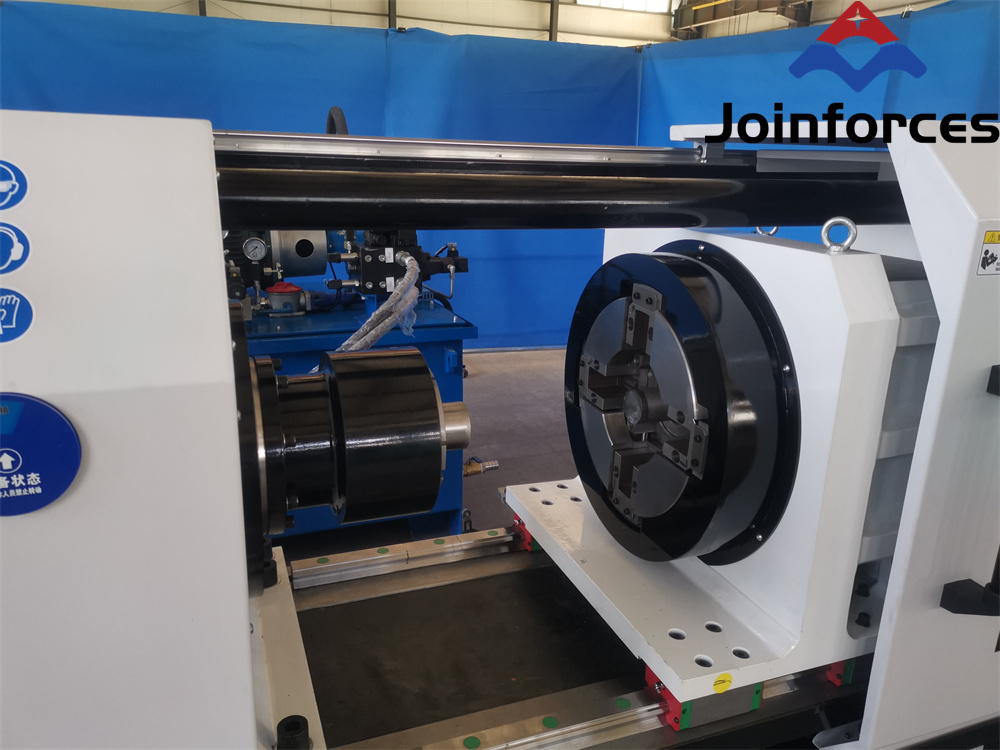

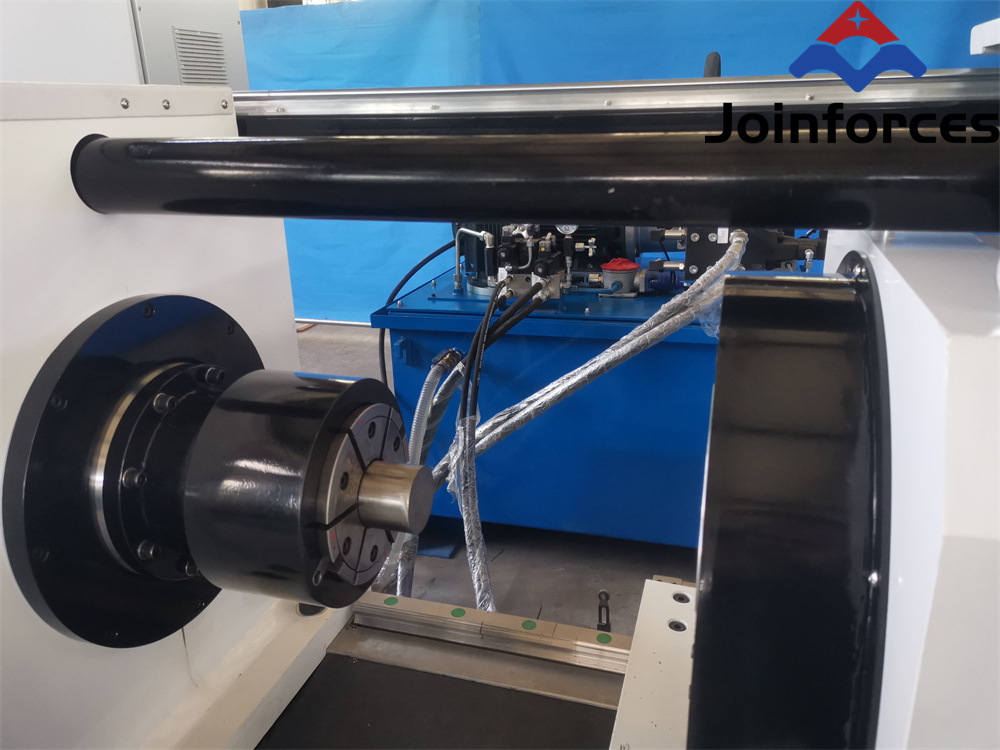

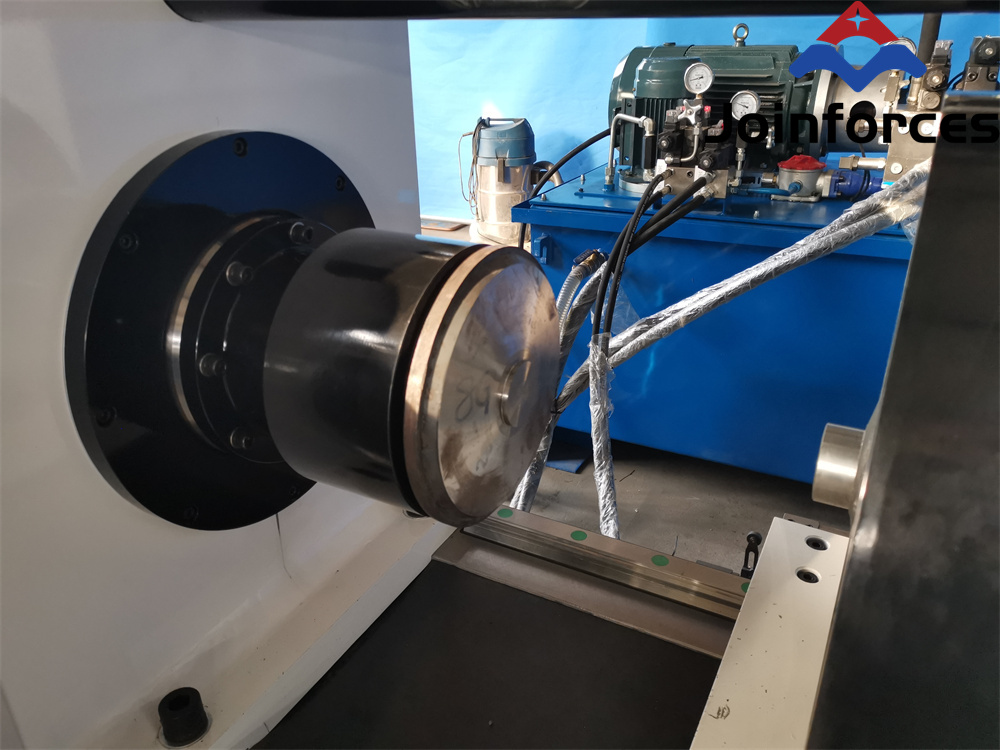

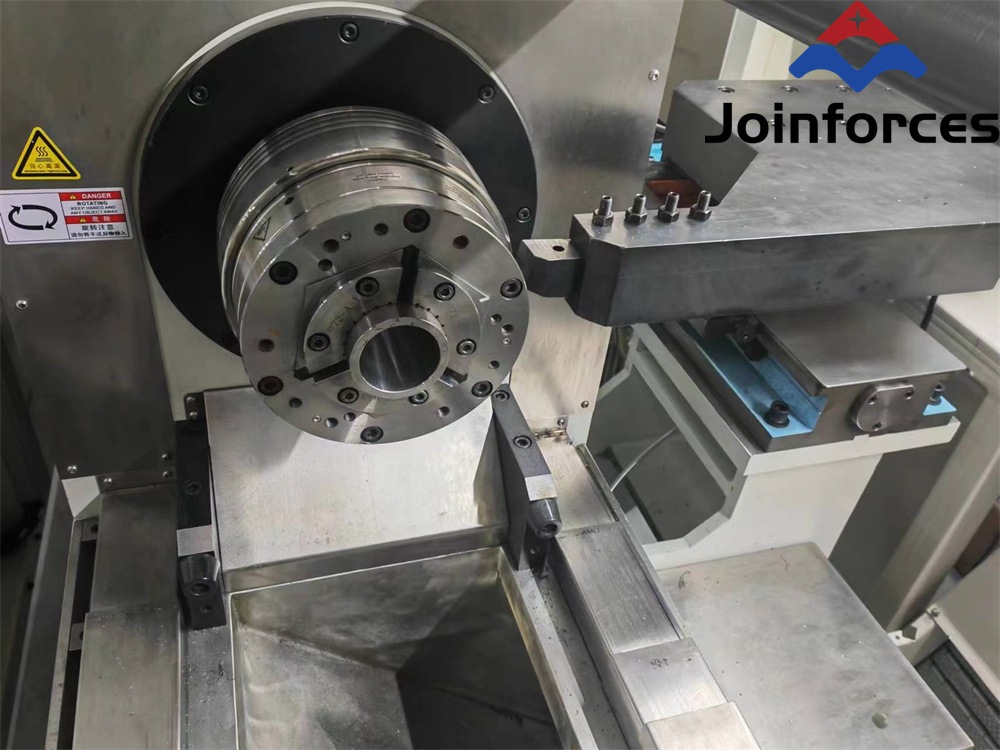

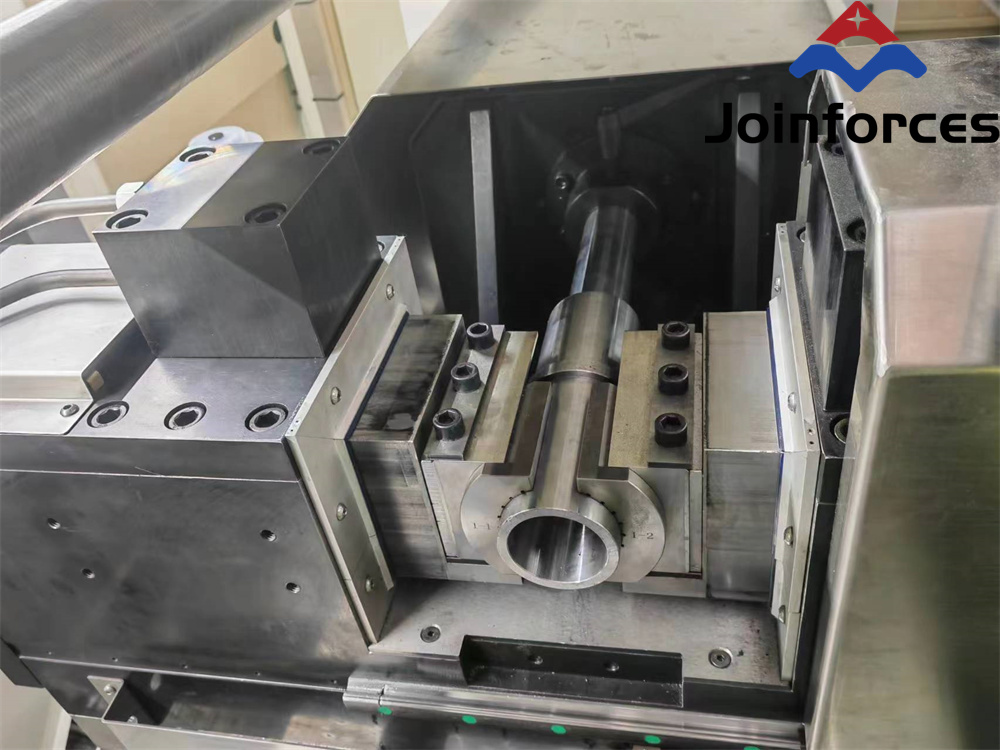

Mining drill pipe friction welding machine Rotary friction welding machine

-

Supplier: Zhonghe Machinery Technology(Dalian) Co., Ltd. -

Region: Liaoning, China -

Contact: Ms Anna Yang -

Price: $108000.00 / 1 - 4 sets

$106000.00 / >=5 sets -

Min. Order: 1 set

Product details

| Warranty: | 1 year | Main selling points: | Low maintenance costs and high productivity |

| Clamping length of moving fixture: | 80-450mm or unlimited | Video outbound inspection: | if |

| Weld diameter: | 3-150 mm | Showroom location: | not any |

| Rated Capacity: | 100% | Core components: | PLC, engine, bearing, motor, gear |

| port: | Dalian | Mechanical test report: | if |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Maximum upsetting force: | 25-1200KN |

| Applicable industries: | Energy & Mining, Oilfield Parts, Military, Agriculture & Trucking, Aircraft/Aerospace, Bimetals & Specialty | aspect: | Different models and different sizes |

| brand: | united forces | Origin: | Liaoning, China |

| type: | friction welding machine | Marketing Type: | normal product |

| Voltage: | 380V | After Warranty Service: | Video technical support, online support, |

| Health status: | new | usage: | Metal welding, friction welding machine |

| Weight (kg): | 13000 kg | Rotating speed: | rely on |

| Packaging Details: | Export standard packaging, wooden box packaging film. Can also be requested by customers. | Swivel fixture clamping length: | 20-300mm |

