molding machine 2. Preform transfer machine 3. Heating stretching demoulding machine |

more | Susceptible to moisture, contamination; single shape |

The advantages of JASU one-step injection stretch blow molding machine model ISB800-3/ISB800A-3 are as follows:

1. Wheel rotation is driven by servo motor, not hydraulic drive.

2. Fully automatic control system, easy to operate.

3. The temperature of barrel and hot runner is precisely controlled by PIT.

4. Save more cost than traditional machines.

5. Compact structure; less space required.

6. Injection:

Hot runner and temperature control device are standard configurations. Only change the mold to make a new product;

Stretch blow:

Hydraulic mold clamping, core inserting, stretch blowing and bottom forming are standard configurations;

product release:

Comes with standard injectors.

Guangzhou Jiasu Machinery Co., Ltd. has been researching, designing and manufacturing bottle blowing machines since 1989. Professional manufacture of one-step injection blow molding machines and injection stretch blow molding machines. Our solutions for plastic containers with high quality, high precision, low cost and low energy consumption have attracted the attention of the market.

More than 100 employees and more than 30 professional technicians are dedicated to JASU® brand series machines, and our R&D department is dedicated to continuously developing new bottle blowing technologies. We have set up 30 representative offices and a 24-hour maintenance service network throughout the country.

JASU® has established a high reputation among domestic and foreign customers, especially overseas customers in Southeast Asia, the Middle East, Africa, Europe, and South America. By the end of 2014, exports accounted for 60% of annual sales.

Located in the Pearl River Delta region, close to ship ports and air transportation services, especially close to Hong Kong Airport, we have the competitive advantage of a fast delivery system and a centralized supply chain center. We sincerely invite trading partners and import buyers to visit our showroom and workshop to discuss possible cooperation.

Q1: Are all your products made by yourself or buy others compressed?

A1: We have an independent technical team that focuses on manufacturing machines; all products are manufactured by our technical team.

Q2: What is the capacity of your factory?

A2: Regarding the blow molding machine, we can produce 15 machines per month

Q3: Do you have technical support for your products?

A3: We have long-term cooperation with Germany, and we have many cooperations with many advanced manufacturing companies in the world.

Q4: Do you have other services for your products?

A4: We have extensive experience in formulating complete "turnkey" projects and specifications for our customers. We also have a fixed service system

Q5: How do you quote for customers?

A5: The price depends on the quality and performance, but customers should satisfy us first

Welcome to visit our company. For more information, please feel free to contact us.

If you are interested in our products

Click here to leave us a message to send an inquiry >>>

we have someone tell you solution products

-

Professional Manufacturer Nissei ASB Machinery Plastic Injection Stretch Blow Molding Cosmetic Bottle Mold

-

Factory Price High Quality SJ-A50 Single/Double Wrap Film Blowing Machine

-

PP FILM BLOWING MACHINE

-

Fangyuan Custom Automatic Vacuum EPS Foam Bicycle Helmet Liner Manufacturing Foam Plastic Molding Machine

-

Medicine Bottle Blow Molding Machine Small HDPE pehd PP ABS PS Plastic Automatic Cheap Low Price Stretch Extrusion

-

plastic vacuum machine making toy ball doll pvc vinyl toy football machine

-

ABS Furniture Plastic Blow Molding Machine Price

-

USB Interface Vertical Injection Molding Machine Price Favorable

-

Factory Price Semi Automatic 4 Cavity PET Plastic Bottle Blow Molding Machine Plastic Bottled Water Production Line

-

ABC three-layer PE co-extrusion blown film machine

Other Products

-

$10000.00 / unit

$10000.00 / unit -

$10000.00 / set

$10000.00 / set -

$10000.00 / unit

$10000.00 / unit -

$10000.00 / set

$10000.00 / set -

$60000.00 / set

$60000.00 / set -

$10000.00 / unit

$10000.00 / unit -

$10000.00 / unit

$10000.00 / unit -

$20000.00 / set

$20000.00 / set -

$10000.00 / unit

$10000.00 / unit