Factory Price Semi Automatic 4 Cavity PET Plastic Bottle Blow Molding Machine Plastic Bottled Water Production Line

-

Supplier: Zhangjiagang Crown Machinery Co.,ltd -

Region: Jiangsu, China -

Contact: Mr Huang Zhong -

Price: $800.00 /set -

Min. Order: 1 set

Product details

| Clamping force: | 160mm | Voltage: | 220V/380V (or customized) |

| High pressure air compressor: | 1.2 cubic meters/30KG | Electric brand: | Mitsubishi Schneider Airtac |

| Mechanical test report: | if | Applicable industries: | Hotels, clothing stores, building supplies stores, manufacturing plants, machinery repair shops, food and beverage factories, farms, restaurants, home use, retail, food stores, print shops, construction, energy and mining, food and beverage stores, advertising agencies |

| Cavity: | 2 cavity | Health status: | new |

| Year: | 2019 | cylinder: | Festo/Germany |

| Marketing Type: | New Products 2020 | valve: | Festo/Germany |

| Type of machine: | Semi-automatic blow molding machine | Warranty: | 1 year |

| Local service location: | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya , Argentina, South Korea, Chile, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan | Certification: | OS/CE |

| Hollow part volume: | 350*380*210 | Video shipment inspection: | if |

| Origin: | Jiangsu, China | Showroom location: | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile , Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Japan, Malaysia, Australia |

| Supply capacity: | 5 sets per month | payment terms: | L/C, T/T |

| Applicable bottle: | 0.1L-0.5L | application: | bottle |

| brand: | Crown Machinery | Core components: | PLC, motor |

| Core component warranty: | 1 year | strength: | 17.5KW |

| Main selling points: | run smoothly | Package preview: | |

| After-sales service provided: | Free spare parts, online support, on-site installation, commissioning and training, on-site maintenance and repair services, video technical support | human Resources: | Need 2 workers to operate |

| weight: | 500KG | Plastic processing: | PVC,PET,PP,PC,FRPP/PVC,HDPE,HDPE/PP,ABS/PP |

| After warranty service: | Video technical support, on-site maintenance and repair services | automation: | semi-automatic |

| Programmable Controllers: | Delta/Taiwan | Packaging Details: | Shipping wooden box |

| Dimensions (L*W*H): | 1650*650*1700 | port: | Shanghai Port |

| product name: | Semi-automatic Plastic Blow Molding Machine | Blow molding type: | injection blow molding |

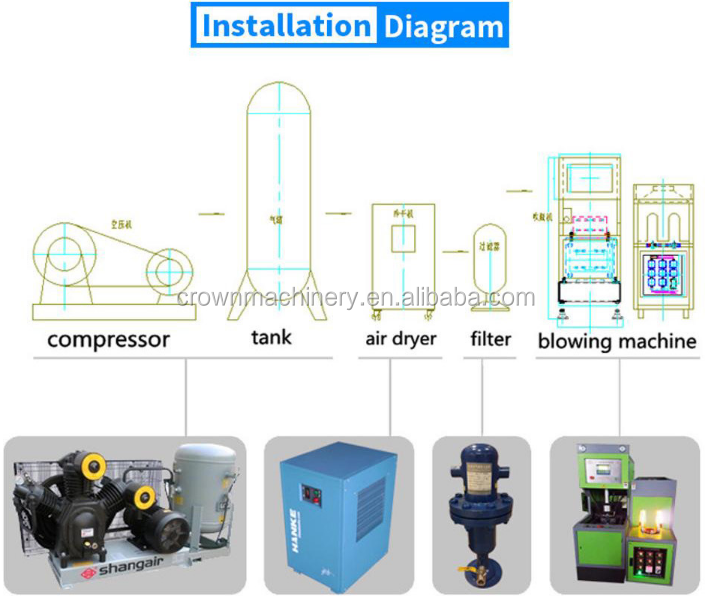

Semi-automatic blow molding machine

Product Description

GY-8Y semi-automatic bottle blowing machine is suitable for producing PET plastic containers and bottles of 10-2000ml. Widely used in the production of carbonated bottles, mineral water bottles, carbonated beverage bottles, pesticide bottles, oil bottles, cosmetics, jars, etc.