| Core component warranty: | 1 year | aspect: | custom made |

product description

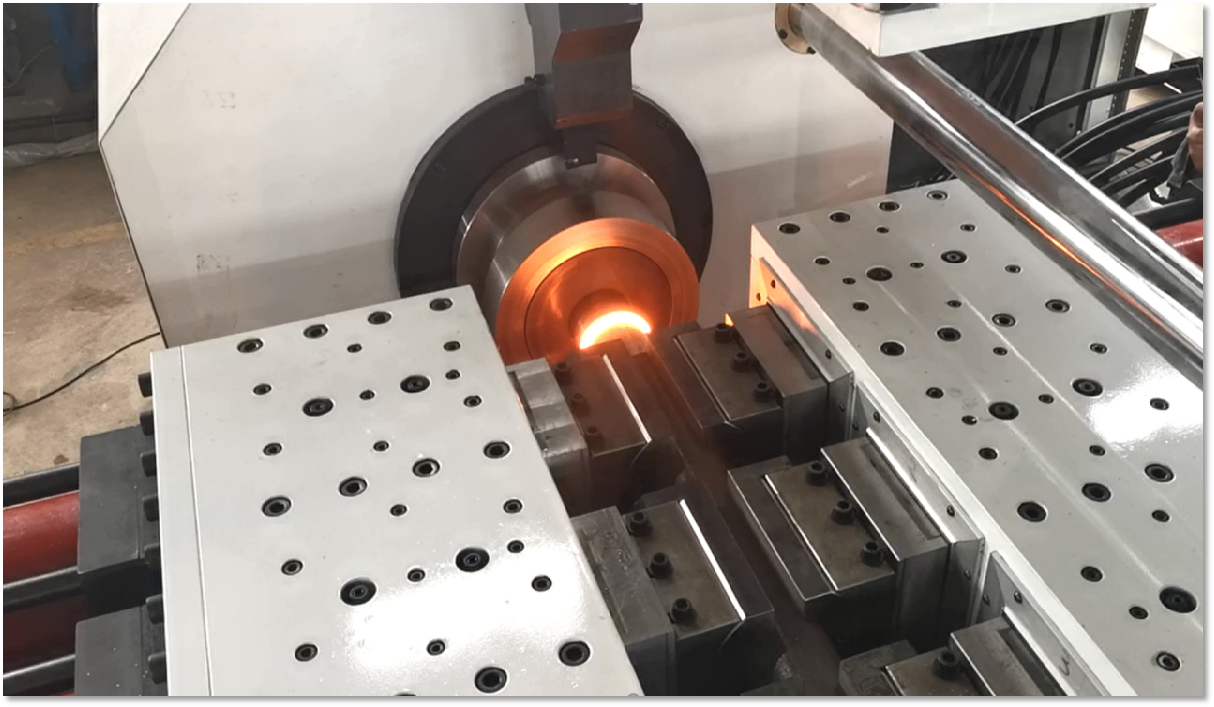

What is Friction Welding?

Friction welding is a solid-state joining technique that welds workpieces by generating heat through mechanical friction. The heat generated between the surfaces is exploited through a combination of mechanically induced frictional motion and applied loads. by "United"

friction welder, resulting joints are of forged quality. Under normal conditions, the mating surfaces will not melt.The process does not require filler metal, flux and shielding gas.

advantage

1. Easily join dissimilar metals. This means being able to use more expensive corrosion resistant materials where required, and

Use less resistant but strong enough material where it is not required on the same part.

Use less resistant but strong enough material where it is not required on the same part.

2. The welding process consumes its own base metal to achieve metallurgical bonding, resulting in friction welding joints

Forged quality strength.

Forged quality strength.

3. The entire surface of the cross-section is composed of two metals, airtight and void-free. Friction welds are generally less costly because

There are no consumables such as filler metal flux.

There are no consumables such as filler metal flux.

product specification

Model | maximum. Upsetting force (KN) | Moving Fixture Workpiece Length(mm) | Welding diameter (mm) | RPM(MAX.) Variable(r/min) |

