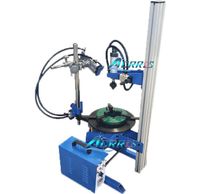

Welding Positioner

-

Supplier: Chengdu Hanyan Technology Co., Ltd. -

Region: Sichuan, China -

Contact: Mr peter qi -

Price: $3000.00 /set -

Min. Order: 1 set

| Weight (kg): | 400 kg | Video outbound inspection: | if |

| Showroom location: | Egypt, Turkey, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Thailand | Health status: | new |

| Applicable industries: | manufacturing plant | Core components: | PLC, bearings, gearboxes, motors, gears |

| Core component warranty: | 1 year | current: | 9.6A |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | usage: | welding |

| Certification: | CE/ISO9001 | brand: | Hanyan Technology |

| Marketing Type: | normal product | Main selling points: | automatic |

| Supply capacity: | 10 groups per week | type: | Welding positioner |

| port: | Shanghai | Voltage: | Three-phase 380V |

| color: | blue | After-sales service provided: | Engineers available to repair machinery overseas |

| aspect: | 2300*800*1500 mm | weight: | 2.78 tons |

| Packaging Details: | Wooden box; 2300x800x1600 mm; 700 kg. | Mechanical test report: | if |

| Warranty: | 1 year | Origin: | Sichuan Province, China |

1.1.application:

It is mainly used for welding precision workpieces such as instruments, bellows, medical equipment and electronic components.

1.2.Element:

It consists of a rotating spindle box, a tailstock, a bed, a three-dimensional adjustment mechanism, a pneumatic lifting mechanism and a PLC control system.

1.2.1.Lathe bed:With guide rail, the distance between headstock and tailstock is adjustable.

1.2.2.Rotating headstock:Driven by a DC geared motor, it has a stepless speed regulation function and a welding current detection switch.

1.2.3.Tailstock:With handwheel for transferring movement to the center of the lathe.

1.2.4.3-D adjustment mechanism:Adjust the torch position accurately.

1.2.5.Pneumatic lift:Automatically raises the torch.

1.2.6.Travel mechanism:Automatic longitudinal seam welding and moving trolley.

1.2.7.Control System:Advanced PLC control system, humanized operation interface, high degree of automation, stable and reliable performance.

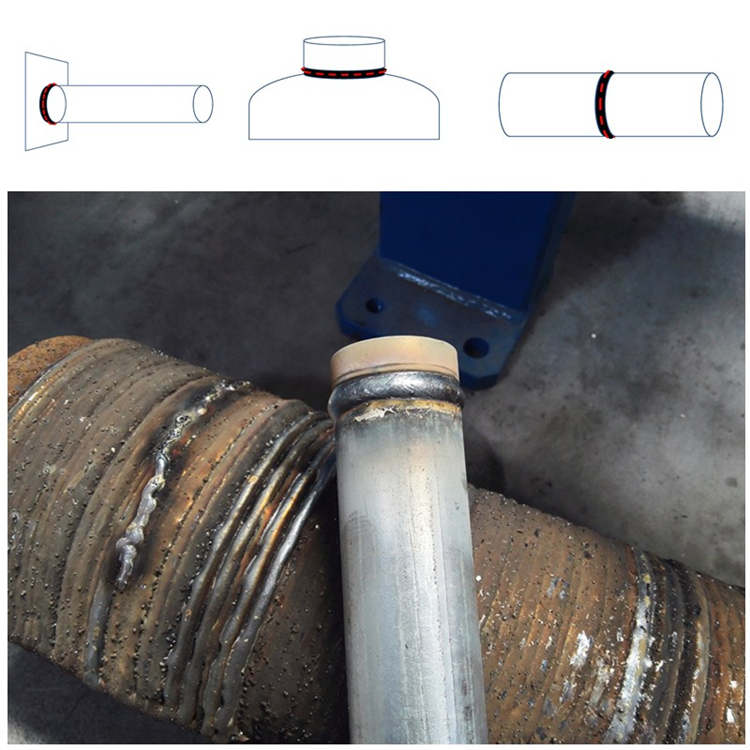

1.3.Welding process:

1.3.1.Welding method:The torch is fixed and the workpiece rotates. Automatic welding.

1.4. universality:

1.4.1. Available forTIG/MIG/MAG/PAW/SAWwelding applications.

1.4.2. Can be used for weldingPipe/Pipe/Flange/Coneetc.

1.4.3. Compatible withOscillators, seam trackers, wire feedersand other functional components.

| thing | unit | HTC-3C | HF-300W | HF-300WS | HF-300L | HF-300LY |

| maximum. Work piece length | mm | 500 | 1200 | - | ||

| maximum. Workpiece weight | Kilogram | 30 | 50 | 250 | ||

| maximum. Workpiece diameter | mm | 350 | 550 | 600 | ||

| Chuck working diameter | mm | 10 - 120 | 10 - 200 | - | ||

| Hole diameter | mm | 30 | 50 | - | ||

| Torch stroke (pneumatic) | mm | 100 | 150 | |||

| Tailstock travel (pneumatic) | mm | - | 150 | - | - | |

| Headstock speed | Rotating speed | 1 - 10 | 0.6 - 6 | |||

| Headstock Angle | ° | 0°, 30°, 45°, 60°, 90° | - | |||

| torch adjustment | mm | X: ± 30 mm Y: ± 30 mm Z: ± 30 mm | ||||

| maximum. Welding current | A | 500 | ||||

| power input | V | AC 1 phase 220V (±10%) 50Hz | ||||

| weight | Kilogram | 310 | 380 | 400 | 300 | 350 |

| pack | cubic meter (cubic meter) | 1.45 | 2.39 | 2.39 | 1.08 | 1.37 |

In user factory:

1. Pre-sales: on-site technical solutions and quotations.

2. After-sales: installation, commissioning, training.

In our factory:

-

Pipe work piece rotating machine turntable 30kg mini welding positioner for sale

-

220V 30kg 100kg 300kg China Pipe Flip Positioner Welding Turntable Sales

-

Control tube welding positioner with foot switch 50kg per tube

-

10kg automatic welding positioner welding turntable for pipe rotation welding

-

China Wuxi YC Automatic Welding Positioner with Automatic Rotary Welding Table

-

Three-jaw shaft tube welding positioner

-

Small welding positioner/electric rotary table for MIG/50KG welding table with WP200 manual chuck/rotator wdbwj-0.5

-

rotary welding table 10 kg rotary welding positioner with 65 mm chuck and foot pedal

-

Welding turntable/rotary table/welding positioner can stop by itself Load capacity 300KG with 400mm welding chuck

-

The automatic welding positioner adopts special anti-electromagnetic design

Other Products

-

$5000.00 / set

$5000.00 / set -

$5000.00 / set

$5000.00 / set