●Double-crank mold adjustment, heavy-duty mold clamping, stable and fast, infrared oven is used to heat the billet, and the billet is heated evenly when rotating.

● The air system is divided into two parts, the pneumatic action part and the bottle blowing part, to meet different action and bottle blowing requirements. It can provide sufficient and stable high pressure for blowing large special-shaped bottles.

● The machine is also equipped with a muffler and an oil injection system to lubricate the mechanical parts of the machine.

● The machine can be operated in stepper mode and semi-automatic mode.

● The machine has low investment, convenient and safe operation.

●Double-crank mold adjustment, heavy-duty mold clamping, stable and fast, infrared oven is used to heat the billet, and the billet is heated evenly when rotating.

● The air system is divided into two parts, the pneumatic action part and the bottle blowing part, to meet different action and bottle blowing requirements. It can provide sufficient and stable high pressure for blowing large special-shaped bottles.

● The machine is also equipped with a muffler and an oil injection system to lubricate the mechanical parts of the machine.

● The machine can be operated in stepper mode and semi-automatic mode.

● The machine has low investment, convenient and safe operation.

Main features of bottle blowing machine:

1. PLC control and stable production. The touch screen operates the machine, which is easy to operate.

2. One worker is enough, the operation is simple and no special training is required.

3. Low cost, less investment and energy saving.

2. One worker is enough, the operation is simple and no special training is required.

3. Low cost, less investment and energy saving.

4. Almost no maintenance cost.

Model | GD-880 | GD-880-II | GD-3L |

Bottle material | pet | pet | pet |

Bottle volume(L) | 0.1-2 | 0.1-1.5 | 2-5 |

Capacity (pca/h) | 800-1000 | 1400-1800 | 300-650 |

height (mm) | ≤300 | ≤280 | ≤350 |

Execution inner diameter | ≥∮12 | ≥∮12 | ≥∮16 |

Maximum mold diameter (mm) | 350*380 | 350*380 | 400*460 |

Maximum mold thickness (mm) | 210 | 210 | 260 |

Clamping force (kn) | 45 | 45 | 65 |

Mold opening stroke(mm) | 160 | 160 | 220 |

host (mm) | 1600*620*1610 | 1600*600*1610 | 1750*670*1860 |

Host weight(kg) | 500 | 500 | 600 |

Heater (mm) | 1870*630*1450 | 1870*630*1450 | 1870*630*1450 |

Heater weight(kg) | 250 | 250 | 250 |

Power(kw) | 17.5 | 24.8 | 17.5 |

detailed image

VIEW MORE

You may like

-

Professional Manufacturer Nissei ASB Machinery Plastic Injection Stretch Blow Molding Cosmetic Bottle Mold

-

Factory Price High Quality SJ-A50 Single/Double Wrap Film Blowing Machine

-

Chinese supplier of full automatic tennis ball making machine

-

PP FILM BLOWING MACHINE

-

Fangyuan Custom Automatic Vacuum EPS Foam Bicycle Helmet Liner Manufacturing Foam Plastic Molding Machine

-

Medicine Bottle Blow Molding Machine Small HDPE pehd PP ABS PS Plastic Automatic Cheap Low Price Stretch Extrusion

-

plastic vacuum machine making toy ball doll pvc vinyl toy football machine

-

ABS Furniture Plastic Blow Molding Machine Price

-

USB Interface Vertical Injection Molding Machine Price Favorable

-

ABC three-layer PE co-extrusion blown film machine

Related Search

good price semi automatic paper box machine

full automatic plastic blow molding machine suppliers

semi fully automatic blow molding machine

plastic blowing molding machine guangzhou

semi blow molding machine

economical pet blow molding machine suppliers

pneumatic full automatic blow molding machine

bottle blow molding machine plastic pipe

two head plastic blow molding machine

pet blow molding machine