ZHFW-2 | 20 | 20-140 | 5-13 | 5000 |

ZHFW-5 | 50 | 50-260 | 8-18 days | 3000 |

ZHFW-12 | 120 | 150-700 | 14-30 days | 1500 |

ZHFW-20 | 200 | 150-1020 | 14-36 | 1500 |

ZHFW-30 | 300 | 314-1600 | 20-45 | 1200 |

ZHFW-40 | 400 | 500-2400 | 25-55 | 1100 |

ZHFW-63 | 630 | 960-3400 | 35-64 | 1000 |

ZHFW-80 | 800 | 1300-5000 | 40-75 | 950 |

ZHFW-100 | 1000 | 1600-6000 | 45-86 | 890 |

ZHFW-125 | 1250 | 2000-7800 | 50-100 | 600 |

ZHFW-160 | 1600 | 4300-8792 | 89-160 | Chapter 580 |

ZHFW-200 | 2000 | 5100-12500 | 102-189 | 500 |

ZHFW-250 | 2500 | 3850-15500 | 70-140 | 500 |

ZHFW-320 | 3200 | 6400-20000 | 90-160 | 380 |

ZHFW-400 | 4000 | 8000-25000 | 100-180 | 350 |

ZHFW-500 | 5000 | 8000-31400 | 100-200 | 320 |

ZHFW-700 | 7000 | 8000-44000 | 100-240 | 320 |

application

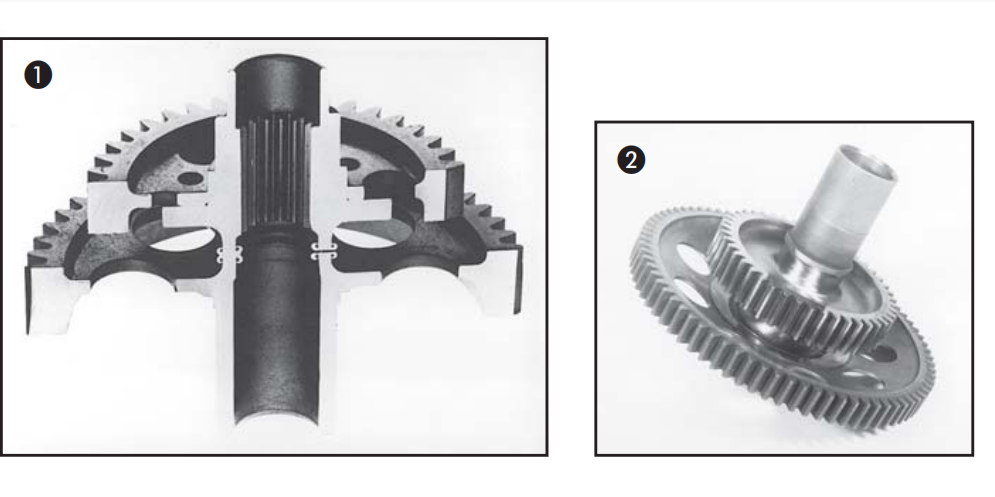

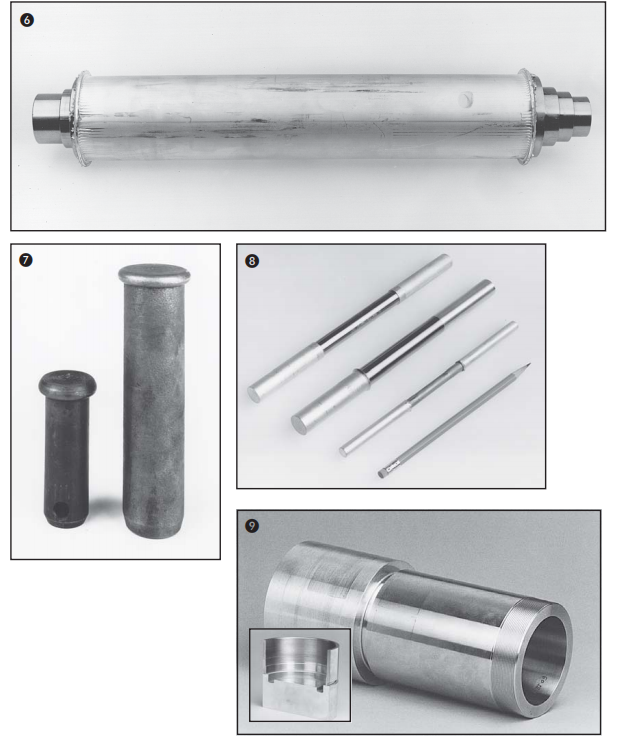

Aircraft/Aerospace

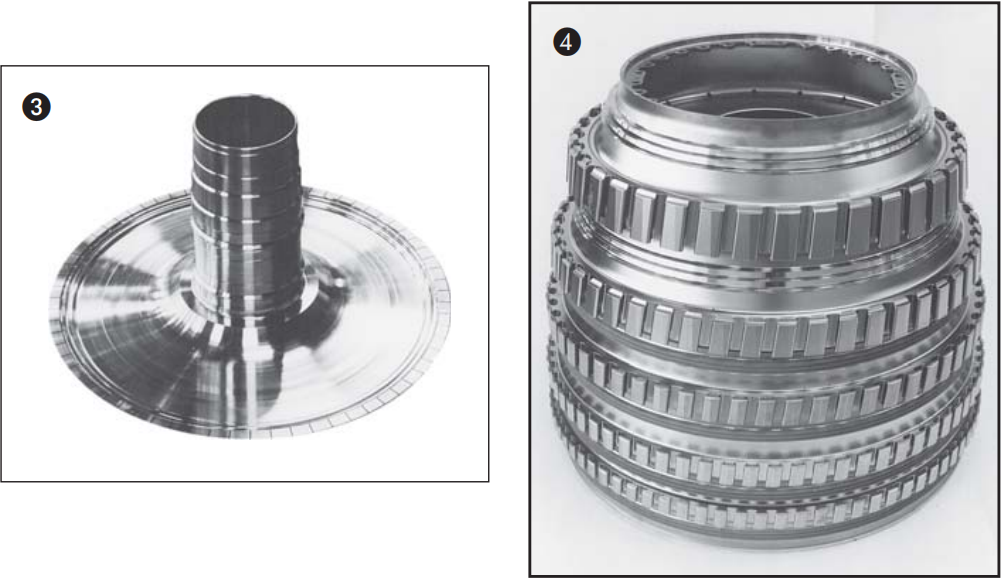

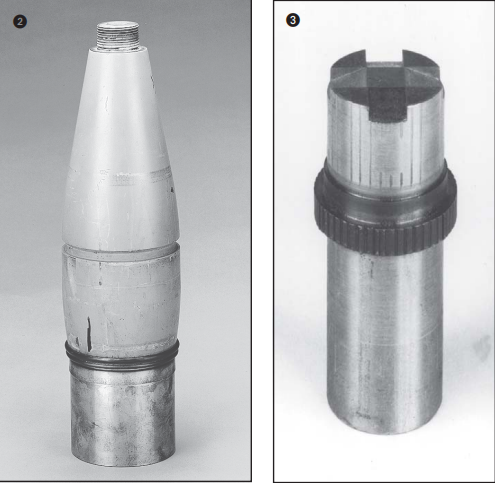

1. Cluster gear section2. Cluster gear

Aircraft/Aerospace

3. Inconel 718 tube to rotor assembly 4. low compression titanium

Aircraft/Aerospace

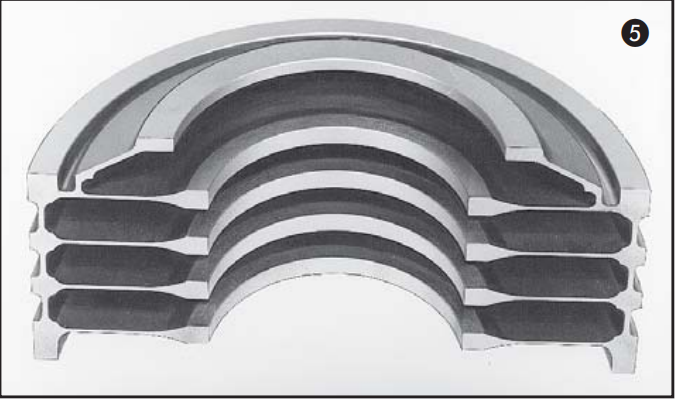

5. Welded jet engine compressor rotor

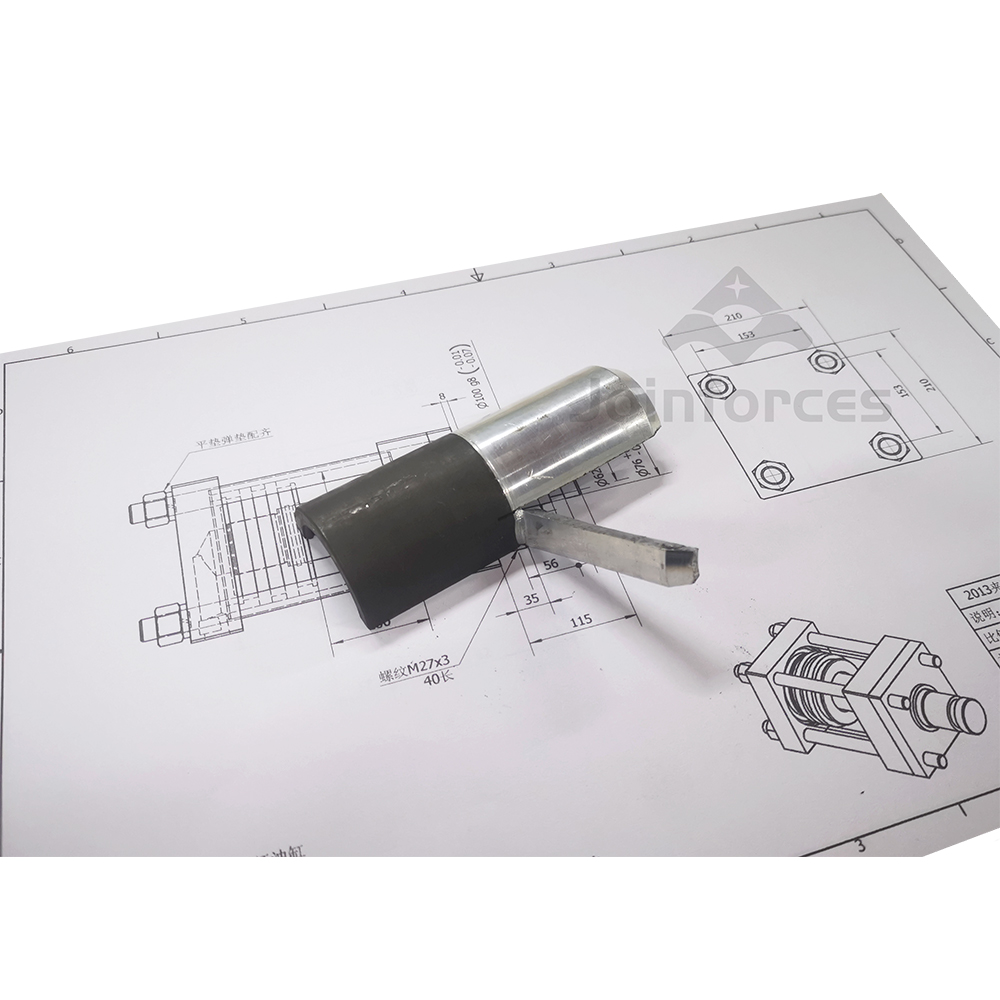

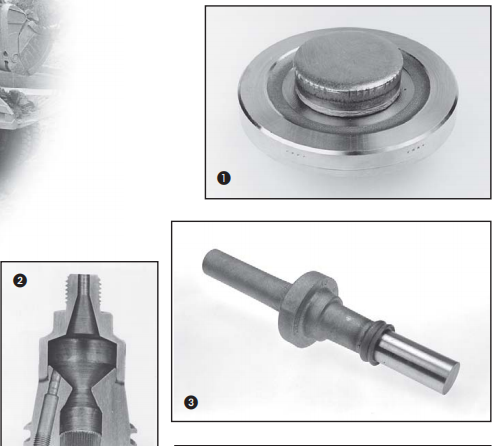

oilfield works

1. Butterfly valve. Forged stainless steel extension welded to investment pattern

Cast stainless steel butterfly valve

Cast stainless steel butterfly valve

oilfield works

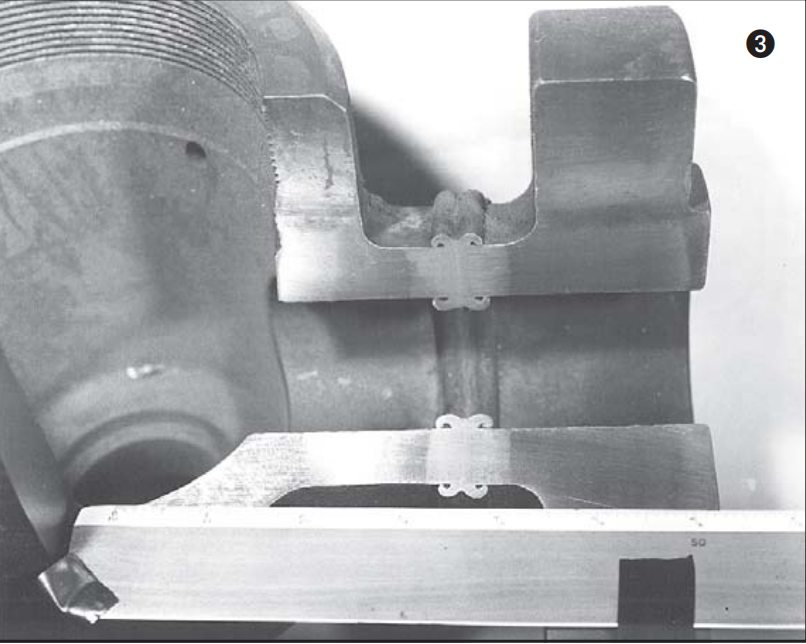

2. High pressure valve body. Forged flange welded to forged body

oilfield works

3. High pressure valve body weld seam section.

oilfield works

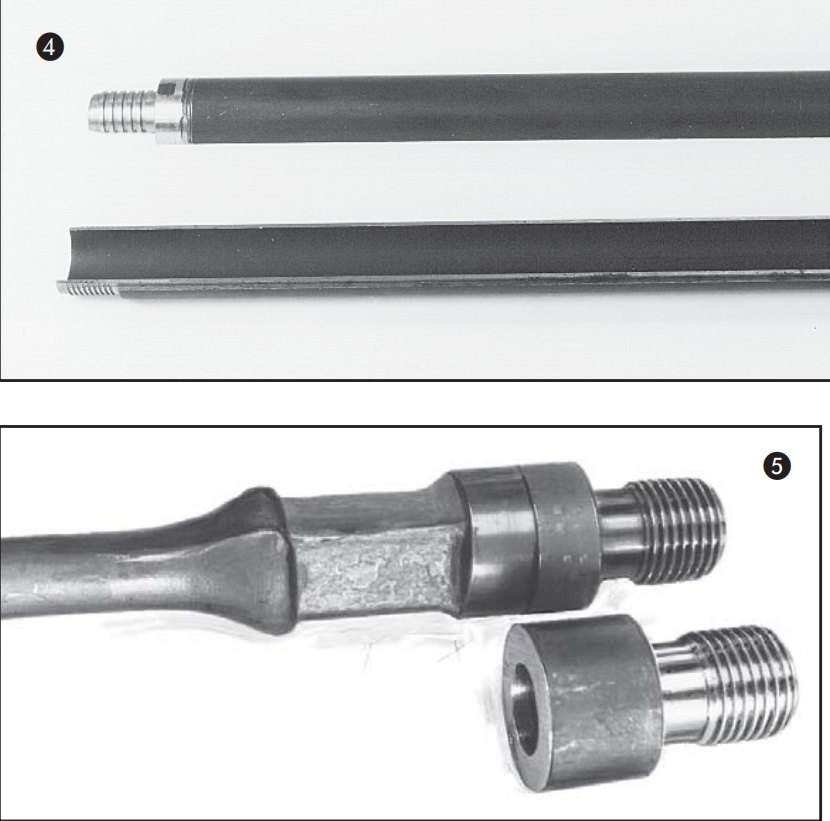

4. Geological core drilling rig. SAE4140 end blanks welded to SAE4140 tubing.5. Sucker rod. Threaded end fittings for connection to forged sucker rods.

oilfield works

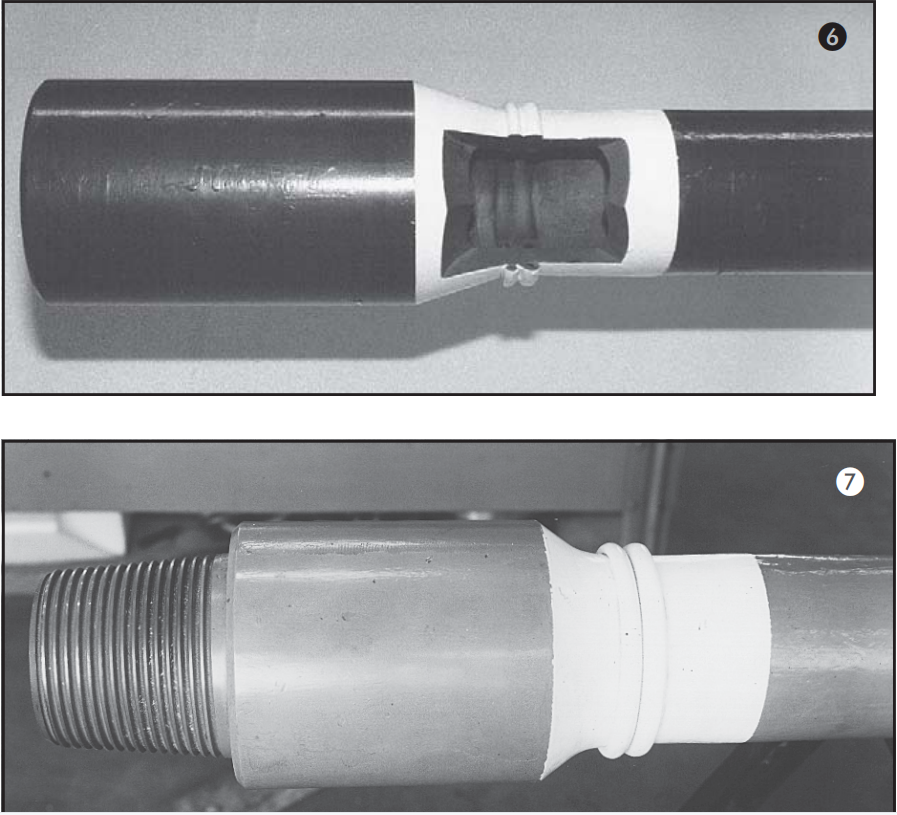

6. Oil well drill pipe. A close-up of the drill pipe joint of the drill pipe weld. female end.7. Oil well drill pipe. A close-up of the drill pipe joint of the drill pipe weld. male end.

oilfield works

8. Section of inertia welded manifold for oil wellhead.

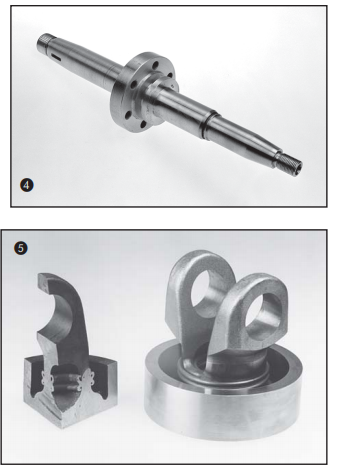

army

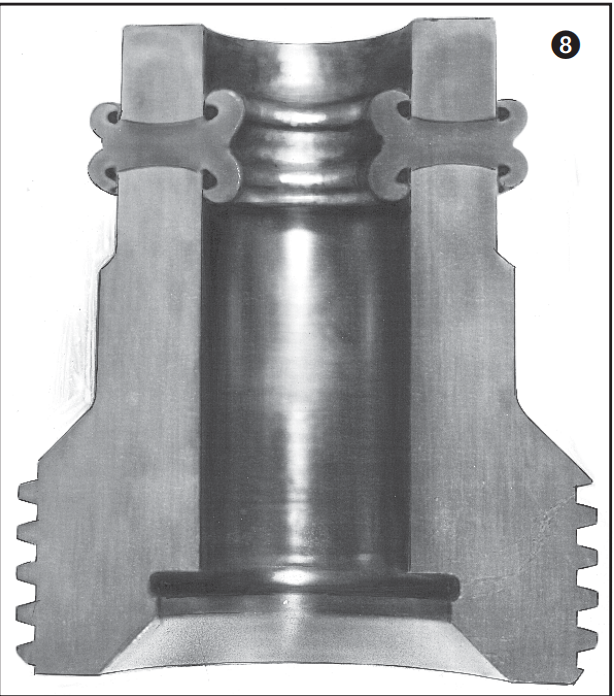

2. Mortar rounds.

3. Copper alloy strip up to 30 mm

steel body.

3. Copper alloy strip up to 30 mm

steel body.

army

5. Impact wrench extension.

army

6. The copper alloy rotating belt is radially welded on the 155mm alloy steel body and section.

7. Experimental aluminum soot paste.

7. Experimental aluminum soot paste.

Bimetallic and special applications

1. Carbon steel/stainless steel marine outboard drive shaft

2. Bimetal pump motor shaft. Stainless steel spool connected to carbon steel shaft

For corrosion resistance.

3. Inertia welded copper-aluminum tensile specimens.

2. Bimetal pump motor shaft. Stainless steel spool connected to carbon steel shaft

For corrosion resistance.

3. Inertia welded copper-aluminum tensile specimens.

Bimetallic and special applications

5. Various aluminum/copper electrical examples

Connectors and threaded titanium/copper electrode studs.

Connectors and threaded titanium/copper electrode studs.

Bimetallic and special applications

6. Aluminum/stainless steel copier fuser roller.

7. Complete the pin head using the "break" weld cycle.

8. Solid 2219 aluminum/304 stainless steel tubing.

9. Transition joints for cryogenic applications. Inconel to Aluminum

7. Complete the pin head using the "break" weld cycle.

8. Solid 2219 aluminum/304 stainless steel tubing.

9. Transition joints for cryogenic applications. Inconel to Aluminum

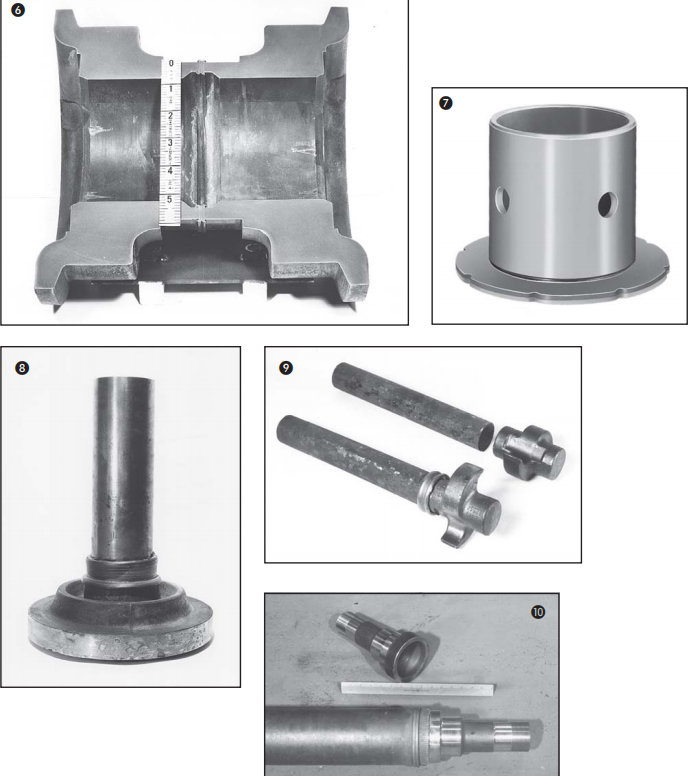

Agriculture and Freight

1. Water pump gear.

2. Inertia section

Welded diesel engine pre-combustion chamber - SAE5120.

3. Water pump - welded state

2. Inertia section

Welded diesel engine pre-combustion chamber - SAE5120.

3. Water pump - welded state

Agriculture and Freight

4. Water pump - done.

5. Diesel engine piston.

5. Diesel engine piston.

Agriculture and Freight

6. Track rollers. The forged halves are welded together to produce the roller assembly.

7. Steel back, bronze laminated thrust washer and sleeve welded together

Production of track roller bushings. Instead of expensive solid bronze castings.

8. 4" (101.6 mm) diameter bar stock welded to hub forging to produce rear

Tractor axle.

9. Truck Trailer Brake S-Cam.

10. Forged axle connection diameter is 5" (127mm), 0.5" (12.7mm)

Wall tubes for the production of trailer axles.

7. Steel back, bronze laminated thrust washer and sleeve welded together

Production of track roller bushings. Instead of expensive solid bronze castings.

8. 4" (101.6 mm) diameter bar stock welded to hub forging to produce rear

Tractor axle.

9. Truck Trailer Brake S-Cam.

10. Forged axle connection diameter is 5" (127mm), 0.5" (12.7mm)

Wall tubes for the production of trailer axles.

Agriculture and Freight

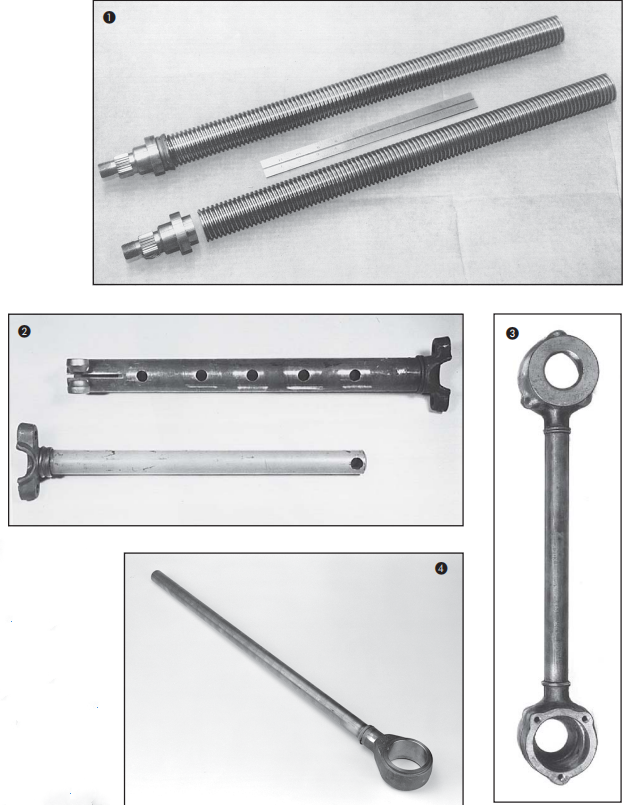

1. Lift the screw. roll

Thread stock is cut to length and welded to threaded ends.

2. Lift the connecting rod socket. Forged joints welded to tubes and bars.

3. Truck rear suspension

Connections welded on twin 150 Inertia Welders. Both ends are oriented within ±1°

other.

4. Torsion bar. forged eye

Welded to various rods

stock length.

Thread stock is cut to length and welded to threaded ends.

2. Lift the connecting rod socket. Forged joints welded to tubes and bars.

3. Truck rear suspension

Connections welded on twin 150 Inertia Welders. Both ends are oriented within ±1°

other.

4. Torsion bar. forged eye

Welded to various rods

stock length.

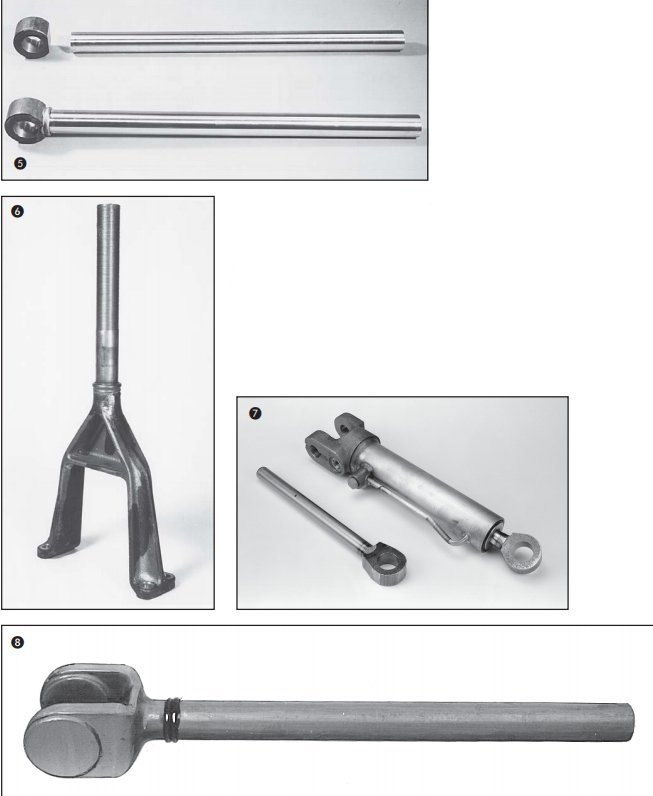

Agriculture and Freight

5. Hydraulic piston rod. Rod eyes cut from thick walls

The tubes are welded to pre-chromed rod stock.

6. Track adjustment yokes for commercial tracked vehicles.

7. Hydraulic piston rod.

8. Bars are welded to U-shaped forgings for fabrication

Large (5 in. (127 mm) diameter and larger) piston rods.

The tubes are welded to pre-chromed rod stock.

6. Track adjustment yokes for commercial tracked vehicles.

7. Hydraulic piston rod.

8. Bars are welded to U-shaped forgings for fabrication

Large (5 in. (127 mm) diameter and larger) piston rods.

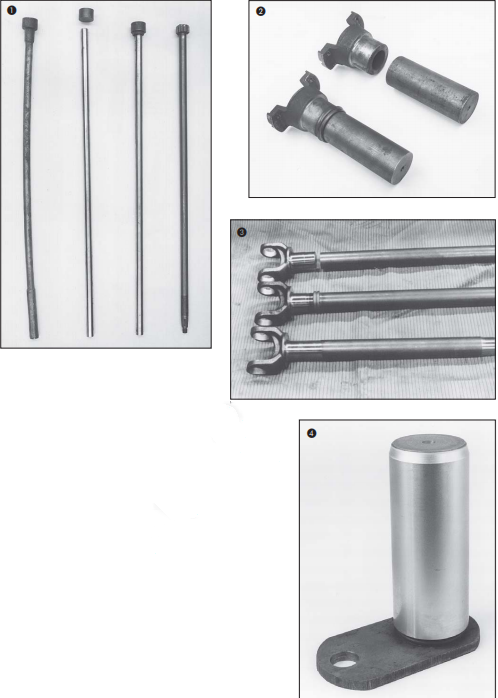

Agriculture and Freight

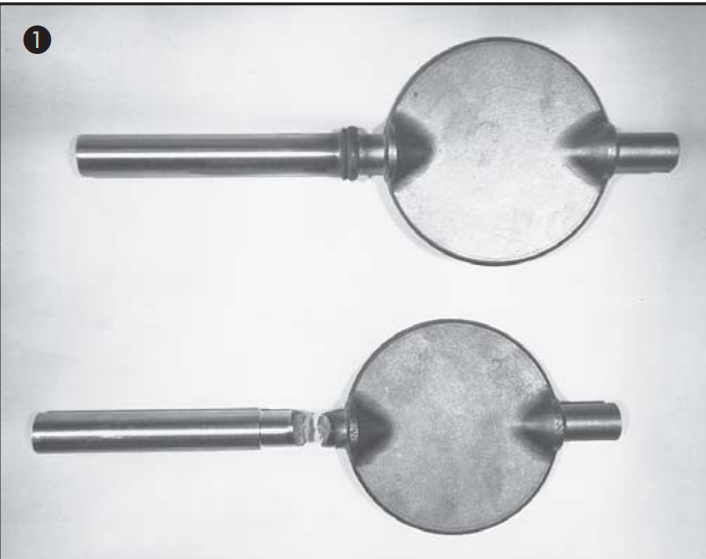

1. Motor grader power control drive shaft. An inertia weldment replaces an upset forging (left) that required five straightening operations.

2. Universal joint U-shaped clip.

3. The fork shaft of the front axle of the four-wheel drive vehicle. SAE1040 bar stock to

SAE 1040 Yoke Forgings.

2. Universal joint U-shaped clip.

3. The fork shaft of the front axle of the four-wheel drive vehicle. SAE1040 bar stock to

SAE 1040 Yoke Forgings.

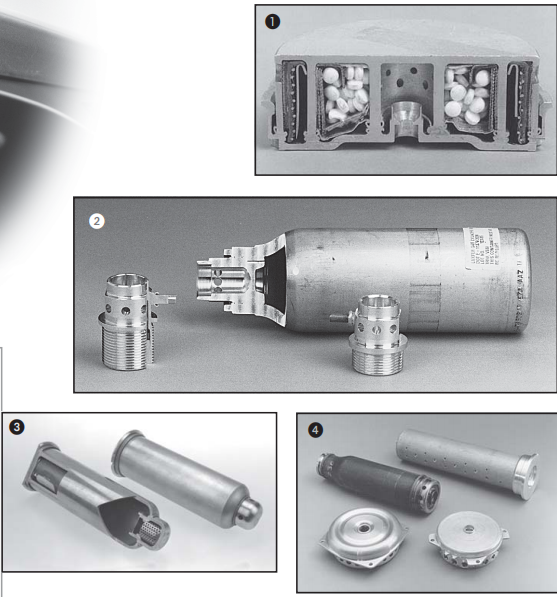

car

1. Driver side air bag inflator –

cross section.

2. Passenger side airbag.

3. Hybrid Passenger Side

Airbag inflator.

4. Driver and passenger side

Airbag inflator.

cross section.

2. Passenger side airbag.

3. Hybrid Passenger Side

Airbag inflator.

4. Driver and passenger side

Airbag inflator.

car

5. Side impact airbags

inflator.

6. Passenger side airbag

Inflators and Cross Sections

(aluminum)

inflator.

6. Passenger side airbag

Inflators and Cross Sections

(aluminum)

car

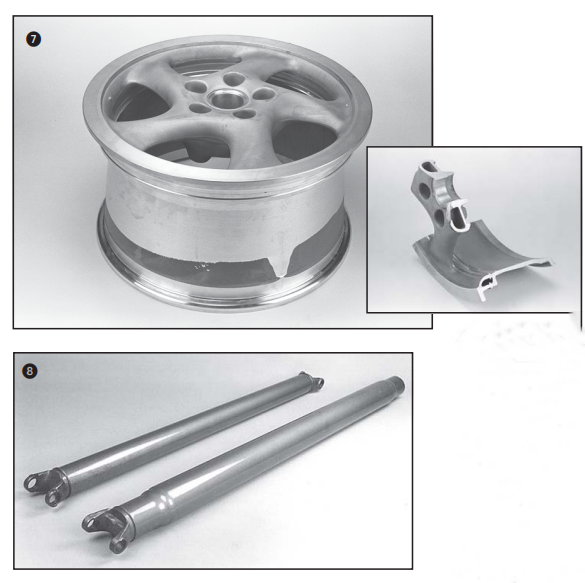

7. Aluminum rim and cross section.

8 Forgings can be welded to bar, tube, plate, etc. as shown in these drive shafts.

8 Forgings can be welded to bar, tube, plate, etc. as shown in these drive shafts.

car

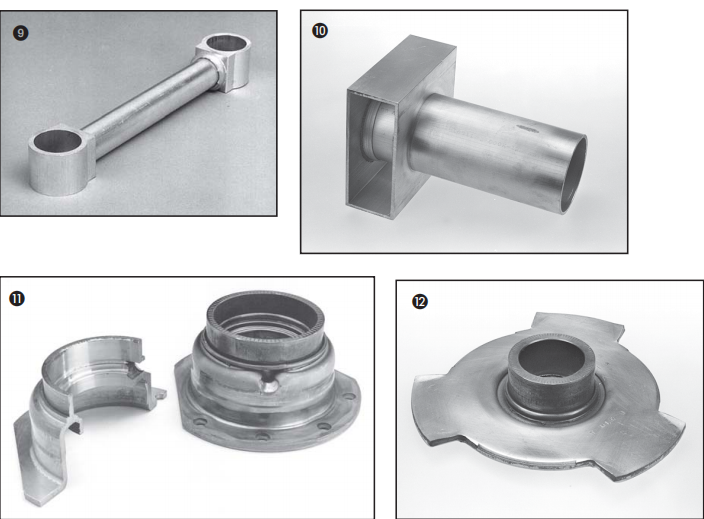

9. Experimental aluminum suspension linkage.

10. Experimental chassis components.

10. Experimental chassis components.

11. Cage—differential bearing blank cross

section (left). Transaxle bearing housing retainer (right).

12. Transmission part

section (left). Transaxle bearing housing retainer (right).

12. Transmission part

car

1. Hollow engine valve

Lightweight and Liquid Cooled

application.

2. Flange shaft.

3. Hollow automobile rear axle experiment. The tubes are welded to the hub forgings and spline blanks. Replaces solid forging to save weight.

4. Bimetal engine exhaust valve showing head and stem components, valve in welded condition, and welded valve with flash removed by shearing.

5. Automatic transmission output shaft. Stamped steel flange welded to bar

Lightweight and Liquid Cooled

application.

2. Flange shaft.

3. Hollow automobile rear axle experiment. The tubes are welded to the hub forgings and spline blanks. Replaces solid forging to save weight.

4. Bimetal engine exhaust valve showing head and stem components, valve in welded condition, and welded valve with flash removed by shearing.

5. Automatic transmission output shaft. Stamped steel flange welded to bar

car

8. Alternator bracket. Bars welded to plates replace forgings.

9. Viscous drive fan coupling. Replace forgings.

10. Starter pinion assembly. Sintered steel gears are welded to the sleeve.

11. Automotive hydraulic jacks. Made of pipe and sheet.

12. Cross section of hydraulic jack showing 2 tubular welds which are

Simultaneously fabricated on the substrate.

13. Speed selector shaft. Mild Steel Yoke Welded to SAE1045 Shaft Replacement Pin Assembly

9. Viscous drive fan coupling. Replace forgings.

10. Starter pinion assembly. Sintered steel gears are welded to the sleeve.

11. Automotive hydraulic jacks. Made of pipe and sheet.

12. Cross section of hydraulic jack showing 2 tubular welds which are

Simultaneously fabricated on the substrate.

13. Speed selector shaft. Mild Steel Yoke Welded to SAE1045 Shaft Replacement Pin Assembly

General

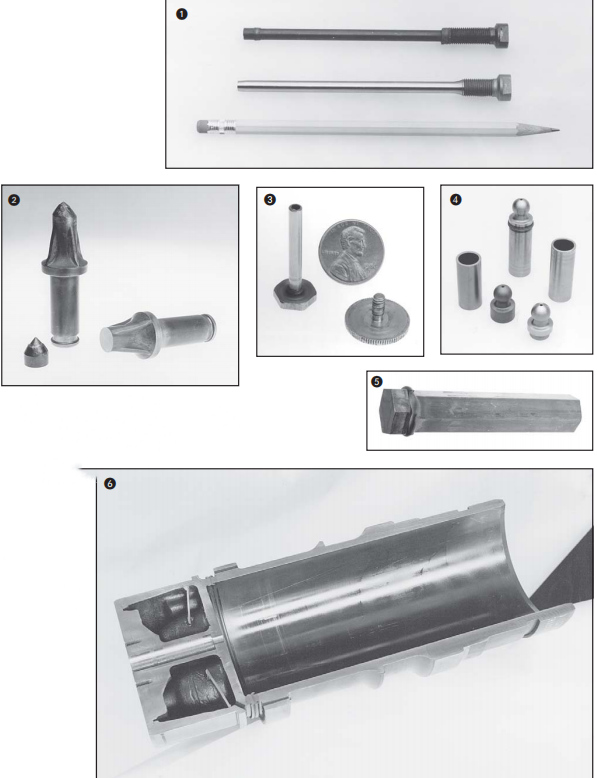

1. Tool steel to carbon steel drill bit.

2. Twist drill blanks. Welding blank made by M10 tool

Steel body and SAE4140 shank.

3. Countersink. High speed steel (M2, M42) head

Welded to mild steel (1020) shank.

4. Keyway milling cutter and T-slot milling cutter. Welding blanks are made of

AISI 6145 handle and M4 tool steel head.

2. Twist drill blanks. Welding blank made by M10 tool

Steel body and SAE4140 shank.

3. Countersink. High speed steel (M2, M42) head

Welded to mild steel (1020) shank.

4. Keyway milling cutter and T-slot milling cutter. Welding blanks are made of

AISI 6145 handle and M4 tool steel head.

General

7..375" (9.5 mm) diameter studs welded to back plate.

8. Lift the screw assembly. Acme threaded rod welded to clevis

clogged.

9. Complete the ball and install the studs.

10. Outboard motor flywheel ring gear. Forged hubs are welded to stamped and heat-treated ring gears.

11. Forged eye welded to bar.

12. The actuator arm of the sewing machine.

8. Lift the screw assembly. Acme threaded rod welded to clevis

clogged.

9. Complete the ball and install the studs.

10. Outboard motor flywheel ring gear. Forged hubs are welded to stamped and heat-treated ring gears.

11. Forged eye welded to bar.

12. The actuator arm of the sewing machine.

General

1. Composite drive

blade.

2. Mining bit.

3. Micro welding application.

blade.

2. Mining bit.

3. Micro welding application.

4. Light weight hydraulic piston.

5. High voltage contact. Cu-Cr to W-Cu.

6. Diesel engine cylinder.

5. High voltage contact. Cu-Cr to W-Cu.

6. Diesel engine cylinder.

VIEW MORE

You may like

-

Cable friction welding machine

-

Direct drive friction welding machine high precision friction welding machine

-

80 tons drill pipe friction welding horizontal friction welding machine

-

Cable friction welding machine

-

Automatic friction welding/stir welding machine

-

Jinan CNC Steel Pipe Friction Friction Welding Machine For Sale

-

Low cost CNC friction welding for drill pipe

-

20T biaxial friction welding machine for automobile tubular beam friction welding machine

-

Direct friction welding machine

-

Horizontal aluminum copper cable terminal friction welding machine

Other Products

-

$85000.00 / set

$85000.00 / set -

$115000.00 / set

$115000.00 / set